Well the first brew is done! It was also my first brew ever. After a year of reading, listening, and watching I dived into the deep end.

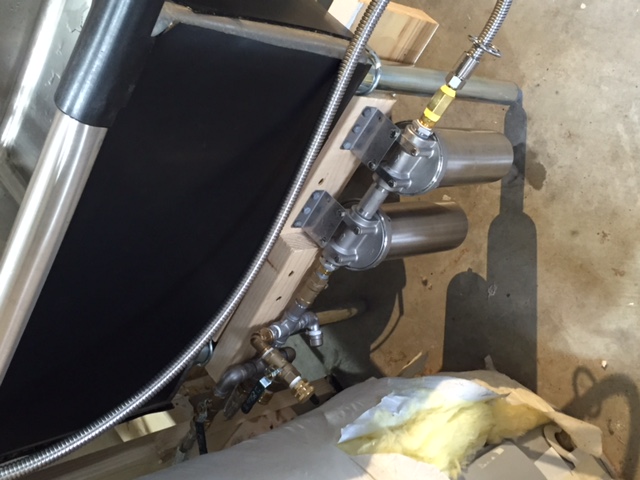

I have attached some pictures of the system I and my brother in law are building.

Some newbie goof ups were, dumping trub using the full port ball valve into a SS bowl - bad idea, the bowl did an outstanding job of directing the stuff everywhere!

Did not adjust the lid band clamp correctly, so I never had a single bubble out the blow off hose, but by golly the hydrometer kept saying fermentation was cranking.

Rushed and did not let the wyeast smack pack do its job.

We tried to lift the colender out by hand, even though we went to all the effort to install that hoist in the attic.

Really need to figure out a way to deal with fluid in hoses, more wort on the floor.

Supposed to have 11 gallons of beer, but wound up with 6.5, still scratching my head on that one, oh wait, my brother in law used 12oz samples for hydrometer readings. From the notes maybe hourly.

The important thing is that we got 6.5 gallons of a nice golden ale, somehow hitting the OG and FG. We are taking 5 gals up to my nephews graduation from West Point next week.

Need to figure out the Beer Smith settings tweaks. Pretty sure I should have had more water to start with.

Scotch Ale is next.

If you are using beersmith, I highly recommend downloading the BIAC equipment profile. Others have already put in the effort to create the profile for it, so no need to try and reinvent the wheel. RO water will need some salt additions. How fast does it come out the system. I would still even recommend getting a water test (ward labs or someone local). For 40 bucks you can confirm what your water is coming out of your filtration system to adjust salts according to the beer style you are making.

Brewing salts for RO will likely be needed for anything beyond pilsners. CaSO4, CaCl2, NaCL, MgSO4, CaCO3 will likely all have to be put in for many styles. Look up sulphate to chloride ratios to get a better sense of flavor adjustments with water.

Also, a refractometer is a worthwhile investment, I don't use the hydrometer until I am finished with pumping my wort to fermenters and drain my hosing for the reading (less loss). Two drops of wort on your refractometer (dont buy the cheapest one) will tell you where your gravity is throughout the process. I take both hydrometer and refractometer in the end to confirm both readings are correct, or at least off in the same way.

I had a low yield first few times too, I realized I was mashing too thickly and sparging too heavily. Now, when I make a 15-17 gallon batch I still only use <5 gallons to sparge and about 18 gallons to mash 34 lbs of grain. These are not solid numbers to be repeated to a T but they might be ballpark ones you can use as a baseline to work from.

Here comes another recommendation, invest in a pH meter with buffering solutions (7.01 and 4.01). This will ensure you can acidify your water to 5.2 to 5.6 depending on the style. It will improve mash efficiency (for me by almost 30%!) and give you more data to work with when fine-tuning your craft with your equipment.

Brew expecting for some loss, I lose between .25 and .75 gallons depending on the trub content. More than that and there is something you will learn to do differently that will improve your efficiency. Also, cranking your power box on 100 will boil more wort off than I was used to when I got the system. I like a good vigorous boil so I mash thinner to account for evaporation.

Oh, and dumping trub, we use the rubbermaid bins (4 gallon) which help. They slide under the lowest valve and the perpendicular walls reduce spillovers. Hope this helps, keep brewing on it, you will learn something new every time! My last two batches I got a brewhouse efficiency of 77% and 79% using these methods. Some people can push that to the mid 80s but I haven't gotten there yet.