Yeah, that's what I reckoned. You want 500ml going into the flask, after boiling/chilling. If the water you use for your starters is clean, drinking quality, you can top up without boiling first.500ml measurement was before boiling.

If you want 500 ml in the end, you need to estimate your evaporation amount. Once the the DME (or LME) is dissolved, starter wort doesn't need to boil for more than 2-3 minutes, but you may evaporate 1-3 ounces easily in a large pot by the time it's chilled.

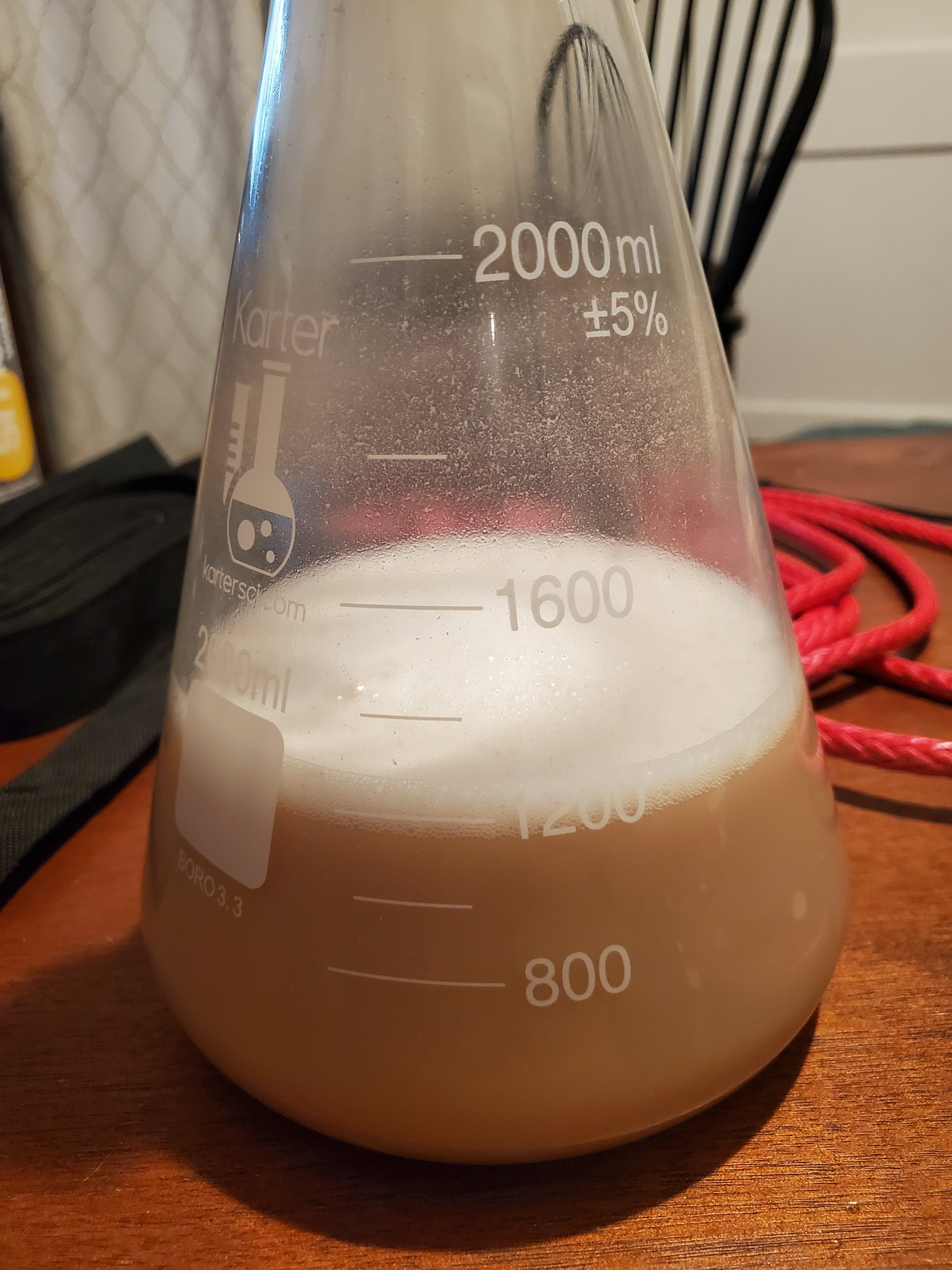

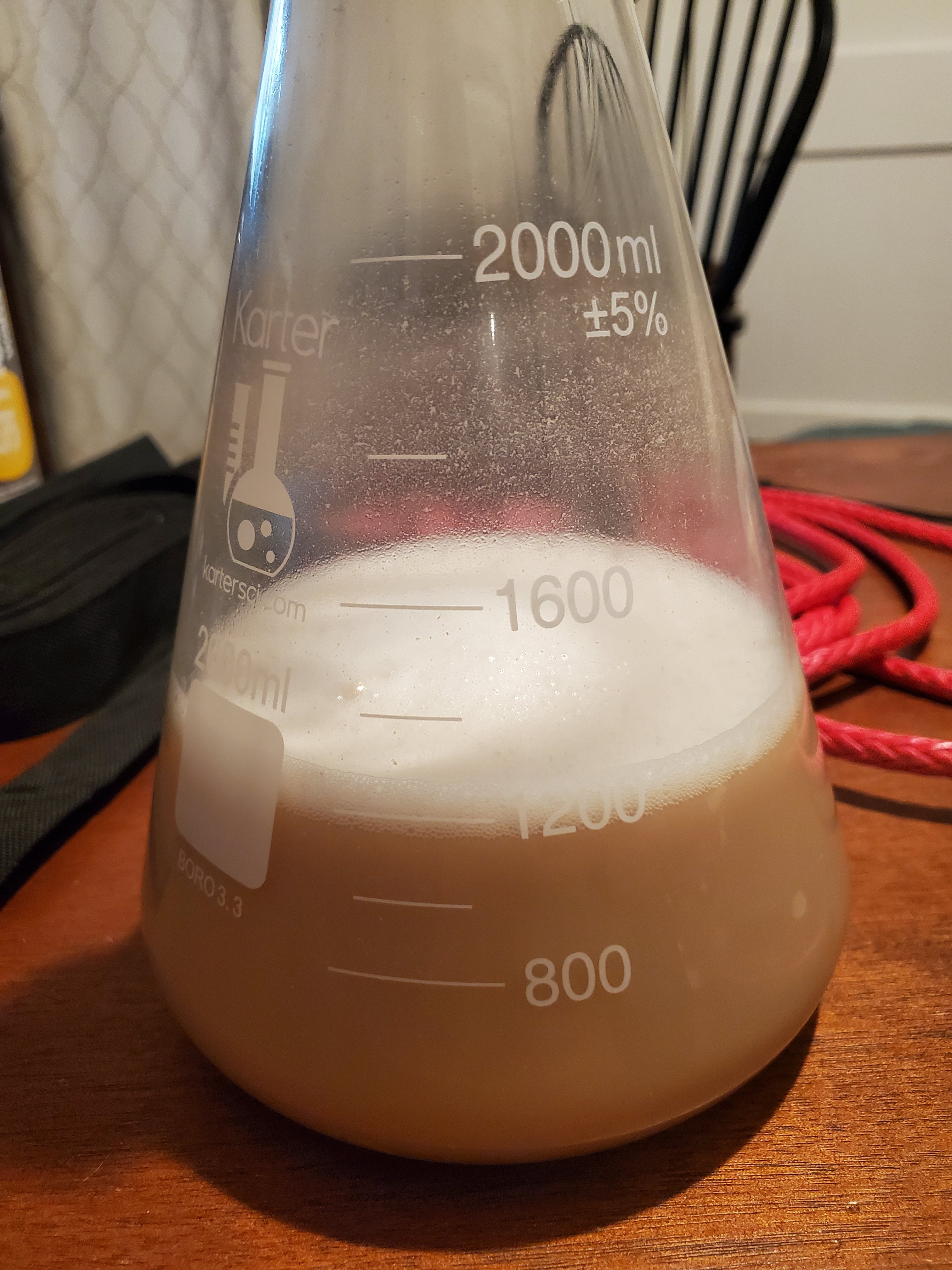

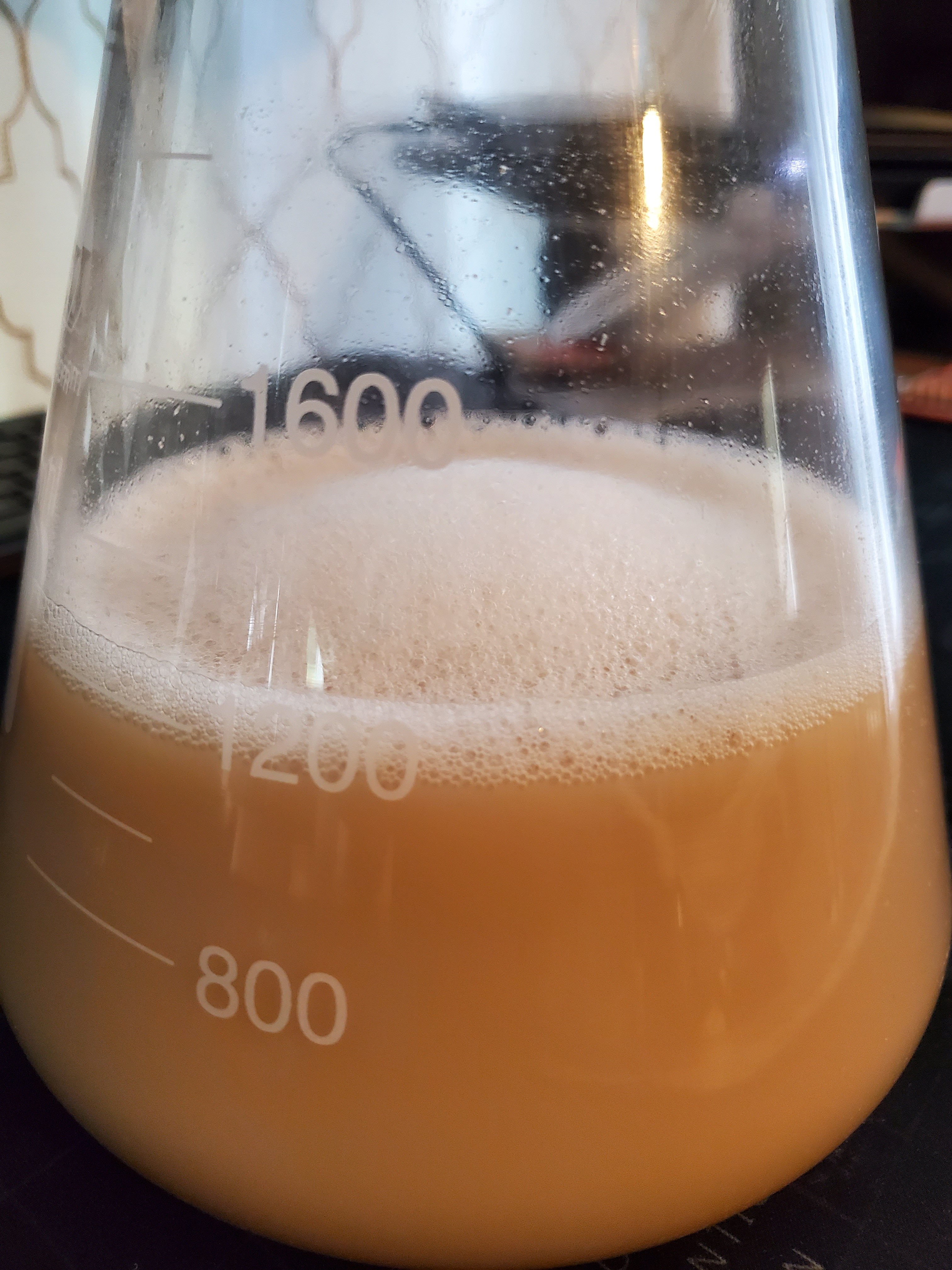

