Largus1776

Active Member

- Joined

- Jan 28, 2014

- Messages

- 34

- Reaction score

- 2

Brew In A Bag: BIAB with HERMS via Outboard RIMS-Tube

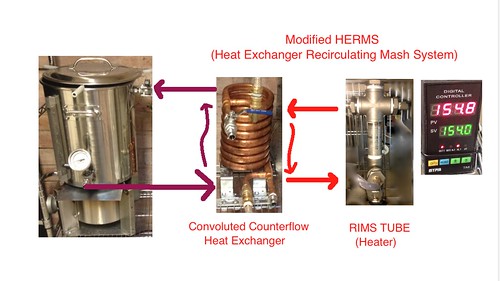

Pictured is an alternative mash recirculation system for Brew In A Bag. Temperature control of the mash employs a modified HERMS approach comprised of an outboard RIMS-tube heater that maintains the temperature of the mash recirculation via a Convoluted Counterflow Coil Heat Exchanger. A feature of this system is that the RIMS-tube heater-element is not incorporated into the flow of the wort.

The brew stand has a 72,000BTU output burner that quickly heats the water to temperature for strike and boil. However, the same high-energy output makes it a bit difficult to subsequently precisely control the mash temperature on intermittent low heat, and also requires minding the pot. An alternative commercially available temperature controller, with automatic intermittent propane ignition, seems not the optimal tool to be left unattended.

Thus, this modified application of HERMS for mash temperature control was undertaken to avoid the potential disadvantages of the RIMS-tube heating element directly contacting the wort. This implementation has the similar advantages of indirect heat of that of a double or jacketed boiler. Other disadvantages of an in-line RIMS-tube is that it adds extra equipment in the wort circulation and requires cleaning: not in best keeping with BIAB simple philosophy. Whereas this implementation adds no additional equipment in the wort path, and does not add to cleaning.

Other design criteria included that the home brewery location in a temperate climate allows for brewing in the glorious outdoors, so this rig uses 120V for (USA mains) plug and play readiness. (Although this system can operate at 240V/30Amp, that would require being tethered to an installed dedicated circuit in the brewery). As implemented: the 4500 Watt 240 Volt heating element run at 120 Volts produces 1125 Watts, sufficient to maintain mash temperature, and draws 9.3 Amps. Thus the 120V RIMS tube circuit, together with the pumps and electronic controllers (PID), runs on a single 120V 15 Amp mains circuit.

The ability to quickly heat water to strike temperature or boil, subsequently automatically maintain precision temperatures during the mash, no stirring, and only one kettle to clean; this makes for a expeditious and enjoyable brew day with consistent results.

More pictures are here:

http://www.flickr.com/photos/115125929@N08/sets/72157640487505774/

And a video tour here:

[ame]http://youtu.be/KrCy3reG82o[/ame]

or here:

www.youtube.com/channel/UCeUfIH0seYepqQ6Hgvp1qrg/videos

This forum and others are very helpful in providing needed information on re-entry into home brewing, building the brew stand, and initiating full grain mashes. There are previous descriptions by other brewers where the HLT is directed via a CCF Chiller to maintain mash temperature. These concepts are extended and adapted into this single vessel BIAB design, in which there is no HLT. The earliest reference was possibly by Baltobrewer in 2004, (and then blogging on papyrus, the first description of moving water through a copper coil was by Archimedes ;-). So some of these concepts have been around for a long time.

Thanks!

TAGS: BIAB HERMS RIMS, Brew In A Bag, Heat Exchange Recirculation Mash System, Recirculation Infusion Mash System, RIMS tube, Convoluted Counterflow Chiller, Wort, Brew Stand, Brew Sculpture, Brew Automation, Mash Temperature Control, PID, Home Brew, Home Brewery Setup, Single Kettle Vessel, Electric Brewery, Propane, Gas Fired, Beer, Largus1776

Pictured is an alternative mash recirculation system for Brew In A Bag. Temperature control of the mash employs a modified HERMS approach comprised of an outboard RIMS-tube heater that maintains the temperature of the mash recirculation via a Convoluted Counterflow Coil Heat Exchanger. A feature of this system is that the RIMS-tube heater-element is not incorporated into the flow of the wort.

The brew stand has a 72,000BTU output burner that quickly heats the water to temperature for strike and boil. However, the same high-energy output makes it a bit difficult to subsequently precisely control the mash temperature on intermittent low heat, and also requires minding the pot. An alternative commercially available temperature controller, with automatic intermittent propane ignition, seems not the optimal tool to be left unattended.

Thus, this modified application of HERMS for mash temperature control was undertaken to avoid the potential disadvantages of the RIMS-tube heating element directly contacting the wort. This implementation has the similar advantages of indirect heat of that of a double or jacketed boiler. Other disadvantages of an in-line RIMS-tube is that it adds extra equipment in the wort circulation and requires cleaning: not in best keeping with BIAB simple philosophy. Whereas this implementation adds no additional equipment in the wort path, and does not add to cleaning.

Other design criteria included that the home brewery location in a temperate climate allows for brewing in the glorious outdoors, so this rig uses 120V for (USA mains) plug and play readiness. (Although this system can operate at 240V/30Amp, that would require being tethered to an installed dedicated circuit in the brewery). As implemented: the 4500 Watt 240 Volt heating element run at 120 Volts produces 1125 Watts, sufficient to maintain mash temperature, and draws 9.3 Amps. Thus the 120V RIMS tube circuit, together with the pumps and electronic controllers (PID), runs on a single 120V 15 Amp mains circuit.

The ability to quickly heat water to strike temperature or boil, subsequently automatically maintain precision temperatures during the mash, no stirring, and only one kettle to clean; this makes for a expeditious and enjoyable brew day with consistent results.

More pictures are here:

http://www.flickr.com/photos/115125929@N08/sets/72157640487505774/

And a video tour here:

[ame]http://youtu.be/KrCy3reG82o[/ame]

or here:

www.youtube.com/channel/UCeUfIH0seYepqQ6Hgvp1qrg/videos

This forum and others are very helpful in providing needed information on re-entry into home brewing, building the brew stand, and initiating full grain mashes. There are previous descriptions by other brewers where the HLT is directed via a CCF Chiller to maintain mash temperature. These concepts are extended and adapted into this single vessel BIAB design, in which there is no HLT. The earliest reference was possibly by Baltobrewer in 2004, (and then blogging on papyrus, the first description of moving water through a copper coil was by Archimedes ;-). So some of these concepts have been around for a long time.

Thanks!

TAGS: BIAB HERMS RIMS, Brew In A Bag, Heat Exchange Recirculation Mash System, Recirculation Infusion Mash System, RIMS tube, Convoluted Counterflow Chiller, Wort, Brew Stand, Brew Sculpture, Brew Automation, Mash Temperature Control, PID, Home Brew, Home Brewery Setup, Single Kettle Vessel, Electric Brewery, Propane, Gas Fired, Beer, Largus1776