kpr121

Well-Known Member

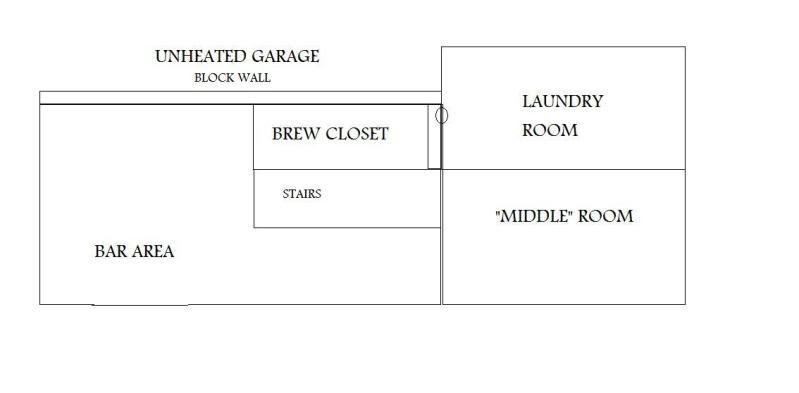

My newest project (seems like I have a lot of these since I started brewing  ) is to turn the closet in my bar downstairs into a fermentation / cellaring closet.

) is to turn the closet in my bar downstairs into a fermentation / cellaring closet.

The plan is to use a 5000 BTU ac unit to cool an approximately 3 x 8 x 7 area inside the closet. I'll be insulating it with R-13 batting and probably 2" polystyrene foam board.

Heres a pic of the closet from behind the bar (old picture, my camera needs charged).

The left wall is a semi exterior wall, it leads to an unheated garage. The right wall is the adjacent to the stairs, and the back wall leads to the other room in the basement:

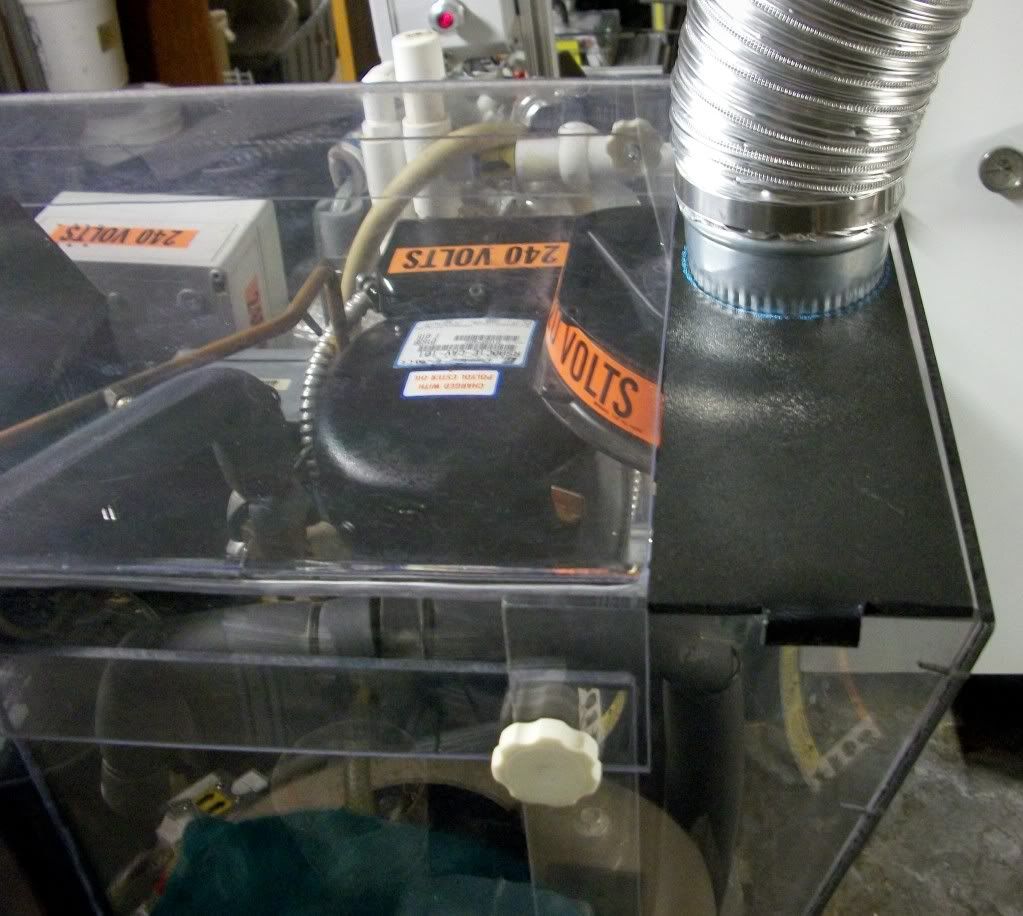

I'll be trying to update this thread with pictures and details as the project progresses. As of now I just have the AC mounted in the rear of the closet, and thats about all, nothing exciting.

Are there any real issues with using this area for both fermentation and long term beer storage? I would mostly only be fermenting ales, lagers only if after testing I can get the temps down that low. I would also like to maybe store some wine in this closet as well. If I go the lager route I may have to create a separate chamber to keep the overall temps consistent.

The plan is to use a 5000 BTU ac unit to cool an approximately 3 x 8 x 7 area inside the closet. I'll be insulating it with R-13 batting and probably 2" polystyrene foam board.

Heres a pic of the closet from behind the bar (old picture, my camera needs charged).

The left wall is a semi exterior wall, it leads to an unheated garage. The right wall is the adjacent to the stairs, and the back wall leads to the other room in the basement:

I'll be trying to update this thread with pictures and details as the project progresses. As of now I just have the AC mounted in the rear of the closet, and thats about all, nothing exciting.

Are there any real issues with using this area for both fermentation and long term beer storage? I would mostly only be fermenting ales, lagers only if after testing I can get the temps down that low. I would also like to maybe store some wine in this closet as well. If I go the lager route I may have to create a separate chamber to keep the overall temps consistent.

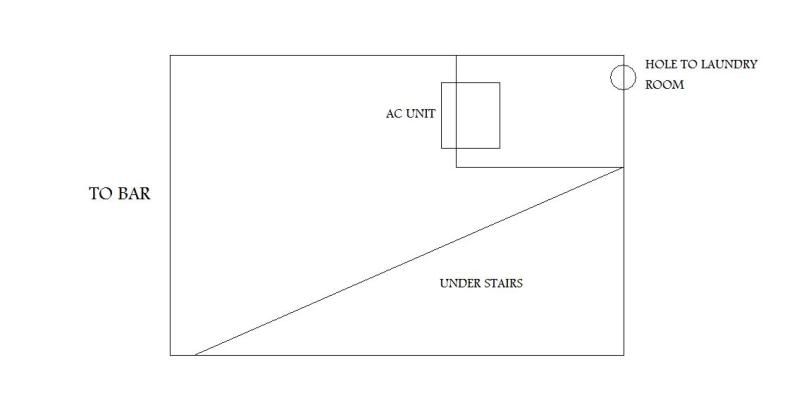

If you look at the picture you can imagine the entire area behind the AC blocked off from the rest of the closet (well insulated also), and that area being ventilated through the hole in the back of the wall to the laundry room, or ducted with insulation down to the right under the stairs.

If you look at the picture you can imagine the entire area behind the AC blocked off from the rest of the closet (well insulated also), and that area being ventilated through the hole in the back of the wall to the laundry room, or ducted with insulation down to the right under the stairs.