TerapinChef

Well-Known Member

I was hoping to cut the center of the base away and kind of fold the vertical legs out at the bottom for bolting to something...it wasn't a well thought out plan

I was hoping to cut the center of the base away and kind of fold the vertical legs out at the bottom for bolting to something...it wasn't a well thought out plan

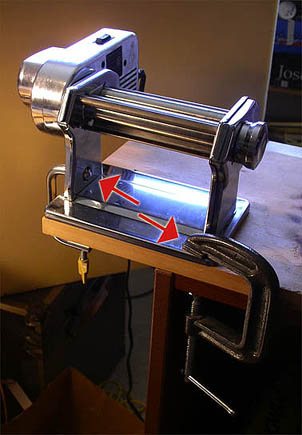

That's what I did...took the end covers off so I could get to the nuts on the base bolts, then just mounted it to a board with a whole cut in it. Here's the board (sitting on the cover to a Homer bucket).

And here's the completed mill

Use 8-32x1" screws for this and you won't have to enlarge the holes in the uprights like I did with my 10-32 screws.

The board is a plastic composite thing that I got on a jobsite thinking I'd use it in my camper project...way handier in the brewery!

All those questions and more are answered in my new blog entry...and a whole lot more pictures.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

So for about 1/4 of the price, you can just buy the Pasta model and DIY it a little bit and BAM! Now you have a Grain Mill.

So I haven't posted in a while, I have to admit it's because I was kind of jealous. Gonefishin snuck ahead of me one this one and I was hoping to be the leading researcher. But I have not given up. That'll teach me to post my ideas before I start working on them...I'm going to play around with the finish on the rollers and see if I can't come up with a good way to knurl those rollers, then work on motorizing and stand building. The nice thing about the mill standing so high off the base is it gives you a lot of room to mount a pulley if you needed to...

Been reading this thread and getting excited about being able to afford a mill. But there hasn't been anyone yet actually brew a batch with it and post efficiencey results. Anybody? Only number were Revvy missing by 23 points. I know this was first pass no adjustments, but the only numbers I've seen and not too promising. Anyone. I really wanna see someone posting saying they nailed their OG

Revvy said:I wonder if Harbor freight has a cheap knurling bit, maybe one that couled even fit in a dremel tool, and maybe you can rig up a jig and knurl them yourself.

Here's a link with a video of motorizing it with an electric juicer machine.

Polymer Clay Bytes! - Tina Holden's Beadcomber: Best Pasta Machine Motor for Polymer Clay

Aren't you guys lucky I've walked this world as well, years ago I was a polymer clay artist and in the Natl Guild...

So I haven't posted in a while, I have to admit it's because I was kind of jealous. Gonefishin snuck ahead of me one this one and I was hoping to be the leading researcher. But I have not given up. That'll teach me to post my ideas before I start working on them...I'm going to play around with the finish on the rollers and see if I can't come up with a good way to knurl those rollers, then work on motorizing and stand building. The nice thing about the mill standing so high off the base is it gives you a lot of room to mount a pulley if you needed to...

Hey, I'm sorry... I didn't mean to steal your thunder or anything. I am just one of those impulsive do-it-now-or-never-do-it types and I was intriqued with the idea that I might be able to mill grain for $20. Mine is just a wicked crude prototype, you can certainly be the one who figures out how to make the rollers work really well so the output speed is higher. Please don't be jealous that I jumped on this ... let's just all work together in HBT fashion and make this something that people come to HBT for the tech advice on this beautiful little gadget.

I'm more worried about "Can I do it on a wood lathe without messing up the lathe because it's not mine" than I am about spending the $25 bucks. I'm pretty sure if I buy that knurling tool, a few people in the area with pasta machines are going to come calling....

I was gonna say the same thing, if you got the knurling tool I would definitely bite the bullet and convert the one I have...

Square stock wouldn't work...the hole is round with just a slot for the tang on the handle. However, the shank of a cheap screwdriver might work. All you'd have to do is break the handle off...viola...instant round driveshaft with the correct drive tang on it! (Although I think the handle has only one and the screwdriver (we're talking handle end here) would have two so one might need to be ground off.

The question, I suppose, is whether it would be better than a $20 Corona mill. Seems like the hardest part will be getting the rollers right.

I have used them, and basically yes, that's what you do, but there's more pressure there than you could ever do by hand. They do sell hand knurlers though...they look like a big pipe cutter, but I think they're pretty pricey.

I have a wood lathe that I don't use... too bad we don't live close to each other.