Gonefishing

Someday I'll stop procrastinating

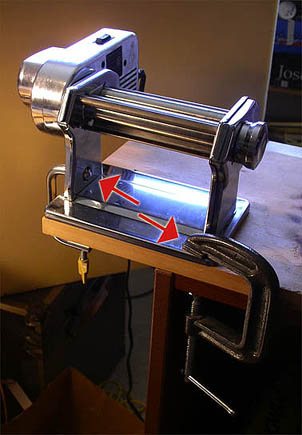

OK...it works! I took it apart and roughed the rollers by hitting them MANY times with the edge of a big file. Took maybe 30-45 minutes to rough them both up (they are both driven BTW) and once I got it back together I went to the basement, got some grain, dropped it in and turned the crank.... milled grain was the result! The gap is adjustable too, so I was able to get what I think it going to work pretty well. I think I'm going to be very happy with my $15 mill!

I think tomorrow night being Friday I may just have to BREW!!! I will have to do a partial boil though, no cooler yet. No outside burner either, and it's supposed to be cold and rainy here then.

I think tomorrow night being Friday I may just have to BREW!!! I will have to do a partial boil though, no cooler yet. No outside burner either, and it's supposed to be cold and rainy here then.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)