Lallemand Brewing have just released this new product.

https://www.lallemandbrewing.com/en/united-states/product-details/abv-aromazyme/

https://www.lallemandbrewing.com/en/united-states/product-details/abv-aromazyme/

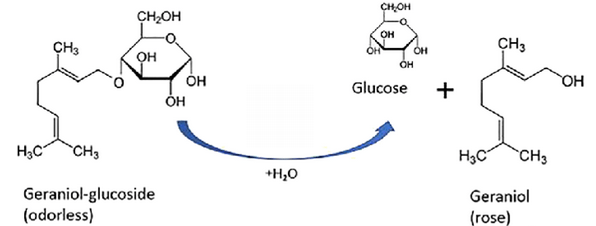

- Increases the diversity of hop flavors and aroma by changing the ratio

of specific terpene compounds - Enhances the beer mouthfeel and drinkability by reducing unpleasant harsh bitterness

- Slightly increases wort fermentability

- Expresses more character from less sophisticated hop varieties

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)