I'm not 100% surprised by the issues. SS seems to come out with a new product weekly. Unless you have a staff of 20 engineers there's no way these products are being tested properly. Some of the QC is also disheartening. I like my Brew Bucket but probably gunna hold off on ordering more until they take step back and test their products.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

20 gallon SS Brewtech Infussion mash tun

- Thread starter ccfoo242

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

ccfoo242

Well-Known Member

Seems like the heater isn't working at all. If you remove the bottom panel can you feel any heat from the heater pad thingy when its on? Or with no heat applied does the temp drop more? My replacement arrives Friday and I'll test it too. Though I didn't buy the heater.

Seems like the heater isn't working at all. If you remove the bottom panel can you feel any heat from the heater pad thingy when its on? Or with no heat applied does the temp drop more? My replacement arrives Friday and I'll test it too. Though I didn't buy the heater.

I think the heater is working. I turned it on with nothing in the mash tun and when I put my hand on the bottom of the tun it is hot to the touch. The heating pad is really quite small though. It can't be more than 10" in diameter. In fact, when I first saw it I was wondering in the back of my mind how a tiny little silicone pad could hold or increase temperature in this giant mash tun. Really my expectation from the get go though was just to be able to hold temps - I guess that is why this is so disappointing because I consistently seem to be losing several degrees which for me is a step backwards. I haven't tried it without the heater. I may do that because if the results are the same, I might as well return the heater! I'm very interested to hear how the mash tun performs for others.

ccfoo242

Well-Known Member

That's a real bummer.

augiedoggy

Well-Known Member

I'm not 100% surprised by the issues. SS seems to come out with a new product weekly. Unless you have a staff of 20 engineers there's no way these products are being tested properly. Some of the QC is also disheartening. I like my Brew Bucket but probably gunna hold off on ordering more until they take step back and test their products.

I would guess there is one engineer to draw up the designs and he likely works with the manufacturers. From my experience in repairing engineering equipment for almost 20 years I have seen this scenario many many times. Its a smaller company. The person drawing up the product doesnt even have to be a licensed engineer really. The manufacturer that making the MT in china may not be the same one they use for their other products and they may just be learning of these quality limitations along side you guys as the pallets come in.. I would probably make the same choice to ship them and deal with the complaints from those that notice if I were in thier shoes...Otherwise they would have to refund everyone and not ship including those that would feel the issues with theirs are mainly cosmetic and not important.

They are likely working with the manufacturer to resolve the issues as well. SS does have good support and until now there products have been very well received by customers.

Keep in mind there are more than a few brands of these around the world... Like the bru gear conicals its very likely that some of these products come from the same factorys. The ss MT is made of 304 stainless and so far the rest Ive seen are made of 201 or not advertised.

I do think this one is a great deal for being 15 gallon... $303 shipped is a hell of a deal compared to the others on the market..

http://www.ebay.com/itm/Stainless-S...442923?hash=item23559153eb:g:XxAAAOSwT6pVtieY

Paedagogus

Member

- Joined

- Dec 1, 2015

- Messages

- 6

- Reaction score

- 1

Just an update on my situation. I contacted their support and they were very responsive (as they have always been) and apologetic. I was given the option to return the unit for a replacement, and while its not ideal I think it was the best option.

For those of you who have the 20gal mash tun, I suggest looking at the manometer ports and the silicone connectors. I did a leak test and discovered that one of the connectors had a leak. The manometer piping coming out of the mash tun is "non-standard" (ie not a 1/2"npt or similar) so if one of the connectors were to fail during a brew day, it could get messy.

All in all, I think this is a very good product backed up by great customer support. I just wish it was a bit more refined before it was released.

For those of you who have the 20gal mash tun, I suggest looking at the manometer ports and the silicone connectors. I did a leak test and discovered that one of the connectors had a leak. The manometer piping coming out of the mash tun is "non-standard" (ie not a 1/2"npt or similar) so if one of the connectors were to fail during a brew day, it could get messy.

All in all, I think this is a very good product backed up by great customer support. I just wish it was a bit more refined before it was released.

