Do you have a parts list for this build?

No, only what is in the schematic in the original post.

Do you have a parts list for this build?

It helps to consider the water analogy again:

voltage (volts) = pressure, (psi)

current (amps) = flow (gpm)

resistance (?) = resistance (ohms)

I.e., I = 5500W / 240VAC = 23A.

I liked the water analogy. Would it give a better picture by stating it this way?

voltage (volts) = pressure, (psi)

current (amps) = flow (gpm)

resistance (ohms) = resistance (pipe diameter)

Does anyone know if an electric system can be done safely on a 3 prong system? We have an old 1950's house and they only have 3 prong 240v outlets. If I have an electrician install a GFCI breaker in our panel would this provide the protection I need?

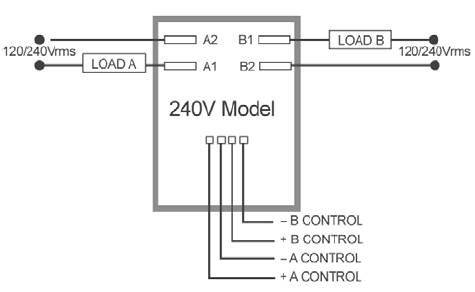

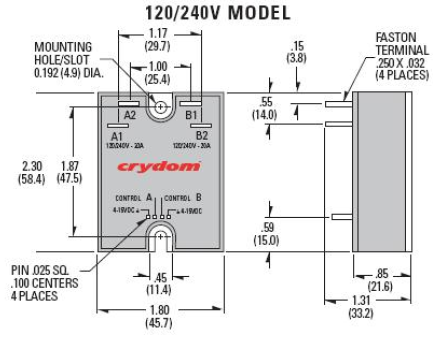

Hey Passedpawn, I'm trying to put together something similiar for a friend. He has 4 5500W elements all on their own 240V-30A breakers. Planning on putting 1 PID to control all 4. Will we need 4 or 2 D2425D SSR's to handle the load. I like the idea of having both legs being controlled. Is the D2425D rated for 25AX2? Also a single SSR has 4 connections, Does the dual have 6? Having trouble understanding the Dual SSR. Thanks

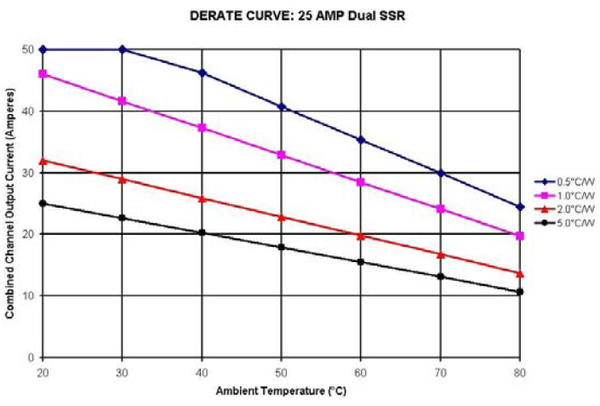

Got it. Great explanation. So to run 4 5500W elements on 1 PID: Jumper the inputs to 4 25A- DSSR's. Will we need 2 of the heatsinks you posted?