Seems to me that you didn't bring the temperature down far enough with the water before you chilled the rest of the way in ice. If the temperature isn't down below boiling most of the water will have boiled off as it is cooling the syrup. WHen that happens, there is not much left to keep the sugar liquid. Try going down to 220 and then chilling. I'll be that works better. Just a guess.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

20 lb of sugar and a jar of yeast nutrient

- Thread starter SnickASaurusRex

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I think I am missing something on this procedure.

I am pretty sure I followed the instructions correctly but I am creating a semi-solid instead of a syrup.

Did 2lbs with 1 cup of water + 1 tsp dap, cooked to 290, added 1/2cup of water and stirred in good as soon as the meter hit 290. Temp dropped to 240 and I put it in the ice bath.

Poured it into the mason jar while still warm, it is now a semi-solid in the jar. Not really sure how I am going to get it out.

it just probably crystalized.. try heating the jar in a pot of hot (boiling) water

orangehero

Well-Known Member

If it's crystallizing then you didn't get enough inversion. You can try adding more DAP, adding an acid, heating at a slightly slower rate, or doing the double cook. Or you can do the inversion process first and go from there. Also this question has been addressed in the thread.

Wait, is it crystallized or is it just too thick? Those are two very different things. Certainly the capacity to crystallize is dependent upon the degree of saturation and therefore amount of water. But crystallization should be obvious.

It was crystallized.

I loosened it out of the jar with some boiling water and lots of elbow grease.

I re-cooked it but this time I added 1 cup of water at the finish instead of the 1/2 cup from the recipe, it got it down to 220.

I got syrup this time.

I loosened it out of the jar with some boiling water and lots of elbow grease.

I re-cooked it but this time I added 1 cup of water at the finish instead of the 1/2 cup from the recipe, it got it down to 220.

I got syrup this time.

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

The ability of "supersaturated" solutions to stay crystal free often depends upon whether there are any crystals or small particles for new crystals to form on. Also on temperature. I would think that if you have a nice clean syrup and store reasonably warm it should stay for a very long time. If it does crystallize, you can just warm it up. It's also pretty difficult for microbes to grow in this high a concentration of sugar and there are probably none there if you bottled it in clean bottles when the syrup was still very hot.

rshortt

Well-Known Member

Hey everyone. A month or so ago I made a couple pounds of sugar #5 and it turned out really, really well. I was very happy with the complexity of flavour.

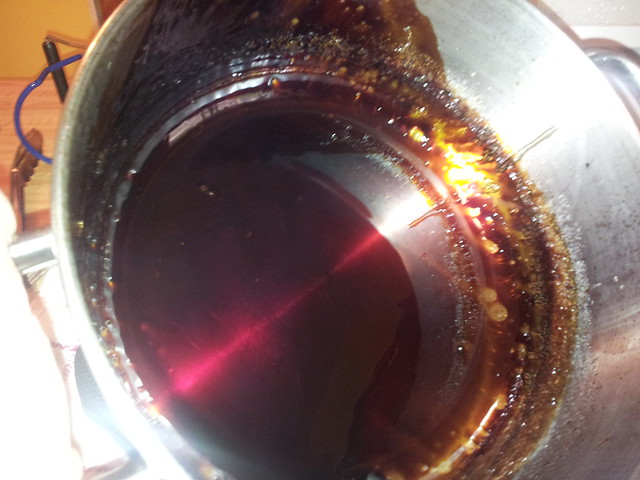

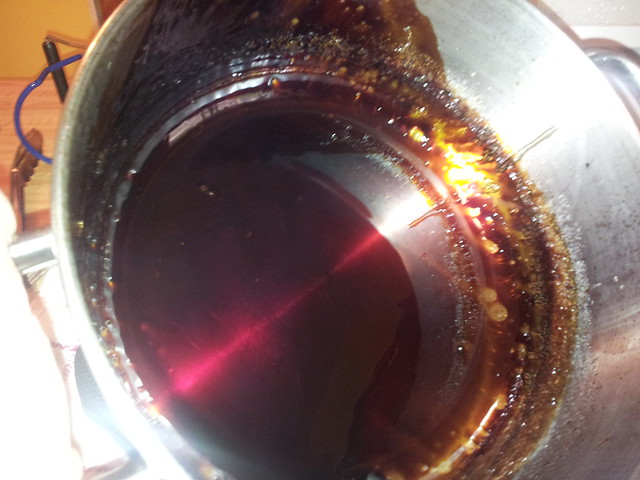

Candi Syrup Starting to Boil by Hot Pepper Daddy, on Flickr

Candi Syrup Almost Done by Hot Pepper Daddy, on Flickr

Nice Colour by Hot Pepper Daddy, on Flickr

I then brewed my first Dubbel (included 800g, almost 2 lbs), which is now on tap. I'm very happy with this brew!