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

ccfoo242

Well-Known Member

Thanks for the info. I was wondering how those were connected.

ccfoo242

Well-Known Member

Got my replacement today. Ever so slight angle still but it's fine. And yeah the false bottom has a bend to it but once installed with the rubber gasket this goes away. Just a bit flexible.

helibrewer

Well-Known Member

Got mine yesterday, plan on brewing tomorrow (Monday). Also got the heater and tested evything today.....no leaks  I will try to take some pictures.....doing a 12 gal batch of Kolsch.

I will try to take some pictures.....doing a 12 gal batch of Kolsch.

helibrewer

Well-Known Member

Did a 12 gal batch of Kolsch. Was not impressed with the heater add-on. My strike water was preheated to 160F through the night using a 1000W heat stick on a controller so the MT was certainly pre-heated. Lost about 20 degrees during dough-in which really surprised me.....also, the heater unit could not maintain my strike temp of 160.

I will be using my RIMs tube, and I did start using it about 10 minutes into the mash since the dough in dropped the temp so much.

EDIT: Things I do like: Construction, geometry, manometer, easy to clean, no dead space

Things I don't like: Add-on temp unit pigtail too short, add-on heater too weak, recirc port needs bushings to adequately tighten, no "on-off" for digital thermometer

Overall all I like it better than my Igloo and am glad I have it.

I will be using my RIMs tube, and I did start using it about 10 minutes into the mash since the dough in dropped the temp so much.

EDIT: Things I do like: Construction, geometry, manometer, easy to clean, no dead space

Things I don't like: Add-on temp unit pigtail too short, add-on heater too weak, recirc port needs bushings to adequately tighten, no "on-off" for digital thermometer

Overall all I like it better than my Igloo and am glad I have it.

Last edited:

Did a 12 gal batch of Kolsch. Was not impressed with the heater add-on. My strike water was preheated to 160F through the night using a 1000W heat stick on a controller so the MT was certainly pre-heated. Lost about 20 degrees during dough-in which really surprised me.....also, the heater unit could not maintain my strike temp of 160.

I will be using my RIMs tube, and I did start using it about 10 minutes into the mash since the dough in dropped the temp so much.

EDIT: Things I do like: Construction, geometry, manometer, easy to clean, no dead space

Things I don't like: Add-on temp unit pigtail too short, add-on heater too weak, recirc port needs bushings to adequately tighten, no "on-off" for digital thermometer

Overall all I like it better than my Igloo and am glad I have it.

Thanks for reporting back. I agree with you on all fronts. My experience with the heater was the same. I've tried it several times now and it simply cannot maintain temperatures in this thing. I believe I mashed in at 166 to hit a mash temp of 148 so I had similar heat loss on the dough-in. To date, I've been losing 3 -4 degrees over an hour even with the heater. SS Brew Tech support is pretty insistent that their testing shows otherwise and that they are consistently able to hold temps within a degree. My experience just doesn't support that though. Looks like I'll need to move to a RIMS or HERMS to get more consistent temps.

augiedoggy

Well-Known Member

That kinda defeats the whole purpose of an insulated mash tun?. Looks like I'll need to move to a RIMS or HERMS to get more consistent temps.

Did a 12 gal batch of Kolsch. Was not impressed with the heater add-on. My strike water was preheated to 160F through the night using a 1000W heat stick on a controller so the MT was certainly pre-heated. Lost about 20 degrees during dough-in which really surprised me.....also, the heater unit could not maintain my strike temp of 160.

I will be using my RIMs tube, and I did start using it about 10 minutes into the mash since the dough in dropped the temp so much.

EDIT: Things I do like: Construction, geometry, manometer, easy to clean, no dead space

Things I don't like: Add-on temp unit pigtail too short, add-on heater too weak, recirc port needs bushings to adequately tighten, no "on-off" for digital thermometer

Overall all I like it better than my Igloo and am glad I have it.

Thanks for reporting back. I agree with you on all fronts. My experience with the heater was the same. I've tried it several times now and it simply cannot maintain temperatures in this thing. I believe I mashed in at 166 to hit a mash temp of 148 so I had similar heat loss on the dough-in. To date, I've been losing 3 -4 degrees over an hour even with the heater. SS Brew Tech support is pretty insistent that their testing shows otherwise and that they are consistently able to hold temps within a degree. My experience just doesn't support that though. Looks like I'll need to move to a RIMS or HERMS to get more consistent temps.

