TBLbrewer

Well-Known Member

Did you keep the same o-ring on the bottom outlet that it came with?

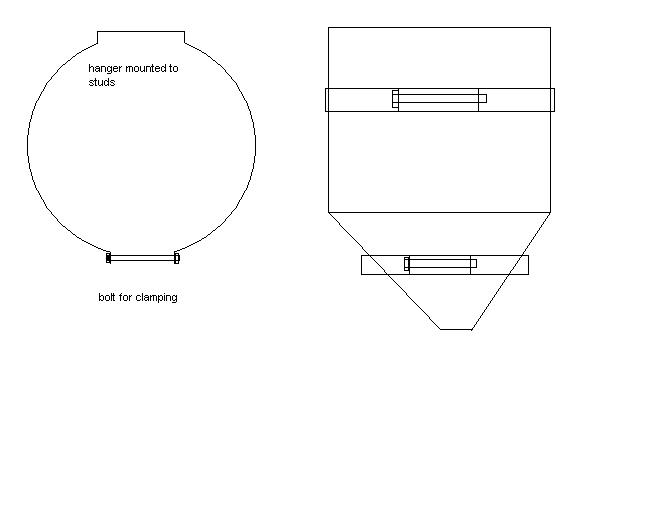

Why do we want conicals again?i would think a sheet of ply with the diameter of the conical about 5" up from the bottom of the conical and another the diameter of the vertical sides of the conical. would slide in and out for cleaning. you could also use flat steel strapping from homedepot. bent around the conical and use like clamp.

kinda like this. for the clamp strap type setup.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Was just thinking that it might be a good idea to find some kind of gasket to go around the hole in the stand. I think over time you might get a bit of wear on your fermenter from sitting in there all heavy and stuff with that raw wood rubbing on your tank. Just a thought.

For all the Canadians out there I got one from https://www.polywest.ca/index.php?link=home for about $65. Shipping was only $17 by greyhound and it arrived four days after ordering. I just built a wooden stand and cant wait to give it a test run.

I got my 15 gallon tank and have assembled a valve and drilled the hole for the airlock. When I opened it, I noticed a REALLY STRONG plastic smell. I washed it out and let it soak with oxy clean for a day, no change! I have read that a mixture of vinegar and baking soda with water and soaking for 48 hours will fix it. I will advise but I would NOT buy one of these until a fix is determined. I would have to say as-is we would be brewing a "plastic pail ale" :cross:

eta525 said:I have a couple of these plastic conicals that i bought off someone in my homebrew club who never used them, so I'm not sure which manufacturer they came from.

As for the CO2 leakage though, when I first used them I also had problems with the CO2 leakage and having nothing coming up through the airlock. The beer turned out fine, but I was still concerned. So I got a tube of food grade lube and put a large bead around the top of the conical tank and screwed the lid down into it. So there's a slick mess around the rim, but none of it gets into the tank, and effectively seals the lid shut, so the airlock bubbles and nothing gets in. Hope that helps!

Has anyone done anything to the inside of these at the outlet port? Mine has the huge plastic nut on the inside that creates a pretty big lip for the yeast to settle into, I was thinking of filling it with food grade sealant?