AdamCanFly

Well-Known Member

Thanks! Yeah, they're the auber switches.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

I was just thinking about something on mine. All of my controls are on the lid which is not hinged. That's going to make it hard to open it up and set the list somewhere safe. Would it be possible to create a wire harness so I can remove the lid? Anyone have any experience with something like this? Is it hard to do?

Click the link and then choose the amp size you want.

http://www.grainger.com/Grainger/fuses/fuses/electrical/ecatalog/N-8d0Z1z0nzys?contextPath=Grainger&xi=xi

Edit: Adding pn for switches 2-4

http://www.automationdirect.com part number GCX3192-120

http://www.automationdirect.com/adc/Search/Search?searchquery=GCX3192-120

The 1A fast blow is the regular 1A fuse (as opposed to a slow blow fuse).I feel like I'm blind, I can find the 1a fast blow fuses but I cant find the regular 1a or the 10a fast blow fuses

Thanks for putting everything on an nice elementary level for me

Thanks for putting everything on an nice elementary level for meSo I see JS guitar reccomends westmarine bus bars. But P-J's diagram calls for 4 terminal strips. What/where is the correct part for the job?

I got it dialed in it seems. I guess I just didn't know what I was doing before. I have the Pb set to 3 and it seems dead on now. I set t to 2 if I remember right and hyst to 2. I initially set P to 1 based on some reading here but I ran an autotune and it set it to 80.

I tested both outlets with my hlt since I need to replace the element in th BK and replace both sight glasses. Both element outlets worked perfectly

It held 150 in automatic mode and boiled in manual mode without a hitch. I took some pics. My location's boiling temperature is around 210.4 degrees, so at the moment the sensor is reading between 210-211 (switching between them). I may fine tune the Pb setting a bit more later if needed.

It boils just like I expected. I think it took around ten minutes to boil from 150 degrees.

Pic 1: plugged in to the HLT outlet

Pic 2: holding at 150

Pic 3: boiling in manual mode

Pic 4: BK outlet

Pic 5: Boiling! No pulsing. Just a nice steady boil.

Now I just need to prepare my brewing area and I'm in business!

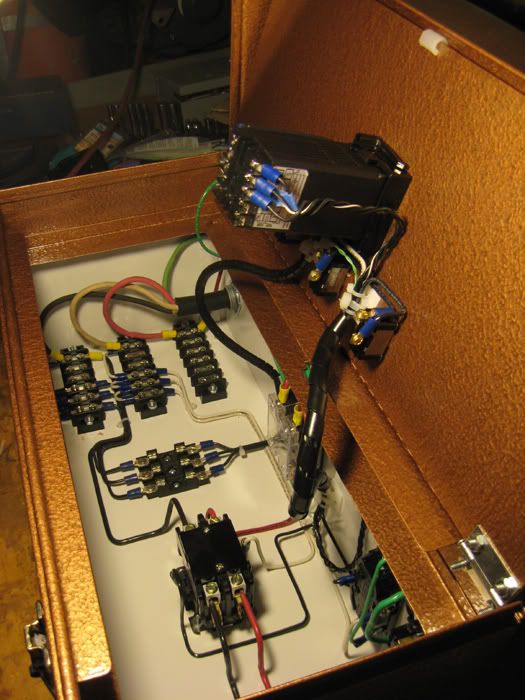

Your panel looks great, but I can't seem to find a picture of the inside of your build. Would you mind posting some pictures of the inside finished wiring and so forth? Also, did P-J or yourself ever build one with the push button switches detailed in the original wiring diagram? Lastly, how could I adapt this build to control my RIMS tube for my single tier propane rig? The only electric component in my brewery at this point will be the RIMS tube as I don't have the desire to go electric, yet. Thanks for the help in advance.

It can be done - but - you are entering a whole new ball game with that plan. Controlling the output temp of a RIMS setup is really dependent on precisely measuring the output temp - which in turn is dependent on the flow rate and the placement of the temp probe and the probe type. Any changes in any factor will dramatically effect the results. Good luck with that. And if you go that route, please let us know what you did....

Lastly, how could I adapt this build to control my RIMS tube for my single tier propane rig? The only electric component in my brewery at this point will be the RIMS tube as I don't have the desire to go electric, yet. ...

First thing to try is to pull the fuse going to the E-Stop switch and try again. That will tell you if it is wired correctly. If the breaker still trips you need to look at how you have wired the neutral output of the GFCI breaker. The neutral must be from the breaker its self for the output to your controller.So I finally finished the spa panel and went to plug in my control box for the first time and am having some problems. Right when I plug in the box it pops the GFCI.

I used the attached diagram but made a few changes. I used this one because I wanted two LED's but I didnt need the timer. It's wired exactly like this minus the timer and it's connections.

Let me know if this is the proper way to do this or if something else should be changed when removing that item from the diagram.

If that's correct let me know if you have any other specific suggestions to check. I haven't had time to check anything yet but just wanted to get feedback on this first. Tonight I should have time to open it up and double check all the connections.

Great diagnostics. Well done....

Basically when using my HLT it is blowing the GFCI. Once I got the BK complete I was able to do some further testing and the problem seems isolated to the HLT.

...

The only thing I haven't switched is the element. The only thing that I can think is happening is a very small amount of water is getting past the seal on the kettle and causing the GFCI to pop. I had a little trouble getting the element into the HLT because it was hitting my pickup tube so I did have to make the hole slightly larger than the one one the BK. It is barely larger though, just a couple more passes with a grinding attachment on the dremel tool. I have not seen any visible sign of water leaking but cannot think of what else may be causing this.

My plan to fix this is to get some high temp food grade silicone and put it around the threads on the element. If this doesn't fix it the only other thing I can think to do is replace the element but that seems unlikely to be causing this issue.

...

Thanks for the response. It's probably me overlooking them, but the link you posted here just links back to the original thread, which I can't find any pics of the inside of your controller. Any chance you have some or can take some? Thanks.Thanks for your comments. Here's some pics of the inside: (it's built directly from the 1st diagram at the top of p.3)

https://www.homebrewtalk.com/f170/suggestions-controller-249400/index4.html

The pushbutton switches are an easy change to make and Adamcanfly is doing just that (as he showed a page back or so in this thread). There are also some more recent similar builds that are using those switches.

To your last question, I'll defer to P-J on that one. There's a bit more info needed to determine what your needs are for that.