I guess I'm confused. You drop close to $650 on a item that is suppose to hold temps (+/-1F?) and it drops 5F over an hour even with the heat? I also read you need to pre-heat the vessel too!? Now you're going to drop more money on a RIMS or HERMS, which aren't cheap, because the unit doesn't work as advertised? I'd return it instantly! If nothing else why not exchange it for a standard 20gal kettle and save like $300?

Am I missing something?

geoffey

Well-Known Member

I guess I'm confused. You drop close to $650 on a item that is suppose to hold temps (+/-1F?) and it drops 5F over an hour even with the heat? I also read you need to pre-heat the vessel too!? Now you're going to drop more money on a RIMS or HERMS, which aren't cheap, because the unit doesn't work as advertised? I'd return it instantly! If nothing else why not exchange it for a standard 20gal kettle and save like $300?

Am I missing something?

Totally agree with this. If the damn thing doesn't work close to advertised then you should get a refund. But I gotta say, it's really hard to believe and insulated mash tun like this can't hold temps better than what you're experiencing. Especially with that heater. There has to be something else to this story we aren't getting.

augiedoggy

Well-Known Member

Maybe the stainless is somehow conducting the heat out of the mash instead of acting as an insulator? seems plastic does have One advantage... I use a 16 gallon bayou kettle now for a mashtun but even when I used my igloo beverage cooler alone I did not see those kind of drops... I wonder if the insulation material is to blame too..

Are you guys brewing out in the freezing cold or something? I guess I shouldnt assume that nice equipment like this would only be found in an indoor brewing setup.

Are you guys brewing out in the freezing cold or something? I guess I shouldnt assume that nice equipment like this would only be found in an indoor brewing setup.

Well, at this point, I am just trying to determine if there is something in my process that I am doing wrong or can change to better hold temperatures. My basic process has been to heat my mash water 20 degrees over my target strike-in temperature, transfer it over to the room temperature mash tun (60 degrees) let it fall naturally to strike temp (thus preheating the tun) and then dough-in (60 degree grain). I brew in my basement and the temperature in the room (this time of year) is usually right around 60 degrees. I emailed SS Brew Tech support again to see if they have any other advice. They suggested the following:

A few additional tips that might help you reduce heat loss over 60 minutes.

1. If you are not using the upper recirculation port, that is a point where heat escapes, swap it out for the silicone boot or plug the whole with aluminum foil until you ultimately decide to use it for recirculating your mash.

2. Thoroughly inspect your lid seal to make sure that no heat is escaping there. The silicone gasket should be completely resting on the rim of the mash tun creating an air-tight seal. We see this with users all the time, typically there is a sweet spot for mating the lid to the tun, run your hand along the upper rim to insure that you don't feel heat escaping. If you do, rotate the lid 45 degrees and recheck it.

3. Remove the lid as little as possible. Removing it allows all the residual heat from the grist to escape, then even more heat is pulled away from the grain bed to re-stabilize the temp inside the tun. When we run our tests, we never remove the lid, that is how we are able to achieve heat loss statistics of around 1 degree per hour. It may sound trivial, but this is one of the biggest reasons users don't hit their numbers; they are always unnecessarily stirring and checking their mash temp. That is precisely why we put an LCD temp gauge and thermowell on the outside, so you don't need to remove the lid.

4. Thin out your mash, if you are mashing thick at 1.2 qts/lb, thin it out to 1.5 qts a lb. The specific heat of water is very high, and a larger water volume helps to stabilize temps.

Believe it or not, just these four factors should be good for another 1-2 degrees over 60 mins. Give them a try!

A few additional tips that might help you reduce heat loss over 60 minutes.

1. If you are not using the upper recirculation port, that is a point where heat escapes, swap it out for the silicone boot or plug the whole with aluminum foil until you ultimately decide to use it for recirculating your mash.