You're not going to see bubbling in a starter, but you may see tiny bubbles rising when swirling, creating a thin foam layer on top. That's a good sign, she's alive and doing her job!I didn't see much bubbling after I added the yeast

Replace it. You don't want holes in it.I also see the tin foil cap being affected by the star san I put on.

It should be loosely crimped around the flask's neck, being able to turn it. I cover the aluminum "tent" with a small piece of sanitized plastic wrap, just to cover any pinholes that may form in the aluminum foil. I have evidence of that happening.

Make sure to sanitize everything that touches the top or gets inside of the flask.

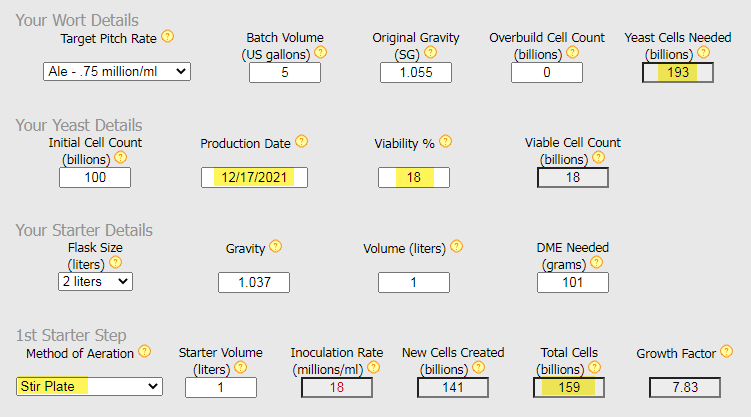

Yes it will, making a bigger starter makes more yeast. That yeast you have is over 7 months old, and was shipped. None of those help with the yeast's viability or vitality. Starters will.Will the added wort make a difference? Deciding if I should add it now.

I normally would wait with adding more starter wort until the first step is done, but since we have the accidental Starsan acidity issue, I would add it now, bringing it up to 1 liter, which will help dilute the acid and surfactant.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)