Thedude907

Active Member

- Joined

- Jun 9, 2017

- Messages

- 31

- Reaction score

- 2

Okay. I've been reading trying to figure out my self what is going on. From what I can gather it's a few things. First off my first two batches are great. They didn't poison me lol. Any way.

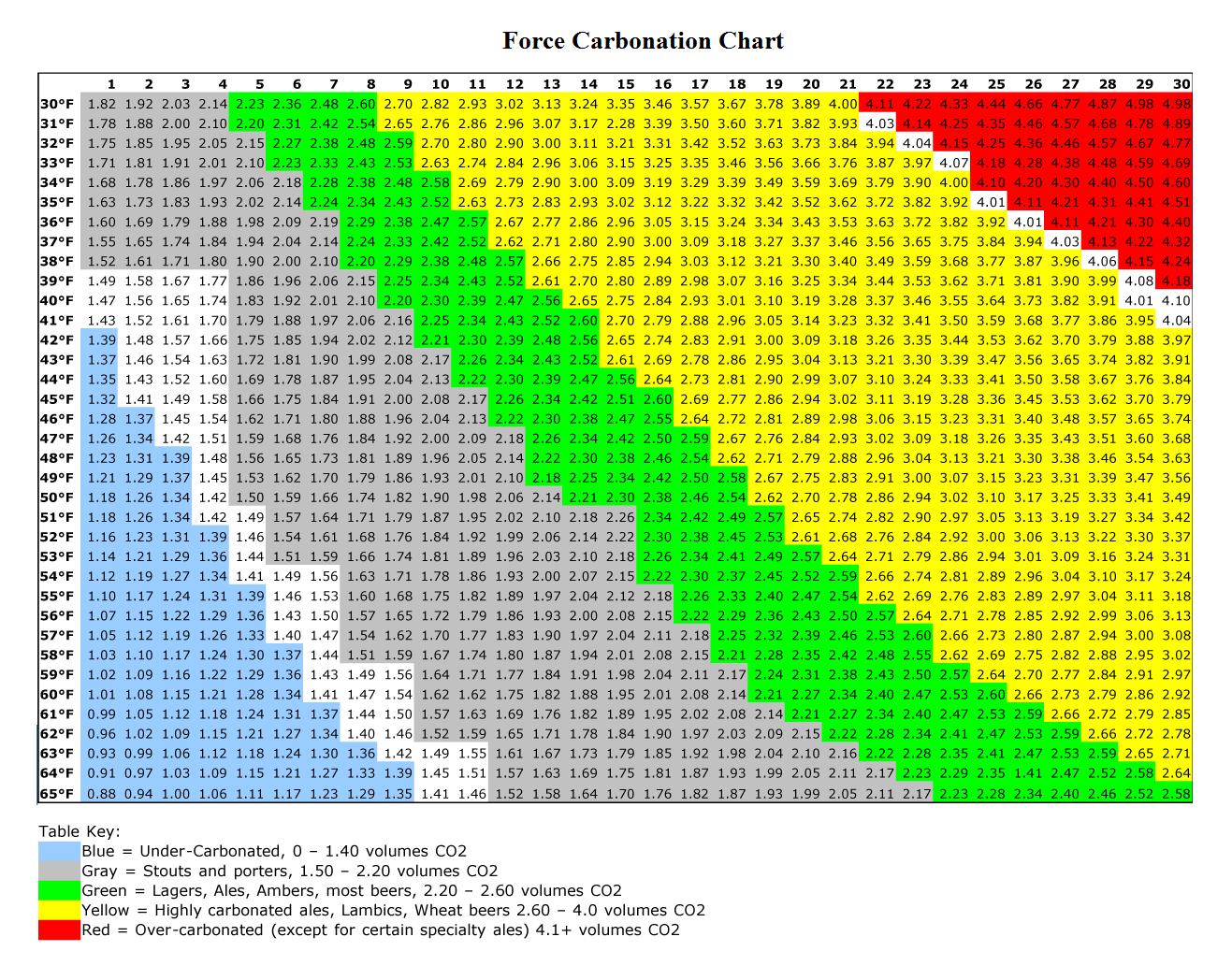

I have two kegs I force carbed at 30 psi. Shook them and kept them cool for man days. I have them in a freezer that is temp controlled to 38 f. I have two short 16 in tap lines. They foam. My blonde not so bad but my ipa comes out foamy. So I added a longer tubing. 10 foot. Still foam.

I am using like 3/8 or a 5/16 tubing. I think i should be using 1/4. Don't know

My thoughts are 1 tubing length and diameter issue 2 regulator issue. I think my Guage may be off. Because it hisses at 15 psI the prv on the regulator. Could be a bad orfice plate. Or 3 carbonation doesn't work at my house because it's buit on an Indian burial ground.

Any and all help is appreatianted. Thanks for any replies.

I have two kegs I force carbed at 30 psi. Shook them and kept them cool for man days. I have them in a freezer that is temp controlled to 38 f. I have two short 16 in tap lines. They foam. My blonde not so bad but my ipa comes out foamy. So I added a longer tubing. 10 foot. Still foam.

I am using like 3/8 or a 5/16 tubing. I think i should be using 1/4. Don't know

My thoughts are 1 tubing length and diameter issue 2 regulator issue. I think my Guage may be off. Because it hisses at 15 psI the prv on the regulator. Could be a bad orfice plate. Or 3 carbonation doesn't work at my house because it's buit on an Indian burial ground.

Any and all help is appreatianted. Thanks for any replies.