2. Thoroughly inspect your lid seal to make sure that no heat is escaping there. The silicone gasket should be completely resting on the rim of the mash tun creating an air-tight seal. We see this with users all the time, typically there is a sweet spot for mating the lid to the tun, run your hand along the upper rim to insure that you don't feel heat escaping. If you do, rotate the lid 45 degrees and recheck it.

3. Remove the lid as little as possible. Removing it allows all the residual heat from the grist to escape, then even more heat is pulled away from the grain bed to re-stabilize the temp inside the tun. When we run our tests, we never remove the lid, that is how we are able to achieve heat loss statistics of around 1 degree per hour. It may sound trivial, but this is one of the biggest reasons users don't hit their numbers; they are always unnecessarily stirring and checking their mash temp. That is precisely why we put an LCD temp gauge and thermowell on the outside, so you don't need to remove the lid.

4. Thin out your mash, if you are mashing thick at 1.2 qts/lb, thin it out to 1.5 qts a lb. The specific heat of water is very high, and a larger water volume helps to stabilize temps.

Believe it or not, just these four factors should be good for another 1-2 degrees over 60 mins. Give them a try!

geoffey

Well-Known Member

How many more degrees higher are you mashing in than your targeted mash temp? For example, if you target a 155 temp for your mash, and you are transferring your strike water over at 175, you probably lose 10-12 degrees in the transfer and as the tun heat up. You're going to lose an additional 5-10 degrees at mash in due to the temp of the grain. So you might need to mash in at 165 to hit 155. And if your water temp has lost more than 10 degrees already after transferring to the MT then you're already behind.

augiedoggy

Well-Known Member

I heat my water to 163 degrees before transferring it to my uninsulated MT before doughing in once I've added the grain I'm usually around 150 and then I start my rim recirculation so with 165 degree water should get him around 152 degrees at room temp environment..How many more degrees higher are you mashing in than your targeted mash temp? For example, if you target a 155 temp for your mash, and you are transferring your strike water over at 175, you probably lose 10-12 degrees in the transfer and as the tun heat up. You're going to lose an additional 5-10 degrees at mash in due to the temp of the grain. So you might need to mash in at 165 to hit 155. And if your water temp has lost more than 10 degrees already after transferring to the MT then you're already behind.

augiedoggy

Well-Known Member

Are you saying your not recirculating? I would think that necessary with the heater or your gonna have a concentrated area by your heater that up to temp and uneven lower temps everywhere else.. Where is the temp probe for the heater? If its near your heater that's likely what's going in (if your not recirculating)Well, at this point, I am just trying to determine if there is something in my process that I am doing wrong or can change to better hold temperatures. My basic process has been to heat my mash water 20 degrees over my target strike-in temperature, transfer it over to the room temperature mash tun (60 degrees) let it fall naturally to strike temp (thus preheating the tun) and then dough-in (60 degree grain). I brew in my basement and the temperature in the room (this time of year) is usually right around 60 degrees. I emailed SS Brew Tech support again to see if they have any other advice. They suggested the following:

A few additional tips that might help you reduce heat loss over 60 minutes.

1. If you are not using the upper recirculation port, that is a point where heat escapes, swap it out for the silicone boot or plug the whole with aluminum foil until you ultimately decide to use it for recirculating your mash.

2. Thoroughly inspect your lid seal to make sure that no heat is escaping there. The silicone gasket should be completely resting on the rim of the mash tun creating an air-tight seal. We see this with users all the time, typically there is a sweet spot for mating the lid to the tun, run your hand along the upper rim to insure that you don't feel heat escaping. If you do, rotate the lid 45 degrees and recheck it.

3. Remove the lid as little as possible. Removing it allows all the residual heat from the grist to escape, then even more heat is pulled away from the grain bed to re-stabilize the temp inside the tun. When we run our tests, we never remove the lid, that is how we are able to achieve heat loss statistics of around 1 degree per hour. It may sound trivial, but this is one of the biggest reasons users don't hit their numbers; they are always unnecessarily stirring and checking their mash temp. That is precisely why we put an LCD temp gauge and thermowell on the outside, so you don't need to remove the lid.

4. Thin out your mash, if you are mashing thick at 1.2 qts/lb, thin it out to 1.5 qts a lb. The specific heat of water is very high, and a larger water volume helps to stabilize temps.

