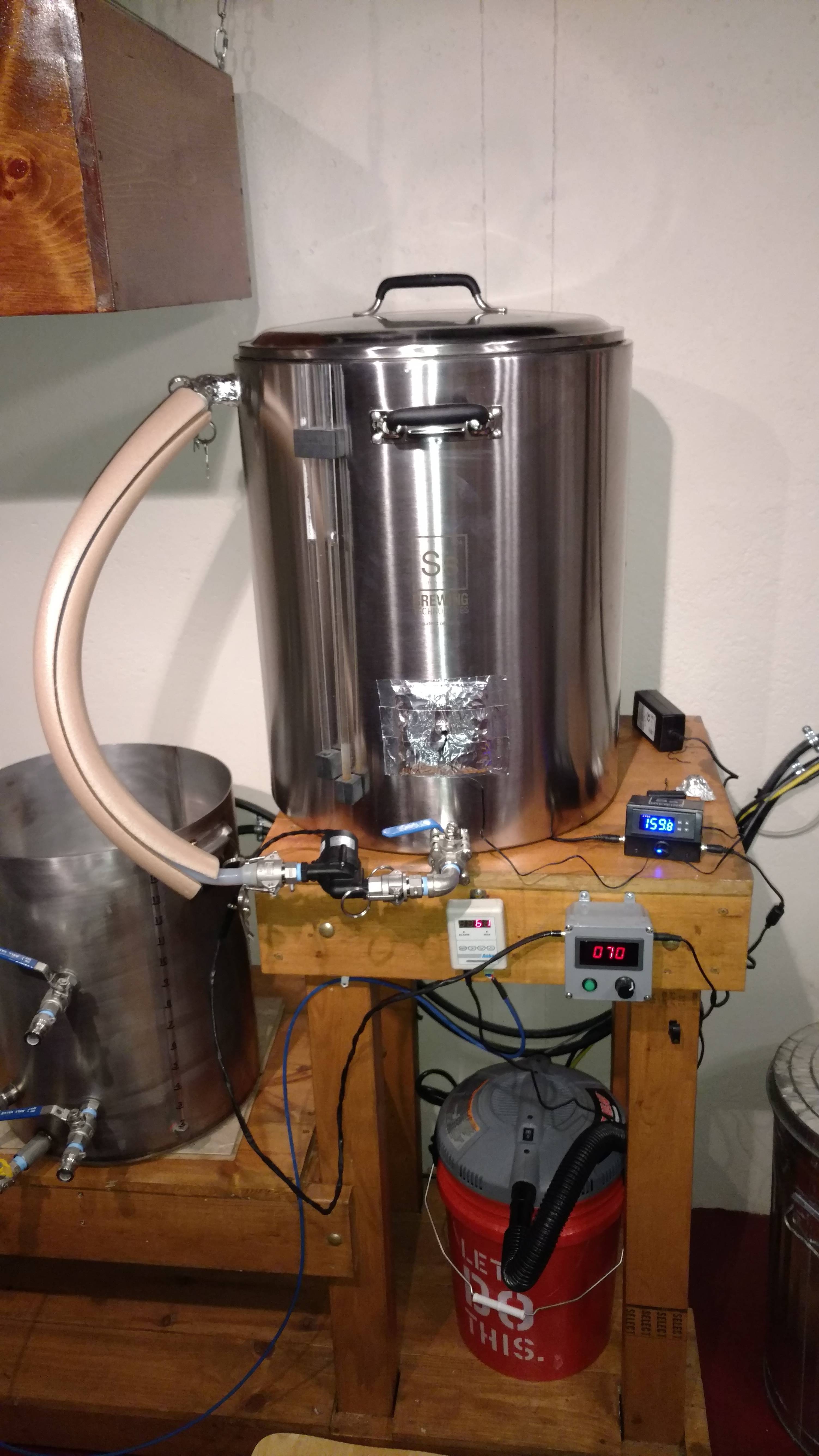

Ive had the 10g Ss Infussion since January and have made 18 batches with it so far. Hands down its the worst homebrewing purchase Ive made since I started brewing in 2008. Sorry this is so long, but I assume some people will appreciate all these details in deciding whether to buy this expensive equipment.

