craigsphillips

Well-Known Member

It can be done - but - you are entering a whole new ball game with that plan. Controlling the output temp of a RIMS setup is really dependent on precisely measuring the output temp - which in turn is dependent on the flow rate and the placement of the temp probe and the probe type. Any changes in any factor will dramatically effect the results. Good luck with that. And if you go that route, please let us know what you did.

IMHO, a better and more easily controllable setup would be to use a HLT with a heat exchanger to accomplish the task. Temp control is easy.

Thanks, P-J. I didn't realize I was entering new territory incorpating a RIMS tube. Not saying I'll never go HERMS, and considering what I have already built and bought, I think I'm going to stay the course with my RIMS tube and not switch to HERMS, but I could still use some help from the "experts". I've seen some threads where you've helped some others incorporate RIMS in their controller setups, so I was hoping you could help me simplify things. I've already built the RIMS tube and my direct fire keggles. The controller is the only missing link. My controller should take a much simpler design than an all electric rig. The only electric component I need to control is the RIMS tube, which has the following components. I'd like to run it at full flow to maximize the amount of whirlpool I can create in my mash tun, so restricting flow was not something I planned on doing. The temp probe is located in the outlet end of the RIMS tube.

Liquid tight 4" type K thermocouple 1/2" NPT - Auber TC-K100M1/2NPT

120V 1500W Low Density Heating Element - Grainger 2E295

Pump - March 809HS

Here's the other stuff I planned on buying thus far.

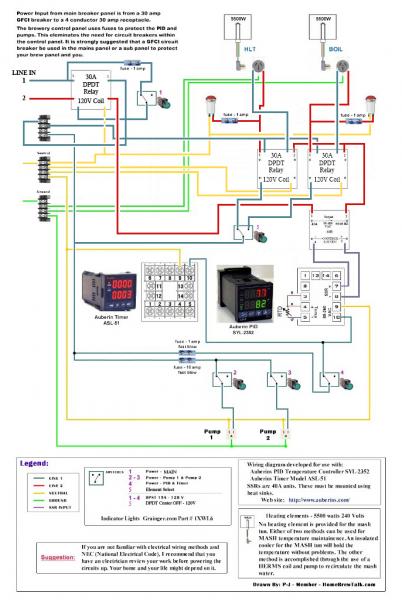

PID - Auber SYL-2352

40A SSR - Auber RS1A40D40

Heat sink - Auber HS40

Enclosure - Auber Pbox16

Switches - Pilot Automotive PL-SW26 (Kind of TopGun'ish)

I'm certainly open for suggestion and looking for help planning and wiring things up. You probably thought I'd never ask, but would you be willing to help me with one of those famous diagrams of yours? Thanks, man.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)