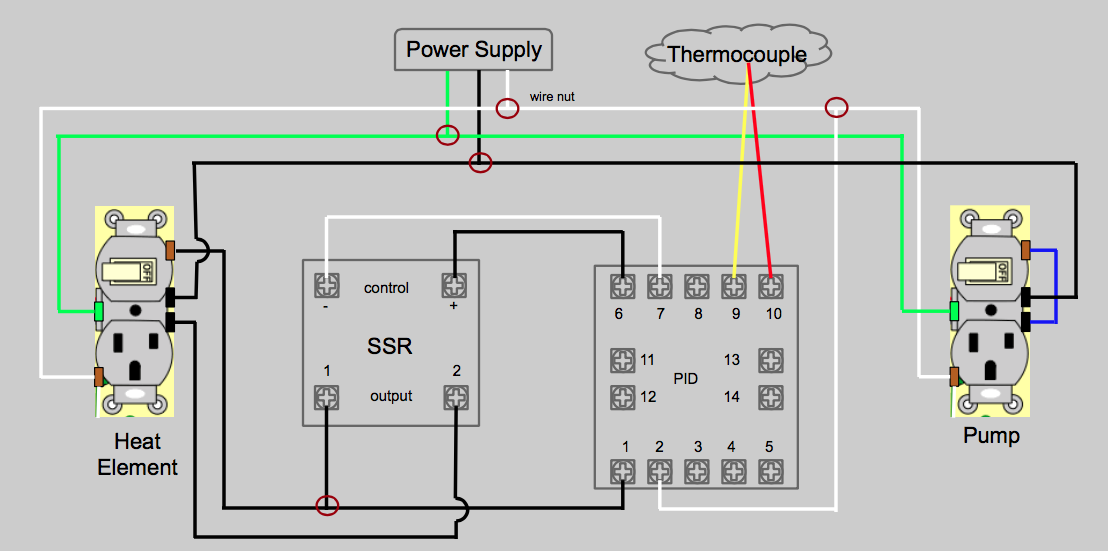

Excuse my ignorance, but can you run the independent element AND the PID side of of the same wall outlet? It looks like that's what you're doing but I just wanted to make sure you didn't have a higher amp circuit installed.

Also, I would like the option of doing 10 Gallon batches. Would the two 2000W 120V elements be able to boil the required water/wort for a 10 gallon batch?

Thanks for the write up, this is great stuff!

Also, I would like the option of doing 10 Gallon batches. Would the two 2000W 120V elements be able to boil the required water/wort for a 10 gallon batch?

Thanks for the write up, this is great stuff!