Okay so my coil came and I was able to run some water tests today. Took lots of pics and got pretty detailed data to share so here goes.

This is the coil. 10' of 1/2" In the pic both ends are taped and filled with salt. You will need to straiten it out and do this before you attempt to bend it or you will risk kinks. I was able to wrap around a nalgine bottle and just kind of make the coil stack you see here.

Here it is in the pot. It takes 1.5L of water to cover the coil to where it is in the pic and this is the amount I used for all the testing.

Silicone hose slides right on the end like barbs, no leaks or anything while I was running. Might get a 2 hose clamps to play it safe in the future though although I cant see how it would slip off or leak.

If for some reason the hose does slip off though you run a risk of pumping all your wort into your HERMS pot and then overflowing onto the burner, and in my case the outlet and pump directly under it so I seriously recommend running this on GFCI

Here are a few shots of it running

Temp probe is in a 1/2" nylon tee, I hook the output of the return onto the end of the tee so that the sensor is right before the water returns to the cooler.

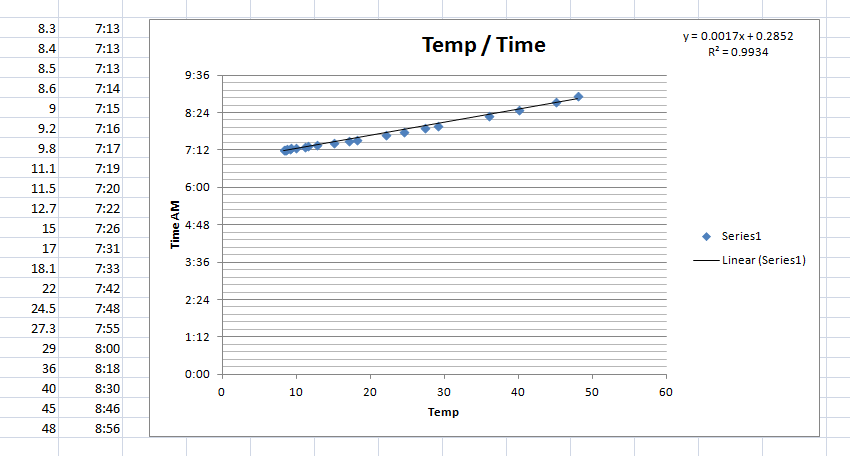

Here is the ramping data that I collected. For this I set the STC to 50c and just let it do its thing. This data is with 4 gallons of water in the MLT

Once the temp was at 50c the temp slowly keep rising until it hit 50.5c so .5c overshoot. Not too bad but not the best. However, this is with the burner set on high and the pump running a full open. I repeated the test 2 more times with the exact same results so at least it is consistent. A simple fix I found for this is, when you are 1c away from your target temp, turn the burner down to low. Doing this method I got mixed results of 0c - .1c overshoot pretty sweet. And I would imagine that you could just keep it on low to maintain temps until the next time you wanted to ramp up temps.

I'm most interested in how well the STC will function holding a temp. It would be great if you can introduce some variability like adding a cup of ice after the temps stabilize and then track how long it takes to regain the desired set point.

I'm also curious about the temp differential this setup is capable of doing - I.e. The temp of the wort before and after the hex.

It was pretty hard to test the temp holding since I'm in a cooler and it took almost ten minutes of recalculation to drop .1c however, the stc will turn the burner back on once you are .3c below target and if kept on low as mentioned above I dont see why it wont be able to hold temps to .4 - .5c no problem.

I added 1 quart of water at 17c and it dropped the temp down about 4c really fast, the stc turned on the burner and it ramped the temp back up to 50c at the speed mentioned above in the graph. As far as temp differential it was very minimal if I was pumping at full speed. Less than .1c however if I closed the valve on the outlet of my pump to almost fully closed I was able to achieve a difference of 4.5c.

Overall very happy with this system.

Pros

Cheap

Works

Double MLT as Sous vide oven

Can heat up water while sleeping or doing other things

Can hold within .4c on water test

Cons

Not super fast temp ramps

Let me know what you think of if you want more info. I will be brewing next weekend so I will be able to say for sure that it works with grain and what not and it is my hope it will even hold temps tighter since the grain will have a pretty big thermal mass. Hope this helps anyone who was curious about doing this.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)