You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Aerate before or after pitching yeast?

- Thread starter landoa

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

McKnuckle

Well-Known Member

You can do it either way, although just before is a bit easier, as you’re not frothing up the yeast. Pouring the yeast in is fine. No need to mix it.

I aerate immediately before pitching. Never had a problem.

I aereate before pitching because I use an aerating stone which makes quite some thick froth with minuscule bubbles on the surface (like Guinness stout) and I have this probably unfounded idea that the bubbling will bring the yeast on top of the froth and I don't like it. So I first aereate, and then drop the yeast. Rationally I think this makes no sense, but my guts tell me to drop the yeast when all is ready.

Toto's

Well-Known Member

I as well aerate before pitching the yeast. You dont have to aerate if you are using dry yeast thow.

The yeast don't need to be mixed in. They will find the wort and start fermenting it.

I use dry yeast and have dumped it on top of the froth, dumped it in before aerating and then created the froth, dumped the yeast in and poured the wort on top of it, dumped it in and didn't aerate at all. Every time I got beer.

I use dry yeast and have dumped it on top of the froth, dumped it in before aerating and then created the froth, dumped the yeast in and poured the wort on top of it, dumped it in and didn't aerate at all. Every time I got beer.

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

Mix it after adding or not, it really does not matter to the quality of the fermentation or the resulting beer.

After reading a tec bulletin from the MBAA that the yeast take up the O2 immediately and that gas saturation in liquid happens at lower temps I pitch then O2. Think about it.....when I do it this way the foam layer is barely there, when I O2 first the foam is 1/8" or more.

McKnuckle

Well-Known Member

If the yeast take up the O2 immediately, then it doesn't really matter if they are already in the wort when the O2 is generated, or tossed in literally 30 seconds later. The O2 has no time to harm anything and is immediately put to use. Just don't aerate and then spend any significant time before pitching yeast, and all is well.

hoppheadIPA

Well-Known Member

This is bad advice......aerate the wort regardless of using dry or liquid yeast.I as well aerate before pitching the yeast. You dont have to aerate if you are using dry yeast thow.

I like to oxygenate after pitching either dry or liquid yeast, just prior to sealing the fermenter lid. If what is done first makes a difference in my experience I am not aware of it.

BrewnWKopperKat

(Ο_Ο)

This is bad advice......aerate the wort regardless of using dry or liquid yeast.

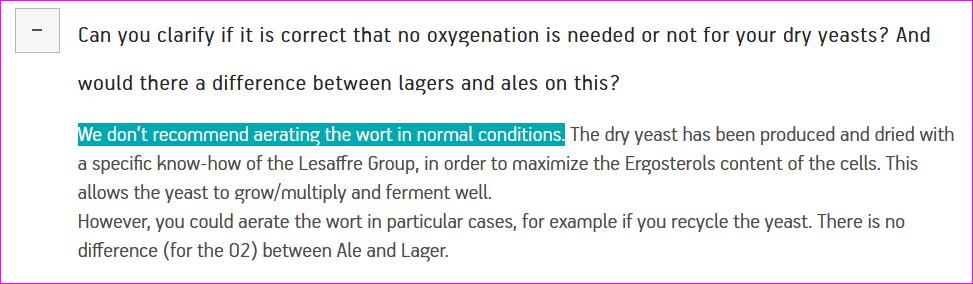

Let's see what Fermentis suggests as a starting point ...

Answers about yeast and fermentation

For Lallemand (and other strains), consider checking their web site for the latest information and use that as a starting point.

hoppheadIPA

Well-Known Member

They don't recommend it because it will hurt it? No. They don't recommend it because they don't assume it's beneficial. If it doesn't hurt, why not? It's a good practice and I've always aerated dry yeast and have always had aggressive fermentations with awesome attenuation!Let's see what Fermentis suggests as a starting point ...

Answers about yeast and fermentation

View attachment 716050

For Lallemand (and other strains), consider checking their web site for the latest information and use that as a starting point.

ChiknNutz

Well-Known Member

Along these same lines, I don't go out of my way to aerate the wort either. I predominantly use dry yeast but also don't aerate when using liquid. However, I will say that my general process does infuse some amount of oxygen as witnessed by a decent froth when finally entered into the fermenter. What I do is this:

- Manually whirlpool in the kettle to get as much trub into the center, While doing so, I intentionally splash some which helps aerate a little.

