Hey all -

Been AWOL while I work on this, and I'm afraid to say I don't believe it's going well at all. It's funny, because I don't recall having this much trouble the last time (20 years ago, lol), unless I was just clueless as to accepting what would be unacceptably weak welds then, and I was just lucky.

You've all been extremely helpful in this thread, and I know especially without pics (I hope to post some), you can't do much more. I am grateful but I'm feeling like I blew it, and given the ease with which FCAW is to dive in and do, I feel like a rube.

I continue to get issues with burnthrough whenever doing a tee joint. I have tried to increase stickout and lower heat, and it's still almost bankable that I hear that "air tube" and sure enough, a hole or many. I'm sure this is wrong, but I've allowed to cool, and tried to just overlay more wire, weaving to get it to fill in. Often, it just makes the hole worse. Dog House, I know you mentioned treating it like a spot weld and I probably shouldn't have been too embarrassed to ask. I've got a lot of tee joints with undercutting and burnthroughs.

Fillets don't have this problem. Despite bringing light down to bear, I still can't see well and often get a start by sticking the wire in the joint, pulling back a measure, bringing helmet down (not at all happy with this HD helmet, but I'm in at this point), and giving it a whirl. Sometimes OK, sometimes it looks like cold lapping on the bottom member, with little inclusion on the upper member, and nowhere near the proper looking bead I had even on day 1. I don't get why I'm having such an issue with burnthrough on the Tee Joint, and having an issue - I think - with a good, strong bead on the fillets. I even have resorted to minor circling to try and draw the puddle up more on the vertical member. Basically, I still can't see. I won't do it at this point, one because it feels like the kind of thing of "it worked forever, without needing it," but Jody on the website strongly urges getting an auto-darkening helmet from Northern Tools, for currently $60. "Ensures good starts," and right now, it feels like this noob could use all the help he can get. Anyway, worse welding than on Day 1, and I can't figure it out.

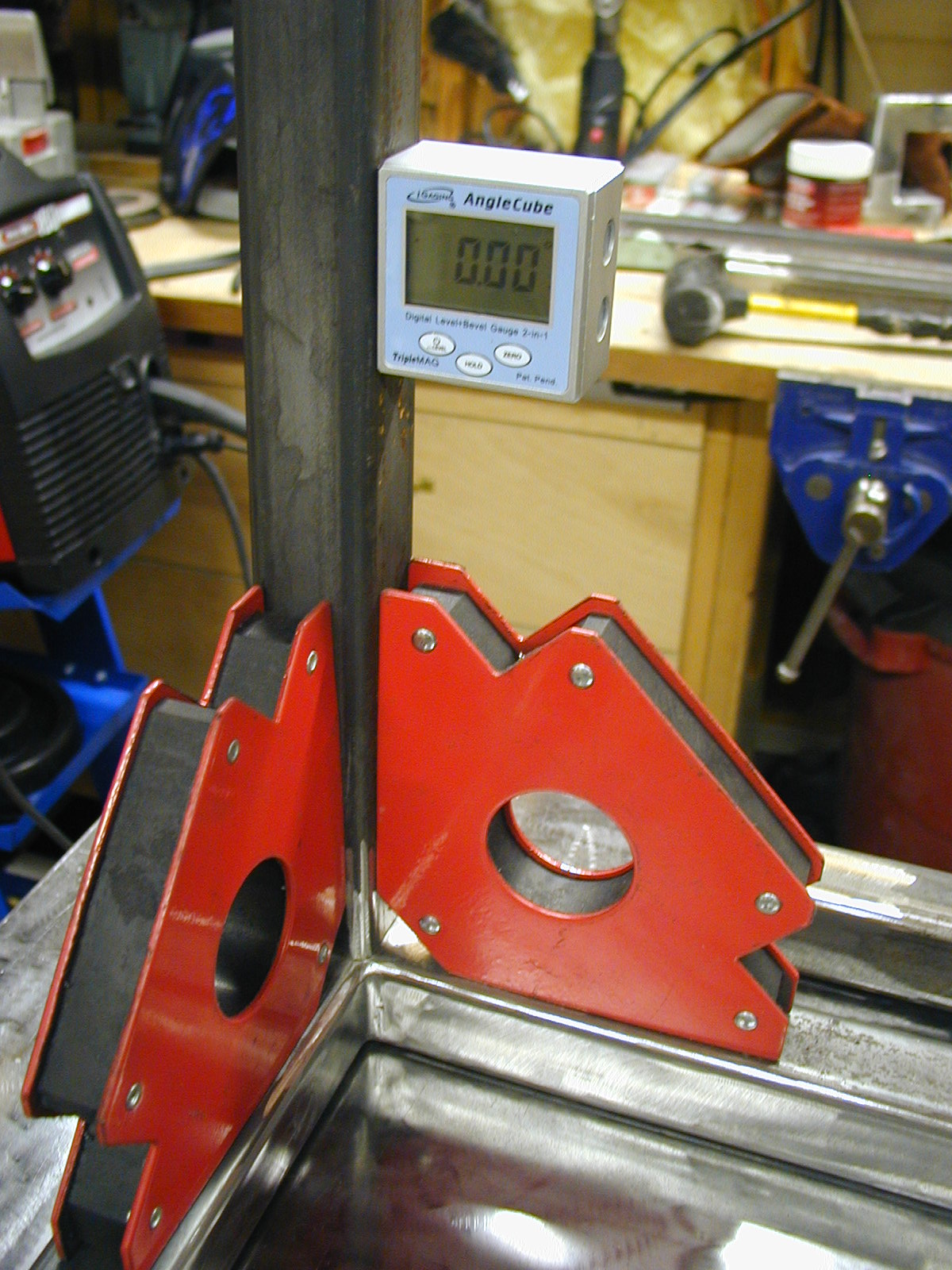

Finally, though I've tried to tack diligently and watch for heat distortion effects, whatever they're called, I've...blown that one, too. Horizontal vessel supports, struts, for instance, that "rest" on the rear horizontal member, are off by as much as, 3/8" or so I'd say, so that rear support is useless in terms of supporting vessels. I'd thought to try and clamp the crap out of everything when I finish all main parts, assembling them together (meaning, forcing any misaligned parts by mere clamping and welding, if possible) but then I'd imagine all I have are - what would it be called, internal stresses? - so that's a further weakening.

Anyway, pretty frustrated with myself because I honestly feel like my rig of 20 years ago was a better rig, with 1 x 1, and I knew literally nothing then. I don't get why this one blows as much as it does, unless it's some combination of my body (pretty messed up by end of day - pain:tension:bad welding?), vision less than it once was....but I know that's probably b.s., since I know alot of you are pros who continue to weld, though I might be many years your junior.

Sounds like excuses reading it, but just half tempted to keep this all for scrap, buy another 3 x 24', and try again, as an expensive lesson. The other half says forget it, pay a welder, and learn for next time via a course (found out our local tech has definitely changed policy, and all classes are open to outside students not in the pro track program). I'm not sure this rig is safe, though at 20 gallons it's little more than my previous 1/2 bbl keggle system.

Thanks for reading a rant, I guess I'd call it, and for all your generous help, guys.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)