Abbey Dubbel by Hot Pepper Daddy, on Flickr

I'm making another 4 lbs of this today. Thanks for all thr work on this everyone!

Candi Syrup Starting to Boil by Hot Pepper Daddy, on Flickr

Candi Syrup Almost Done by Hot Pepper Daddy, on Flickr

Nice Colour by Hot Pepper Daddy, on Flickr

I then brewed my first Dubbel (included 800g, almost 2 lbs), which is now on tap. I'm very happy with this brew!

Abbey Dubbel by Hot Pepper Daddy, on Flickr

I'm making another 4 lbs of this today. Thanks for all thr work on this everyone!

orangehero

Well-Known Member

edecambra said:So that article says that a variety of amino acids are necessary for the flavors. What about using the food type amino acids from whole foods or something

AFAIK, it just needs a source of nitrogen for the maillard reaction.

Here's more current work being done on candi syrup at home.

that article seems to say that only burnt sugar flavors are possible unless you do it their way. funny.. never got burnt sugar flavors following the instructions in the OP.. the article also gives references to time. but what about temps? if you have no temp control then yes you will burn the sugars quickly.

as always, there are more than one way of accomplishing the same goal. for me DAP and temp control as described in the OP works for me, this might work for you but for the article to say they're the only right way is laughable

Whipskipper

Member

Hello I am not sure on what kind of sugar to use for this candi syrup? Corn sugar I using for priming or just regular store bought white sugar

Thanks

Thanks

Hello I am not sure on what kind of sugar to use for this candi syrup? Corn sugar I using for priming or just regular store bought white sugar

Thanks

traditionally beet sugar is used to produce candi sugar and candi syrup is the by product of candi sugar production. For making it at home and following the directions given here, plain store bought sugar will work. Unless the package says Cane Sugar then chances are good that it's beet sugar.

WileECoyote

Well-Known Member

Nicely done.

Cheers

Cheers

A word to the wise for those of you living at altitude: Decrease all of the temperature 1 deg F for every 500ft in altitude. I live at 5000ft and my first attempt at deep amber came out way dark and the syrup was thicker than molasses. I found out you need to adjust candy temperatures when you live at altitude, so I knocked down my terminal and soft ball temps by 10 degrees. The next batch was right on the money.

jtp137

Well-Known Member

rshortt said:Hey everyone. A month or so ago I made a couple pounds of sugar #5 and it turned out really, really well. I was very happy with the complexity of flavour.

http://www.flickr.com/photos/nspeppers/8175844399/

Candi Syrup Starting to Boil by Hot Pepper Daddy, on Flickr

http://www.flickr.com/photos/nspeppers/8175849399/

Candi Syrup Almost Done by Hot Pepper Daddy, on Flickr

http://www.flickr.com/photos/nspeppers/8175884950/

Nice Colour by Hot Pepper Daddy, on Flickr

I then brewed my first Dubbel (included 800g, almost 2 lbs), which is now on tap. I'm very happy with this brew!

http://www.flickr.com/photos/nspeppers/8256562949/

Abbey Dubbel by Hot Pepper Daddy, on Flickr

I'm making another 4 lbs of this today. Thanks for all thr work on this everyone!

I am thinking about doing a double with sugar 5 and just pilsner malt. What do you think about the srm of sugar 5 is it dark enough

Brew-ta-sauraus

Well-Known Member

My homebrew store sells LD Carlson brand Yeast Nutrient which says it contains food grade urea and Ammonium phosphate. Is the the same as DAP??? Can i use this yeast nutrient to make the candi sugar?

Brew-ta-sauraus

Well-Known Member

Ok I went ahead and tried to make this syrup with the LD Carlson yeast Nutrient. I followed the OP instructions exactly. I live at 6288 feet above sea level so I used the high altatude instructions and cooked too 240 degrees. I got syrup but no color. I ended up cooking to 250 degrees and still just a slight bit of color. I cooled the syrup and it basically hardened to a chewy consistancy. It was not liquid any longer but thick. Im going to buy the DAP and try again as that is the only thing that I can think of that changed my attempt.

rshortt

Well-Known Member

I am thinking about doing a double with sugar 5 and just pilsner malt. What do you think about the srm of sugar 5 is it dark enough

I wish I could judge the SRM but this stuff is really, really dark. I think my last batch was darker.

aubiecat

Well-Known Member

Just made 2lbs. of #5. That was pretty easy. My son tasted it and he said it tasted like berries.

Got a Belgian dark strong ale coming up next weekend. I'll see if it stays in a syrup liquid state after it cools.