Believe it or not, just these four factors should be good for another 1-2 degrees over 60 mins. Give them a try!

helibrewer

Well-Known Member

The silicone heating pad is on the bottom of the MT, the temp sensor is in the thermowell, 6-7" above the bottom.

helibrewer

Well-Known Member

Brew in the garage, about 60F......

How many more degrees higher are you mashing in than your targeted mash temp? For example, if you target a 155 temp for your mash, and you are transferring your strike water over at 175, you probably lose 10-12 degrees in the transfer and as the tun heat up. You're going to lose an additional 5-10 degrees at mash in due to the temp of the grain. So you might need to mash in at 165 to hit 155. And if your water temp has lost more than 10 degrees already after transferring to the MT then you're already behind.

I use Beersmith to help me calculate this based on mash tun temperature and grain temperature. Typically, I will need to dough in about 12-14 degrees over my desired mash temperature. So if I'm trying to hit 148 for example, I would transfer 175 degree water over, let it sit until it drops to about 160 or 162 then mash in to hit 148.

Are you saying your not recirculating? I would think that necessary with the heater or your gonna have a concentrated area by your heater that up to temp and uneven lower temps everywhere else.. Where is the temp probe for the heater? If its near your heater that's likely what's going in (if your not recirculating)

I have not been recirculating throughout the mash. I only recirculate at the end of the mash for about 20 minutes to clarify the wort. If I remember right, I beleive my temperature bumped up a degree when I started recirculating, but then lost a couple more degrees by the end of the 20 minutes. The heating pad is only 60 watts, so it does not throw off an incredible amount of heat.

helibrewer

Well-Known Member

My ideal MT would be a dual wall SS without insulation....so I could run hot water through the "jacket" for temp control.....probably only need lower 1/3 jacketed

augiedoggy

Well-Known Member

I use Beersmith to help me calculate this based on mash tun temperature and grain temperature. Typically, I will need to dough in about 12-14 degrees over my desired mash temperature. So if I'm trying to hit 148 for example, I would transfer 175 degree water over, let it sit until it drops to about 160 or 162 then mash in to hit 148.

I have not been recirculating throughout the mash. I only recirculate at the end of the mash for about 20 minutes to clarify the wort. If I remember right, I beleive my temperature bumped up a degree when I started recirculating, but then lost a couple more degrees by the end of the 20 minutes. The heating pad is only 60 watts, so it does not throw off an incredible amount of heat.

Thats your issue... you need to recirculate of the temps will never even out ... your temps are jumping around because things are all unven and it takes a while to even out the layers of temps in your mash..

helibrewer

Well-Known Member

Here are the issues with recirculating:

1) SS Brewing says you don't need to, with or without their heater

2) You can't recirc without an external heat source, the 60 watt MT heater cannot support the heat loss of recirculating.

So unless you are going to use a RIM's or HERMs system, recirculating only accelerates heat loss. I have always used a RIM's and will just continue to with this MT....I may even add a mash mixer.

1) SS Brewing says you don't need to, with or without their heater

2) You can't recirc without an external heat source, the 60 watt MT heater cannot support the heat loss of recirculating.

So unless you are going to use a RIM's or HERMs system, recirculating only accelerates heat loss. I have always used a RIM's and will just continue to with this MT....I may even add a mash mixer.

geoffey

Well-Known Member

Here are the issues with recirculating:

1) SS Brewing says you don't need to, with or without their heater

2) You can't recirc without an external heat source, the 60 watt MT heater cannot support the heat loss of recirculating.

So unless you are going to use a RIM's or HERMs system, recirculating only accelerates heat loss. I have always used a RIM's and will just continue to with this MT....I may even add a mash mixer.

SSBrewtech FAQ says not to recirc with this mashtun unless you do herms or rims because as you say, that heat pad cannot sustain the heat loss of recirculating.

