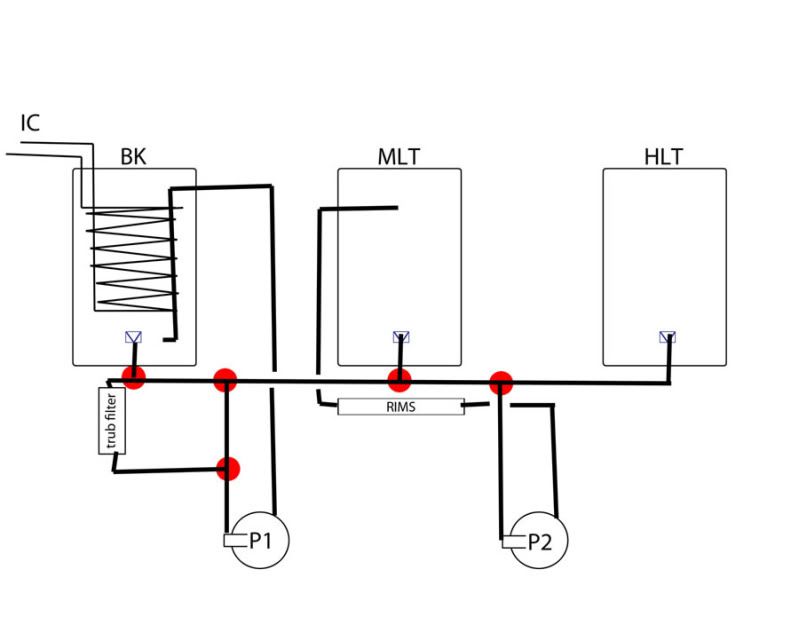

I have been planning a single tier RIMS build and while drawing up my flow diagrams i realized that with what i want to do i might be better off using a few 3-way ball valves instead of twice as many standard ball valves and tees. Anyone else use these are there any pros/cons i should consider to either setup?

here are two that i have been considering

http://www.amazon.com/T-Type-3-Way-Stainless-Female-SUS304/dp/B0075DNEY4

http://www.homebrewing.org/Blichmann-3-way-Ball-Valve_p_2092.html

here are two that i have been considering

http://www.amazon.com/T-Type-3-Way-Stainless-Female-SUS304/dp/B0075DNEY4

http://www.homebrewing.org/Blichmann-3-way-Ball-Valve_p_2092.html

Last edited by a moderator:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)