- Transfer from kettle to a bottling bucket via valve. While doing so, the wort is splashing and mixing with ambient air. So this further adds a bit of aeration.

- Transfer from bottling bucket to fermenter via spigot on the bucket. This is done in open air with bucket on a table and fermenter on the ground. This is then performing yet another bit of aeration. When doing this step, I usually stop when there's a couple gallons left, then pitch the yeast. Continue to fill the fermenter.

BrewnWKopperKat

(Ο_Ο)

It's a good practice and I've always aerated dry yeast and have always had aggressive fermentations with awesome attenuation!

I don't aerate the wort with dry yeast and I get fermentations that yield the estimated attenuation and result in enjoyable beer (never measured whether or not the fermentation started fast, was aggressive, ...).

It could be argued that aerating the wort for dry yeast is an unnecessary step in for a 'normal' wort.If it doesn't hurt, why not?

They don't recommend it because it will hurt it? No. They don't recommend it because they don't assume it's beneficial. If it doesn't hurt, why not? It's a good practice and I've always aerated dry yeast and have always had aggressive fermentations with awesome attenuation!

The logic behind the suggestion by @Toto's in #5 is that dry yeast producers, or at least Fermentis, "stuff" sterols inside the yeast so that the yeast doesn't need oxygen to produce sterols which is necessary for reproduction.

That's why they advice to oxygenate second-generation yeast: because if you recover slurry from a fermentation the sterols will already have been used by the first-generation yeast and you will have either to supply them, or to supply oxygen.

With liquid yeast, for reasons unknown to me but certainly valid, sterols are not given to the yeast (maybe because they would consume them to reproduce them inside the bag) and you have to supply oxygen (or, according to some theories, olive oil i.e. sterols).

That said, I always use dry yeast and I always add oxygen.

This is one part of my homebrewing practice where I let some instinctive measure to get in. To state it in White terms, I am one of those guys who "talk to yeast". And they tell me to oxygenate the wort

BrewnWKopperKat

(Ο_Ο)

Lallemand has a number of "Brewing Best Practices" available for download here: Downloads – Lallemand Brewing. These are in addition to the "technical data sheets" for each strain.

There's also a pitch rate calculator here: Brewing Tools – Lallemand Brewing

I did a quick review of one of the Lallemand strains I typically use: "It is unnecessary to aerate wort upon first use".

Some characteristics of dry yeast can vary by strain, so it may be worthwhile to review product information periodically.

There's also a pitch rate calculator here: Brewing Tools – Lallemand Brewing

I did a quick review of one of the Lallemand strains I typically use: "It is unnecessary to aerate wort upon first use".

Some characteristics of dry yeast can vary by strain, so it may be worthwhile to review product information periodically.

Last edited:

Lots of ways to make beer!

I always pitch wet yeast, even if using a dry yeast I’ll get it going in an Erlenmeyer flask on a stir plate first. If using liquid yeast, I’ll do a big starter, chill overnight and decant the yeast from the starter beer to minimize oxidized flavors from the starter.

I want the yeast in the wort prior to oxygenating. I don’t want any delays - I don’t want the O2 in the wort while I’m fumbling around decanting the starter, removing the stir bar or setting up my wand and O2 tank. I want the yeast already there.

I pitch the yeast at the same temperature as the wort by keeping the Erlenmeyer flask in the fermentation chamber with the carboy overnight, not to thermal shock the yeast. This gives the yeast a few minutes in the new food-rich environment before oxygenation, the goal to rapidly promote yeast O2 uptake when I oxygenate. I use a stainless beer stone on wand with a regular 5 lb O2 tank.

Either way, you’re going to make beer!

I always pitch wet yeast, even if using a dry yeast I’ll get it going in an Erlenmeyer flask on a stir plate first. If using liquid yeast, I’ll do a big starter, chill overnight and decant the yeast from the starter beer to minimize oxidized flavors from the starter.

I want the yeast in the wort prior to oxygenating. I don’t want any delays - I don’t want the O2 in the wort while I’m fumbling around decanting the starter, removing the stir bar or setting up my wand and O2 tank. I want the yeast already there.