It sounds to me like the MT in question here is missing the insulation or something.

ccfoo242

Well-Known Member

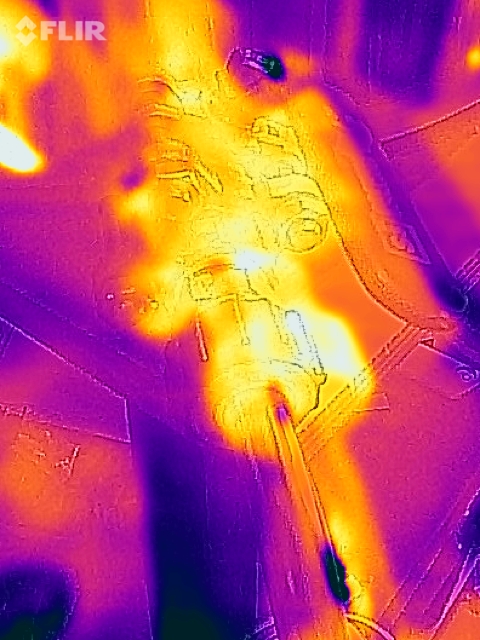

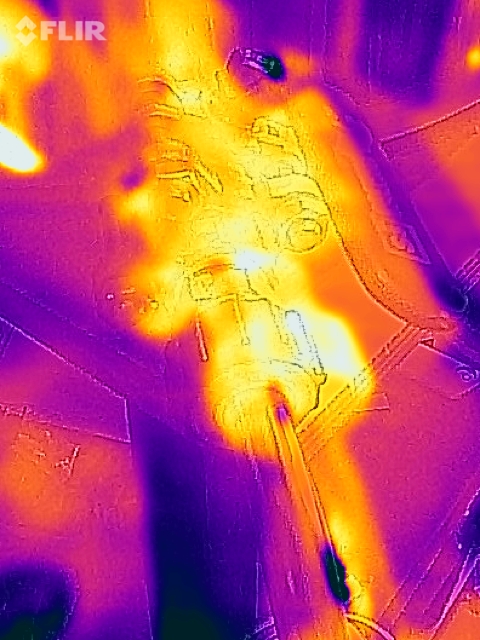

I heated up some water to use for cleaning the mash tun and cycled it through. I took some photos with a friend's Flir camera to see where heat losses were:

Here you can see the SS Brewtech mash ton on top. Blichmann 15 gallon pot with boil coil heating the water on the bottom. Heat losses are the silicone tubing (it's the thick walled kind), ball valve, and a little bit where the thermometer is. Lots of heat coming out of the bottom pot, I didn't have a lid.

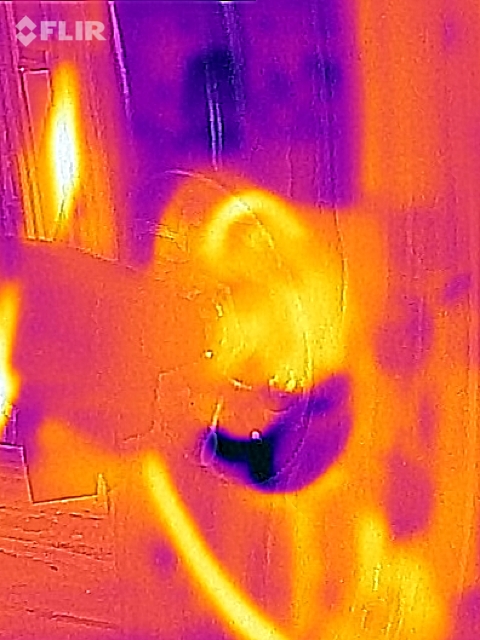

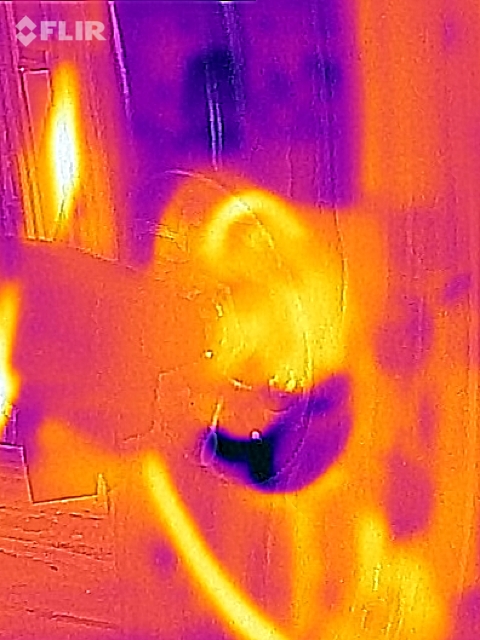

Close up of the ball valve:

