Did you do the boil with the box open?

On another note, let's try to keep this civil. Anyone building something like this is taking a risk. It's clear that you should err on the side of caution if unsure....

Passedpawn: Do you think the plastic box is better than a metal toolbox, a la "simple brewing"?

Boiled with the box closed. After more than an hour, I cut power and immediately measured temps (with an infrared temp gun) and also reached into the box and felt the wires, terminal blocks, etc. Nothing was hot at all.

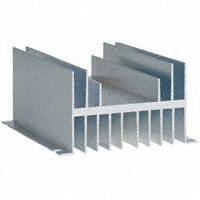

I love the plastic box. Love love love. The metal box was a major pain to build and, in the end, felt a little clunky. I was concerned that the plastic wouldn't take the heat of the heatsink, but in testing this wasn't an issue. I considered adding a fan after I tested it, but I now see I don't even need that.

I'll be brewing 1 (maybe 2) batches this wkend. If there is anything else to add, I'll post here.

Yep, steve, err on the side of caution is great advice. BTW, did you look at my schematic? Do you see how I'm using the one PID for both elements?

[edit]

Here's the old crappy one. This one had 10 AWG wiring. I hated this thing, although it worked well.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)