handbrewing

Member

Hi,

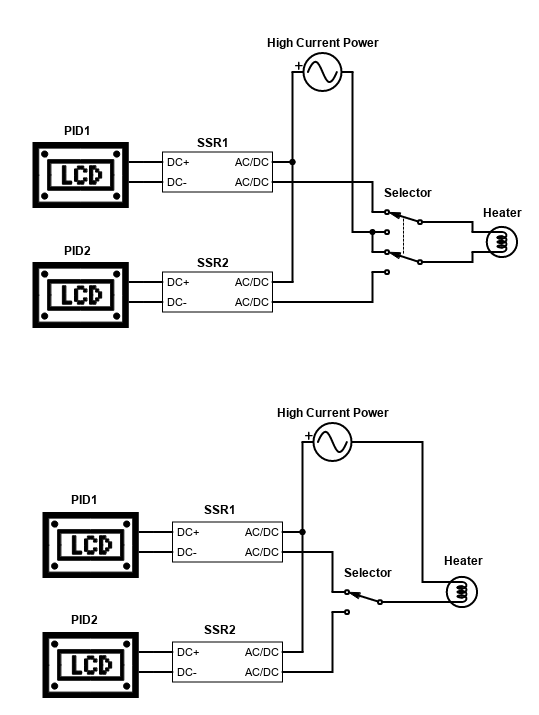

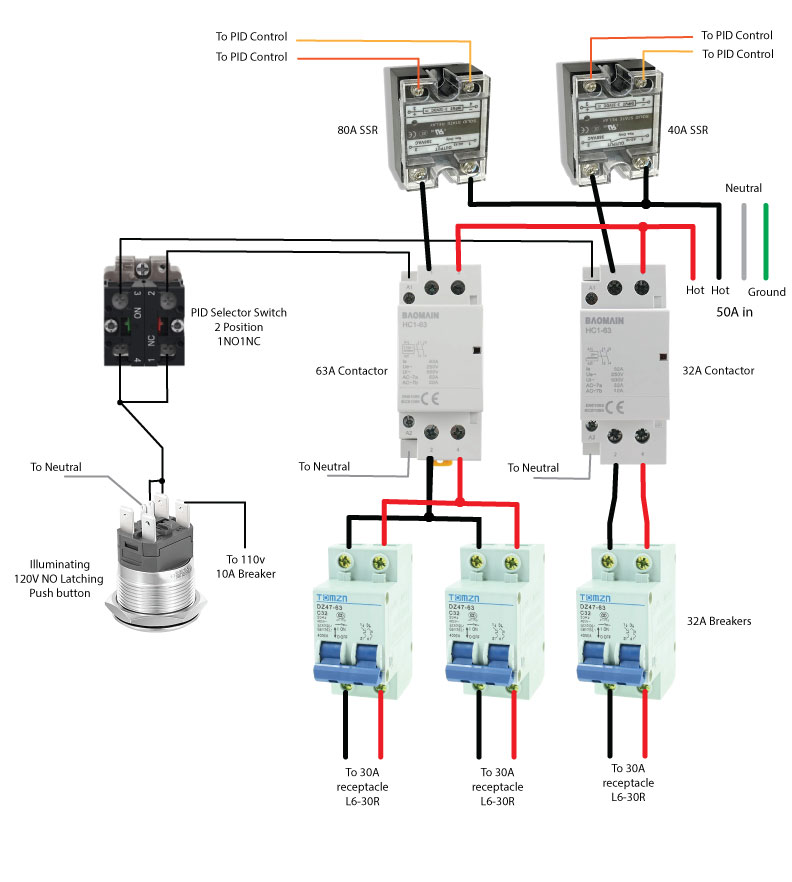

I’m looking for a wiring diagram for the below controller setup.

50amp controller with 2 PIDs and 2 SSRs.

The PIDs will have a selector switch that turns on the PID that’s selected.

I’d like to have a single stitch that fires the elements that has the selected PID on and assigned to its respected elements.

Similar to the Ssbrewtech controller that has one push button that fires the elements on and selector switch for the PIDs

So only 1 element switch total. The elements that fires is the one for the PID that’s on with the PID selector switch.

I have most of the controller wired using contactors but can’t wrap my head around the single element switch wiring.

Thanks!

I’m looking for a wiring diagram for the below controller setup.

50amp controller with 2 PIDs and 2 SSRs.

The PIDs will have a selector switch that turns on the PID that’s selected.

I’d like to have a single stitch that fires the elements that has the selected PID on and assigned to its respected elements.

Similar to the Ssbrewtech controller that has one push button that fires the elements on and selector switch for the PIDs

So only 1 element switch total. The elements that fires is the one for the PID that’s on with the PID selector switch.

I have most of the controller wired using contactors but can’t wrap my head around the single element switch wiring.

Thanks!