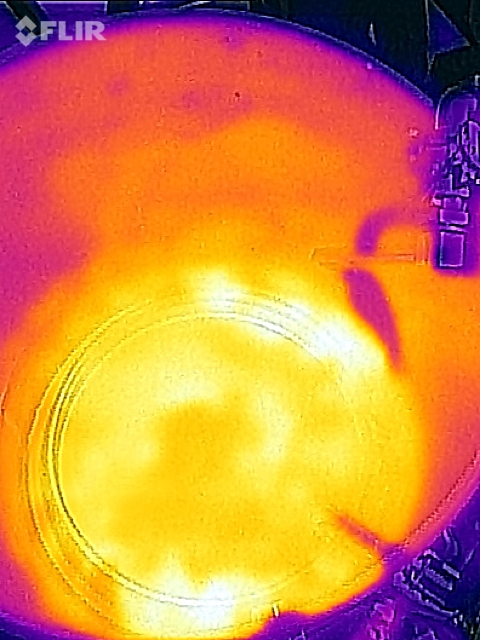

The hard part about getting a thermal image of the mash tun is that it reflects heat. I walked all around it and couldn't find any hot patches. Just reflections of hotter objects in the room. Even around the lid there were no visible hot spots:

Close up of the thermometer area. The thinnest parts leak some heat:

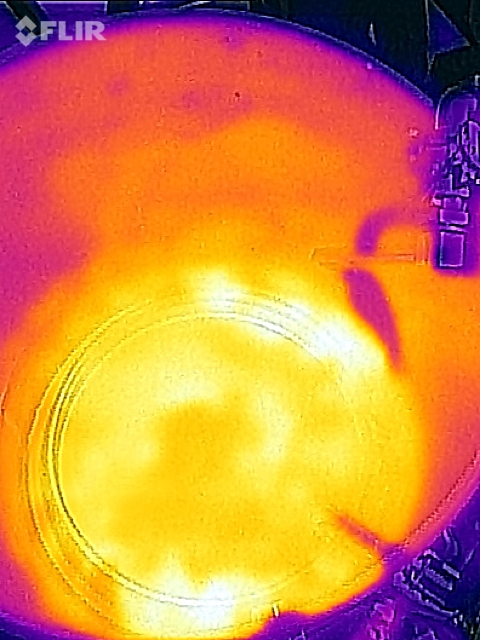

Looking down into Mt. Doom, Frodo doesn't want to let go of the Ring just yet:

