You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

4 wire usa gfci spa box possible to convert to 3 wire?

- Thread starter Infidel

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Vincanity

Active Member

- Joined

- Sep 28, 2014

- Messages

- 43

- Reaction score

- 4

I don’t intend on going with a 50 amp breaker, I just want to feed off of the exsisting 30 amp breaker in my garage panel which is apparently a sub panel since the main breakers are on the outside of the house near my meter. I want to run a 3 prong dryer cord 10 gauge from my dryer outlet to a spa panel which has a 50 amp GFCI. The reason this would work for me is because the sub panel in my Garage is full and all the outlets in my garage are 15amp and like I mentioned previously for portability. When We’re not using the dryer I can plug in the sub panel and do what I need. Having the sub panel setup properly with 4 wire would enable me to run a heating element so I can continue to brew beer, enable me to use my welders and possibly add another circuit off the spa panel to run a couple 20 amp breakers for power tools and whatever else in the garage. When I was in Germany I ran a 3500 watt element off my kitchen outlet 220v with an auber pid with no issues, I loved it and would like to adapt that at my new place. I appreciate the advice and replies, sorry again for the confusion!

Vincanity

Active Member

- Joined

- Sep 28, 2014

- Messages

- 43

- Reaction score

- 4

I guess my question now is, would I be able to run a 10 gauge Romex ground wire from the grounding bar in my sub panel in my garage 15 ft to the spa panel to make this a 4 wire setup ? I would just run the ground wire up across the ceiling in regular plastic conduit to where I would mount my spa panel.

That’s exactly what I would do. I’m not an electrician though and I think it really comes down to what was said earlier about not going by what some guy on the Internet says. Hell I’m learning with everyone else and I’m trying to do the same thing but I guess if I die doing it then at least I wouldn’t have to listen to someone telling me that I was wrong

Vincanity

Active Member

- Joined

- Sep 28, 2014

- Messages

- 43

- Reaction score

- 4

I was thinking about the in-line gfci cable and it seemed to be more expensive that route and I’m hoping with the spa panel that I’ll be able to run a few 20 amp circuits as it seems there are 2 empty spots above the 50amp gfci. Builders took the cheap route and wired every outlet in my garage 15 amps!

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

Ok so I see in the NEC 2014 it says in order to have effective ground fault current path it would have to return to the supply source and that earth shall not be considered as an effective ground fault current path. So a ground rod alone would not work. Oops....

So I just read the code book for an hour and a half and can’t see a reason why you can’t run a ground from the sub panel but I don’t see anything that directly mentions it. IDK it’s a big ass book.....I would think that since the sub panel is grounded to the supply and the earth through the main panel that it would be the same as using the main panel. I need a beer....LOL

So I just read the code book for an hour and a half and can’t see a reason why you can’t run a ground from the sub panel but I don’t see anything that directly mentions it. IDK it’s a big ass book.....I would think that since the sub panel is grounded to the supply and the earth through the main panel that it would be the same as using the main panel. I need a beer....LOL

i would say that the existing plug is considered non-grounded. 250.130(C) allows for the running of a separate ground if changing to a grounded-style receptacle. the ground can go back to the source panel and does not have to follow the path of the circuit conductors. so if it was my, i would replace the receptacle with a 4-wire, use the existing white as a neutral and install an individual #10 ground back to the panel. per 250.120(C), that ground needs to be protected from physical damage either by being armored, in raceway or within framing members.

Vincanity

Active Member

- Joined

- Sep 28, 2014

- Messages

- 43

- Reaction score

- 4

Awesome thanks for all the info guys. I think this is the route I will take going forward. I see it as the surest safest way, Now it’ll be a matter of wiring the ground through the dry wall and finding the best way down to the receptacle. Do they sell insulated single 10g wiring? I’ll be heading to HD in the morning and I’ll try and post some pictures

Vincanity

Active Member

- Joined

- Sep 28, 2014

- Messages

- 43

- Reaction score

- 4

Found the wire bundle for the 30amp breaker! Now the question is do I remove the old wires from the panel and fish/tape a new 10/3 bundle up to that bundle and pull through the wall to the attic, cross the attic down the attic to the opening to the receptacle in my laundry room, then simply re-wire? Or find a way to get a ground wire up to the wall through the attic to the laundry? What would you do?