I pitch the yeast at the same temperature as the wort by keeping the Erlenmeyer flask in the fermentation chamber with the carboy overnight, not to thermal shock the yeast. This gives the yeast a few minutes in the new food-rich environment before oxygenation, the goal to rapidly promote yeast O2 uptake when I oxygenate. I use a stainless beer stone on wand with a regular 5 lb O2 tank.

Either way, you’re going to make beer!

Last edited:

Camelot Legends

Well-Known Member

- Joined

- Jan 8, 2021

- Messages

- 81

- Reaction score

- 115

I always aerate before pitching. I’ve done both and it seems the lag time is decreasing greatly when I aerate. I also aerate before pitching because I read somewhere that pure o2 is harmful to yeast (I use pure o2 and aeration stone). All my beers are fermenting within 6 hrs. You can brew without aeration though, hence LODO method of brewing. I was interested in trying this until I read brullosophy’s experiment on it.

porterguy

Well-Known Member

Your penance is 10 "Hail Marys"... and a beer of your choice.Oh father I have to confess for I have sinned.

I never earated my wort and still brewed good beer....

.... and also bad ones.

Sweet, I might do it againYour penance is 10 "Hail Marys"... and a beer of your choice.

I'm also pitch first, the aerate. I do think aeration provides a little mixing that may be a benefit. I also don't want my wort to be sitting around with a lot of oxygen in it and no yeast to take up the oxygen in case I get called away between adding oxygen and pitching. I use both dry and liquid yeast although my liquid yeast is normally yeast I harvested from previous batch.

I did not always oxygenate when using dry yeast but have since switching from IC to counterfiller chilling. I don't have a DO meter but am guessing that going direct to fermentor in single pass through CFC I am probably starting out with a lot less O2 in the wort when I pitch the yeast than I had when I chilled with IC. And since I will harvest the yeast and may pitch it again I think even the directions linked above could be read to recommend oxygenation of dry yeast in my situation.

I did not always oxygenate when using dry yeast but have since switching from IC to counterfiller chilling. I don't have a DO meter but am guessing that going direct to fermentor in single pass through CFC I am probably starting out with a lot less O2 in the wort when I pitch the yeast than I had when I chilled with IC. And since I will harvest the yeast and may pitch it again I think even the directions linked above could be read to recommend oxygenation of dry yeast in my situation.

Yeast are probably the single biggest mystery in brewing to me, so I can just go on my experience, which says:

-Direct pitching a dry packet with no aeration will yield a good fermentation with complete expected attenuation 100% of the time

-Liquid yeast does work much faster and often better with good aeration, but is more finicky across the board

So now I only aerate when using liquid yeast. I use pure oxygen from the disposable home depot bottles for 1-2 minutes. Pull stone out, pour in decanted starter, and close it up.

Overall I find liquid yeast to be:

-More expensive for the pack

-More of a pain to handle (have to make a starter days in advance, oxygenate)

-More liquid vessels, more liquid transfers, etc, is going to increase opportunity for infection. Along this line the O2 stone in particular is highly porous and dunked in sugar water (wort) and therefore I boil it every time, just too be sure... it's always struck me as a potential infection magnet

So, I find myself using dry yeast more and more, almost any time it's an option now, because it does what I expect it to do every time and is just much less of a PITA overall.

-Direct pitching a dry packet with no aeration will yield a good fermentation with complete expected attenuation 100% of the time

-Liquid yeast does work much faster and often better with good aeration, but is more finicky across the board

So now I only aerate when using liquid yeast. I use pure oxygen from the disposable home depot bottles for 1-2 minutes. Pull stone out, pour in decanted starter, and close it up.

Overall I find liquid yeast to be:

-More expensive for the pack

-More of a pain to handle (have to make a starter days in advance, oxygenate)

-More liquid vessels, more liquid transfers, etc, is going to increase opportunity for infection. Along this line the O2 stone in particular is highly porous and dunked in sugar water (wort) and therefore I boil it every time, just too be sure... it's always struck me as a potential infection magnet

So, I find myself using dry yeast more and more, almost any time it's an option now, because it does what I expect it to do every time and is just much less of a PITA overall.

Similar threads

- Replies

- 15

- Views

- 2K

- Replies

- 9

- Views

- 1K