homebrewdude76

Well-Known Member

5500W ULD, I think Stainless element in my RIMS tube.

I goofed and blew it out yesterday.

I really just use it to heat mash water, then maintain mash temps. A few times I attempted to step up from mash temp to mash-out temp. 152 to 168

If I want to get more into step mashes should I look into a lower wattage element?

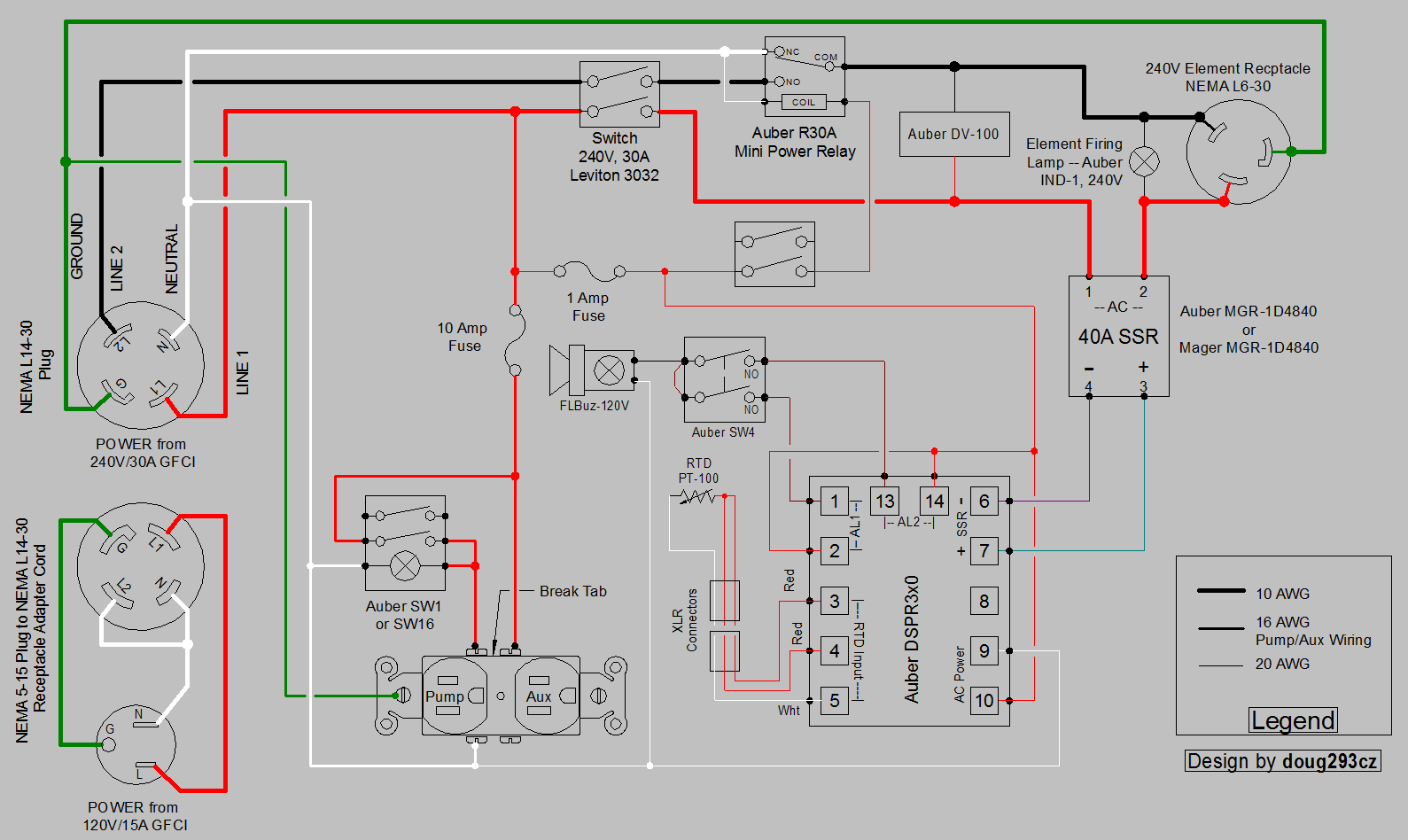

I built my own panel, so I guess I could look into a switch for 240v to 120v? Is it just switching off one leg??

Also not seeing where to get a straight, SS ULD element.

This one says LD

https://www.amazon.com/DERNORD-Fold...uPWNsaWNrUmVkaXJlY3QmZG9Ob3RMb2dDbGljaz10cnVl

This one says ULD, but not SS

https://www.amazon.com/Camco-02933-...2883&sprefix=camco+5500w+240v+,aps,106&sr=8-1

I goofed and blew it out yesterday.

I really just use it to heat mash water, then maintain mash temps. A few times I attempted to step up from mash temp to mash-out temp. 152 to 168

If I want to get more into step mashes should I look into a lower wattage element?

I built my own panel, so I guess I could look into a switch for 240v to 120v? Is it just switching off one leg??

Also not seeing where to get a straight, SS ULD element.

This one says LD

https://www.amazon.com/DERNORD-Fold...uPWNsaWNrUmVkaXJlY3QmZG9Ob3RMb2dDbGljaz10cnVl

This one says ULD, but not SS

https://www.amazon.com/Camco-02933-...2883&sprefix=camco+5500w+240v+,aps,106&sr=8-1