Got a Belgian dark strong ale coming up next weekend. I'll see if it stays in a syrup liquid state after it cools.

that article seems to say that only burnt sugar flavors are possible unless you do it their way. funny.. never got burnt sugar flavors following the instructions in the OP.. the article also gives references to time. but what about temps? if you have no temp control then yes you will burn the sugars quickly.

as always, there are more than one way of accomplishing the same goal. for me DAP and temp control as described in the OP works for me, this might work for you but for the article to say they're the only right way is laughable

The only things that that Ryan's blog really adds is the addition of lime to the equation; and confirms that adding acid only (like cream of tarter) creates burnt sugar flavors (candy apple).

I have been following the procedure outlined on the first page of this thread for several batches now but with a small addition of lime + the outlined addition of DAP and have found that my results have been better.

The only things that that Ryan's blog really adds is the addition of lime to the equation; and confirms that adding acid only (like cream of tarter) creates burnt sugar flavors (candy apple).

I have been following the procedure outlined on the first page of this thread for several batches now but with a small addition of lime + the outlined addition of DAP and have found that my results have been better.

How much lime are you using per batch? On Ryan's blog he states that the lime additions most likely won't scale linearly. I also wondered the same thing about DAP additions. I would like to make 10 pounds of the deep amber syrup. Any suggestions on amounts of DAP and lime for this amount of sugar?

Or anyone with negative results from using lime?

I made 10 pounds of dark candied syrup a few years ago and scaled DAP linearly with the original recipe on this thread. The ammonium was overwhelming. I had to open doors and windows of the apartment and ended up shooting way over the target temp. Ended up turning out really good though and made some great beers with it. My batch lasted over a year and no apparent change in flavor over time.

Well I made a batch last night. Here's my notes:

Belgian Candied Syrup

Deep Amber (290F)

10# Sugar

5 cups water

10 tsp DAP

1. Mix sugar and water

2. Add DAP around 210F

3. Heat to 250F on high heat

4. Turn heat down a bit so you can slowly build up to target temp

5. Heat to 290F and remove from heat

6. Slowly add water until temp drops to 210-220F

7. Reheat to 237-240F then allow to cool (This will evaporate enough water to create a consistent syrup and avoid crystallization when cooled)

8. Transfer to a sanitized preheated mason jar

Notes:

• Syrup weighs 12# 4oz

• Heated to 295F because 290F didn’t seem dark enough. Even after removed from heat the syrup with continue to darken until cooled. 295F target temp is a little darker than I wanted. Try 285-290F next time.

• Could not find lime at the grocery store. Order online before making next batch.

• Use 12.5 tsp DAP next time, did not have as strong ammonium aroma as the last batch. It was strong but not overpowering.

Belgian Candied Syrup

Deep Amber (290F)

10# Sugar

5 cups water

10 tsp DAP

1. Mix sugar and water

2. Add DAP around 210F

3. Heat to 250F on high heat

4. Turn heat down a bit so you can slowly build up to target temp

5. Heat to 290F and remove from heat

6. Slowly add water until temp drops to 210-220F

7. Reheat to 237-240F then allow to cool (This will evaporate enough water to create a consistent syrup and avoid crystallization when cooled)

8. Transfer to a sanitized preheated mason jar

Notes:

• Syrup weighs 12# 4oz

• Heated to 295F because 290F didn’t seem dark enough. Even after removed from heat the syrup with continue to darken until cooled. 295F target temp is a little darker than I wanted. Try 285-290F next time.

• Could not find lime at the grocery store. Order online before making next batch.

• Use 12.5 tsp DAP next time, did not have as strong ammonium aroma as the last batch. It was strong but not overpowering.

rshortt

Well-Known Member

csamson, what size pot did you use and were there any issues with with cooking that much sugar?

csamson, what size pot did you use and were there any issues with with cooking that much sugar?

I used a 7.5 gallon turkey fryer that I used to do my 5 gallon boils in. Probably didn't need a pot that deep. I used a 5 gallon pot the first time and came close to boiling over. However, I know my temps were too high the first time now so I think you could get away with using a 5 gallon pot.

I didn't have any issues with the amount of sugar other than it took longer to get to target temp. You could probably make 20# in a turkey fryer and be fine if you really wanted.

aubiecat

Well-Known Member

How much time does it take to make a 1 Qt. Batch of the sugar #4's? I was thinking of taking a crack at it but wanted to know how much time to alot.

1 qt. is around two pounds. Should take about an hour.

It takes a while for the water to evaporate out of the sugar.

jtp137

Well-Known Member

Does anybody know what temperature would give you an srm equall to D-45 syrup and D-90 syrup. Want to make 10 gallon Rochefort 10 clone and I dont want to spend 50 dollars on sugar

Similar threads

- Replies

- 14

- Views

- 848

- Replies

- 7

- Views

- 1K

- Replies

- 6

- Views

- 2K