Attachments

i'm always in favor of 'doing it right' so if you feel you can fish that 10/3, go for it! if accessible at enough places along the route, you could tape the new 10/3 to the existing 10/2 and pull the new in as the old goes out. if you want an insulated separate ground, they definitely sell #10 awg green single conductor wire.

Vincanity

Active Member

- Joined

- Sep 28, 2014

- Messages

- 43

- Reaction score

- 4

To be honest I think that will be the easiest route, by installing new wire. I’ll figure out how to turn off power to the sub panel tomorrow. I looked at the main breaker panel and didn’t see any large size breaker for the sub panel in my garage. Maybe I’ll just turn them all off to be safe when installing the new wire

The sub panel has to be fed from the main panel so there must be a breaker in there. You can have a pretty hefty breaker in a pretty slim package these days and sometimes the numbers are hard to see. The easiest way to find the breaker is with a breaker tracer (plug one part into an outlet in the garage and then run the other part over the breakers in the main panel until you find the one that beeps loudest) but that represents an investment you probably won't want to make (https://www.amazon.ca/dp/B005G7SC0M/?tag=skimlinks_replacement-20). You can always turn the main panel breakers off one at a time until you find one that darkens the garage. An investment you should make is in a non contact voltage tester. After disconnecting the power for service verify that it is indeed disconnected with this little gadget (after having verified that it is working by testing it on a live outlet).

Last edited by a moderator:

Vincanity

Active Member

- Joined

- Sep 28, 2014

- Messages

- 43

- Reaction score

- 4

I now have 4 wire! It wasn't as difficult as I expected, being that I had no help I kept going up and down the attic fishing the wire through. They had the wire stapled to the 2x4 going down to the laundry room outlet, I was a little frustrated but popped the staples out by wrapping the end of the old wire bundle with a pipe wrench and hammering down on it. That worked and was able to get the new wire through with no problems. I found the main breaker to the sub panel in the garage, it was a 2 pole 90 amp breaker. Killed that and the 30 amp in the sub panel. I wire everything up at the sub panel and installed the new 4 wire in the laundry room. Turned power back on and ran a load in the dryer just to ensure everything was ok. Seems everything is fine! I'll be working on the spa panel box tomorrow!!! Cheers

Attachments

I don't see either the non contact voltage tester or the circuit breaker tracer in the Home Despot basket. You have to understand that one of the most important parts of home brewing is collecting gadgets! But I'm delighted that the project went smoothly.

Vincanity

Active Member

- Joined

- Sep 28, 2014

- Messages

- 43

- Reaction score

- 4

Your right I should have at least got the non contact voltage tester and I had every intent in doing so, I always gets so dis tracted at HD. I realized that when I got home but felt very confident finding the breaker to the sub panel in my garage and turning off the 30 amp breaker. Everything went fine, I’m confident I could re wire the 15 amp breakers in my garage if I wanted. Today I will be building my spa panel box. I’ll post pics later so you guys can critique my wiring haha!