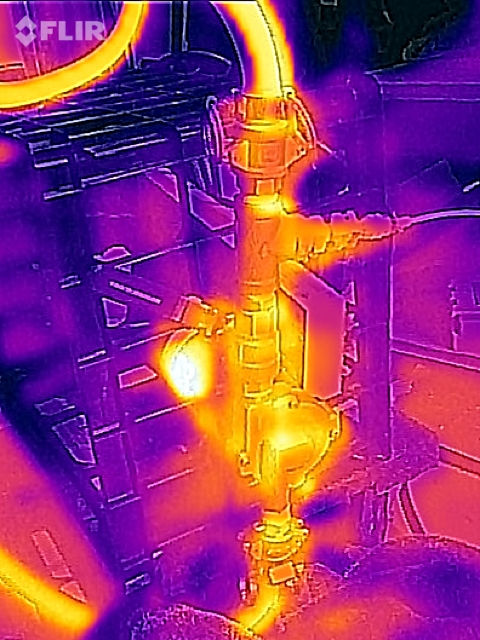

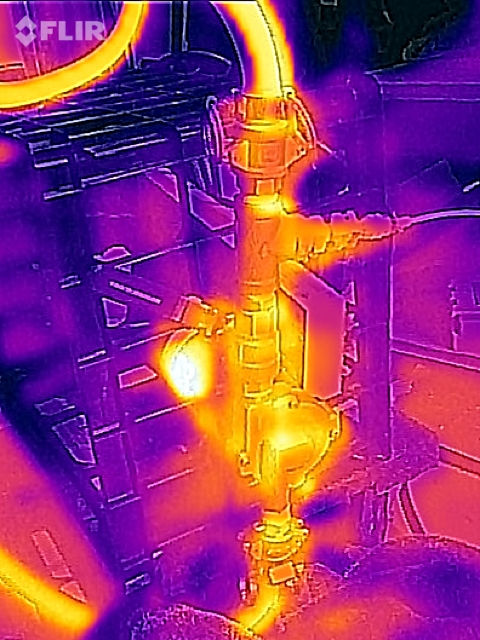

Finally, the pump loses heat:

I still haven't brewed with the dang thing. I think once I get my brew stand built and have a more permanent setup I'll probably insulate the tubing.

Here you can see the SS Brewtech mash ton on top. Blichmann 15 gallon pot with boil coil heating the water on the bottom. Heat losses are the silicone tubing (it's the thick walled kind), ball valve, and a little bit where the thermometer is. Lots of heat coming out of the bottom pot, I didn't have a lid.

Close up of the ball valve:

The hard part about getting a thermal image of the mash tun is that it reflects heat. I walked all around it and couldn't find any hot patches. Just reflections of hotter objects in the room. Even around the lid there were no visible hot spots:

Close up of the thermometer area. The thinnest parts leak some heat:

Looking down into Mt. Doom, Frodo doesn't want to let go of the Ring just yet:

Finally, the pump loses heat:

I still haven't brewed with the dang thing. I think once I get my brew stand built and have a more permanent setup I'll probably insulate the tubing.

augiedoggy

Well-Known Member

SSBrewtech FAQ says not to recirc with this mashtun unless you do herms or rims because as you say, that heat pad cannot sustain the heat loss of recirculating.

It sounds to me like the MT in question here is missing the insulation or something.

I dont see how the grain stays at even temp with the heating pad at the bottom and no recirculation myself... You would need to constantly stir which would also cause huge temp losses. Otherwise you would have a hotspot down by the heater. Ask people that direct heat their mash tuns, this is why some put them in the oven to maintain temps.

Using a rims or herms makes the whole insulation bit pointless as was discussed in the smaller infussion thread.. Its just more costly more work to clean, redundant and not practical.

Not trying to be negative here but dont you think after paying so much for the insulated kettle and then all the work insulating hoses and such it would have honestly been better to just us a rims or herms? and by that same token if you use a rims or herms there will be no advantage of the insulated mash tun so why spend extra for it and deal this the additional bulk and hassle cleaning it?

In any case the stainless has to be working as a heatsink or the insulation itself may be inferior since from my experience with a regular beverage cooler it holds temps better with no heater or recirculation, and In my opinion SS should have done some engineering to make it work at least as good as a cooler...

Functionality shouldnt have to take a back seat to the cosmetics of stainless.

madscientist451

Well-Known Member

Interesting thread and good to see what others are brewing with. After following this and similar threads for years, and sampling beers made with expensive rigs at my brew club, I can't say for sure that a complicated brewing set up really makes better beer. But to each his/her own, Its fun to get new stuff and for some, the challenge of getting everything working right is part if the fun.

Guess I'm just simply a cheapskate, but spending $650 for a mash tun and then having to fuss with it to get it to work right doesn't seem like a good value.

I'm sticking with my cheapo cooler that holds the mash temp within a few degrees while the mash is doing its thing, doesn't recirculate, doesn't need heat and the beer comes out consistently better than the "craft beer" made in million dollar breweries.

Guess I'm just simply a cheapskate, but spending $650 for a mash tun and then having to fuss with it to get it to work right doesn't seem like a good value.

I'm sticking with my cheapo cooler that holds the mash temp within a few degrees while the mash is doing its thing, doesn't recirculate, doesn't need heat and the beer comes out consistently better than the "craft beer" made in million dollar breweries.

Similar threads

- Replies

- 0

- Views

- 251

- Replies

- 2

- Views

- 298

- Replies

- 0

- Views

- 675

- Replies

- 0

- Views

- 351

- Replies

- 22

- Views

- 4K

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)