First, the LCD thermometer that comes with it jumps around much more than Ive seen on other thermometers. And both that and the Temp Control readings seem completely unreliable. I have three handheld thermometers that are calibrated (glass, analog, and digital). At the end of the mash, Id note the temp on the Ss thermometer I was using, take off the lid, and then insert one or some of my thermometers into the mash right next to the tip of the thermowell and take a reading. The LCD thermometer was different by the following degrees F from my calibrated equipment: -0.8, +2.0, +3.5, +3.5, -4.2, +6.1, and -4.9. On the Temp Control unit, I got spreads of +6.2, +8.6, -6.1, -5.3, -5.1, +1.1, -3.8, -4.2, and -5.4F. So a varying spread of 11.0F and 14.7F, respectively.

For the Temp Control unit, their advertising includes: "it can help with fine tuning your strike water temp those last few degrees" and "For a typical strike water volume (approx. 5gals), the heater will increase strike water temps by roughly 5F/hour." I was not experiencing this so I did some tests (all with the lid never removed).

I tested the system out with just water inside my house, at 65F, with the heating unit. The temp was stabilized at 133.5. I turned the heater on. Two and a half hours later the temp was at 136.5. So it rose 3 degrees in two and a half hours. And I was doing this at an even lower temp than a normal single infusion dough-in temp. In another test, after the temp stabilized at 144.5, I let the heater go until it raised the temp 5 degrees. It took six and a half hours.

Their Customer Service said: We test in Southern California at 65-80 degree ambient temps, so your low ambient temps are definitely the crux of the issue in this case. I had already explained that while the brew day problems I had with it were outside (winter in Zone 6b), I did these tests inside at 65F. But I waited until summer and collected some more data. Id start my brew day early so I could let the strike water sit and test out the Temp Control unit while it was in the 70s and 80s outside. On one brew day, I added 160F water at my full strike volume to the MLT to preheat it. After 10 minutes, the Temp Control unit read 154.5F. I wanted it at 156F strike so I plugged in the heating unit. After 48 minutes the temperature dropped to 154.0F.

Next brew day, I added 4.35 gallons of 167F water. At 10 minutes it was stabilized at 161F. I then set the heater to 165F. 95 minutes later the strike water dropped to 159.8F.

Next brew day, I again added 4.35 gallons of 167F water. After 10 minutes it was 162.1. I then set the heater to 167. After 3 hours and 5 minutes, the temperature dropped to 160.8F. (Note that I turned it on dry before adding the water and it did get the bottom hot - a test they previously told me to try that Ive done a couple of times to confirm its working.)

I tend not to use the Temp Control unit during the mash itself because of how unpredictable it is. But on one brew day at 23 minutes into a 90 minute mash, I plugged in the heater. It was 146.3F at 23 minutes (target 149F). At 60 minutes it was 145.7F. At 90 minutes it was 146.6F. So it dropped and then only rose a total of 0.3F over 67 minutes. On the brew day above when I had the heater on for over 3 hours to try and raise my strike water, I left it on through my mash. I lowered the target to 154F. 10 minutes into the mash, it was 150.6. At 60 minutes, it was 156.5. So it finally worked but it overshot by 2.5F.

In sum, I no longer have consistency and repeatability for my mashes. Id like to switch out the thermometer to a more reliable analog thermometer but this requires ⅜ NPT, which even Ss doesnt carry. The only ones Ive found so far are expensive and with lots of S&H. My LHBS couldnt find any in that size through their supplier.

There are lots of other miscellaneous issues. For example, the gasket around the false bottom started fraying after just a few uses. I cut off that fray but now its started fraying again in a few spots. The rubber feet pop off easily (lost one in the yard for a while). You can feel a weak spot in the design where its warm at the indentation around the thermowell (seems like that could have been avoided but Im no engineer). After just 6 months, one of the LCD bars on the Temp Controller is out. And, at the end of running off when it starts sputtering, it often begins to pull through grain into the BK. I didnt have this problem with my cooler MLT and I wonder if its the 5 degree sloped bottom design, which is meant to catch small grain that makes it through the false bottom. When its sputtering at the end, Im guessing it creates enough force to pull many of those bits off. If anyone has thoughts on how to prevent this (other than trying to turn off the ball valve as quickly as possible), please let me know since I dont like lots of grain bits in my BK.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)