Vincanity

Active Member

- Joined

- Sep 28, 2014

- Messages

- 43

- Reaction score

- 4

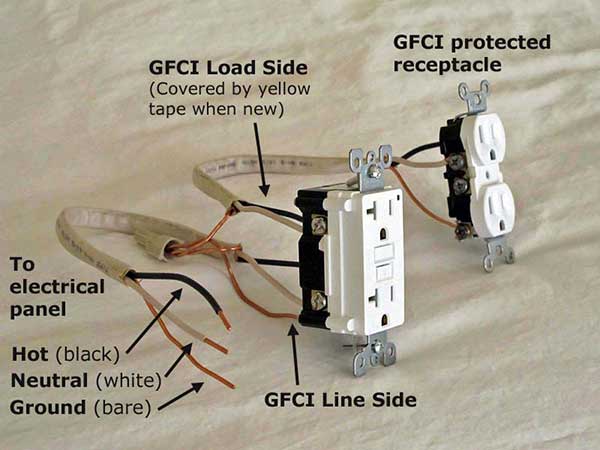

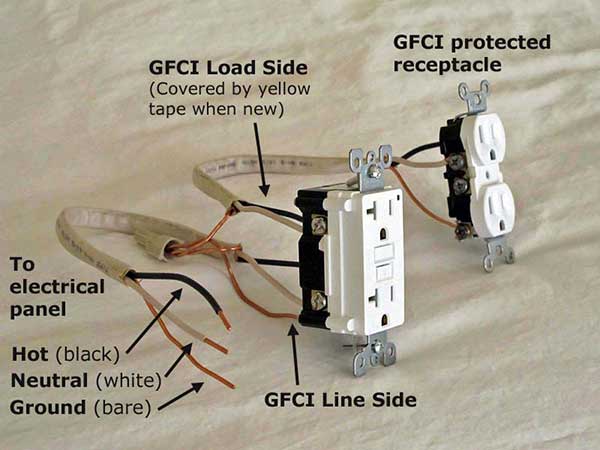

Built the panel today. I mounted the 220v socket and 20 amp gfci sockets to the panel itself. I wired everything up, the only question I had was the yellow tape across the bottom part of the 20 amp GFCI socket. I followed the terminals on top and wired the black hot to the 20 amp breaker, ground to ground bar and neutral to neutral bar. Tomorrow I will run the 10/3 romex from the laundry room through the wall to where I will mount it in my garage.

Attachments

the yellow tape is covering the load terminals on the receptacle. these are 'downstream' of the gfci circuitry so they are gfci protected. basically, they are used if you want to continue the circuit to other receptacles so you shouldn't need to use them. those receptacles can be 'regular' receptacles but will still be gfci-protected. it is a way to save costs, as opposed to buying a gfci receptacle for all locations. if the circuit was continued off of the line terminals (the ones you used), downstream receptacles would not have gfci protection.

Vincanity

Active Member

- Joined

- Sep 28, 2014

- Messages

- 43

- Reaction score

- 4

Ah got it, thanks for the clarification! @itsnotrequired sure learning a lot about electricity! Gonna finish the project up today and hopefully test boil some water and my welders

Vincanity

Active Member

- Joined

- Sep 28, 2014

- Messages

- 43

- Reaction score

- 4

Finished up the Spa Panel! Mounted the panel, wired everything up and tested the 50 amp GFCI by pushing the test button and it tripped like its supposed to. I then plugged in a GFCI tester to the 20 amp socket and everything works great! Plugged in my 115v Lincoln MIG to the 20 amp socket and it fired up just fine. The real test will be doing a boil from one of my kettles that has a 3500watt element installed, only issue is I will have to make a trip to HD to get new 10 Gage flexible wiring as the wiring I have my element hooked up to is European 2.5mm which is equivalent to 14 guage AWG. This confuses me because this was the gage wire recommended for running an element off of the 220v in Europe. Maybe they have a different standard?

Attachments

processhead

Well-Known Member

Running your 3500 watt element on 240 volts will pull 15 amps, which is right at the nominal ampacity limit of a 14 gauge service cord.

You would be better off with a larger cord, although you were probably safe for intermittent-duty operation.

A 12 gauge service cord is certainly adequate for a 3500 watt element.

You would be better off with a larger cord, although you were probably safe for intermittent-duty operation.

A 12 gauge service cord is certainly adequate for a 3500 watt element.

2.5 mm2 is slightly larger than 14 awg. 16 amp is a standard breaker size in europe, works fine with a 2.5 mm2. all that aside, get yourself a #12 awg cord.

Vincanity

Active Member

- Joined

- Sep 28, 2014

- Messages

- 43

- Reaction score

- 4

Awesome makes sense! Thanks for all the helpful advice and knowledge guys, hopefully this will help out someone else down the line. Another question, If I wanted to run an extension cord how much would I have to worry about voltage drop? Say If I wanted to move my brew cart outside I would probably need a 20-25 ft extension cord to get me outside.

Last edited:

at those lengths and with a 'standard' cord, voltage drop shouldn't be an issue. the real impact of reduced voltage is reduced power output at the element. worst case, it will take slightly longer to heat compared to full voltage.

processhead

Well-Known Member

Agree with itsnotrequired.

Using an extension cord, you will see a longer time to reach boil, but should be adequate power to maintain that boil once you reach it.

You can minimize the effects of using an extension cord by using a heavier 12-3 cord.

Using an extension cord, you will see a longer time to reach boil, but should be adequate power to maintain that boil once you reach it.

You can minimize the effects of using an extension cord by using a heavier 12-3 cord.

Last edited:

Similar threads

- Replies

- 14

- Views

- 3K

- Replies

- 3

- Views

- 3K

- Replies

- 9

- Views

- 2K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)