I took one of my shanks into work to see about getting the nipples grounded off. I also have some PTC fittings (as well as beer line) from Williams that's coming in Friday. I figured I'll change out both gas/beer lines.

Here's a comparison pic. There's just a slight bump left. Will that be alright, or do they need to be ground flush?

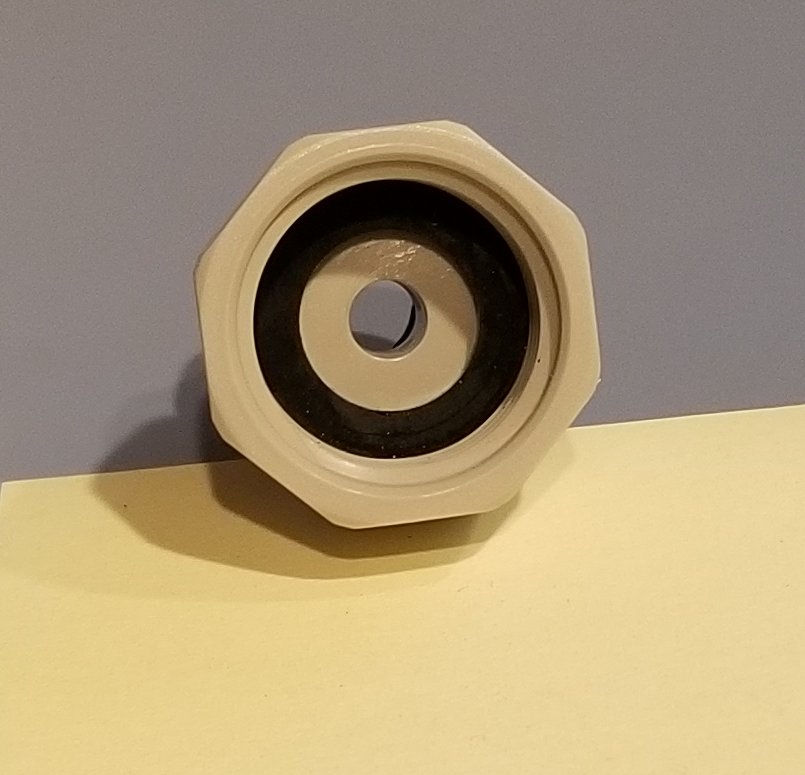

A close up for the grounded shank.

Here's a comparison pic. There's just a slight bump left. Will that be alright, or do they need to be ground flush?

A close up for the grounded shank.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)