brianccarr

Well-Known Member

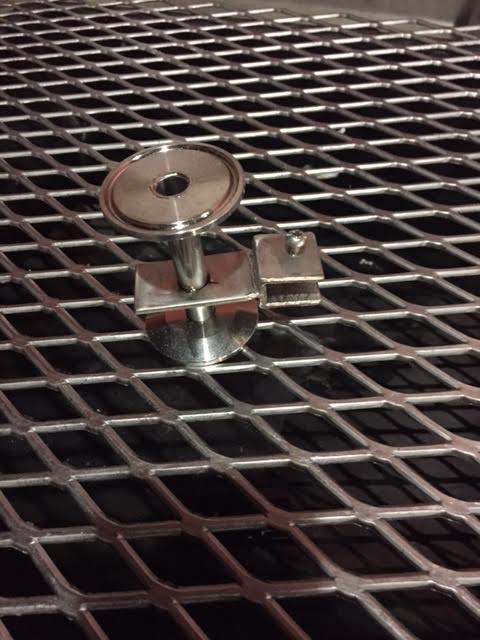

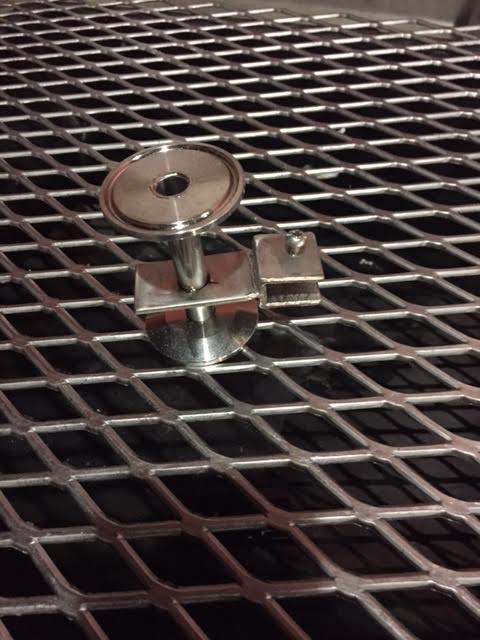

The re-circulation tube mounts to the basket via a removable bracket fitting. The same bracket simply mounts to the kettle for whirlpool. Tim at Colorado Brewing was very helpful and quick to respond. I can't see any reason to go with the Nano Pro-Down Under for my needs as a home brewer.