lorne17

Well-Known Member

- Joined

- Jan 14, 2013

- Messages

- 360

- Reaction score

- 30

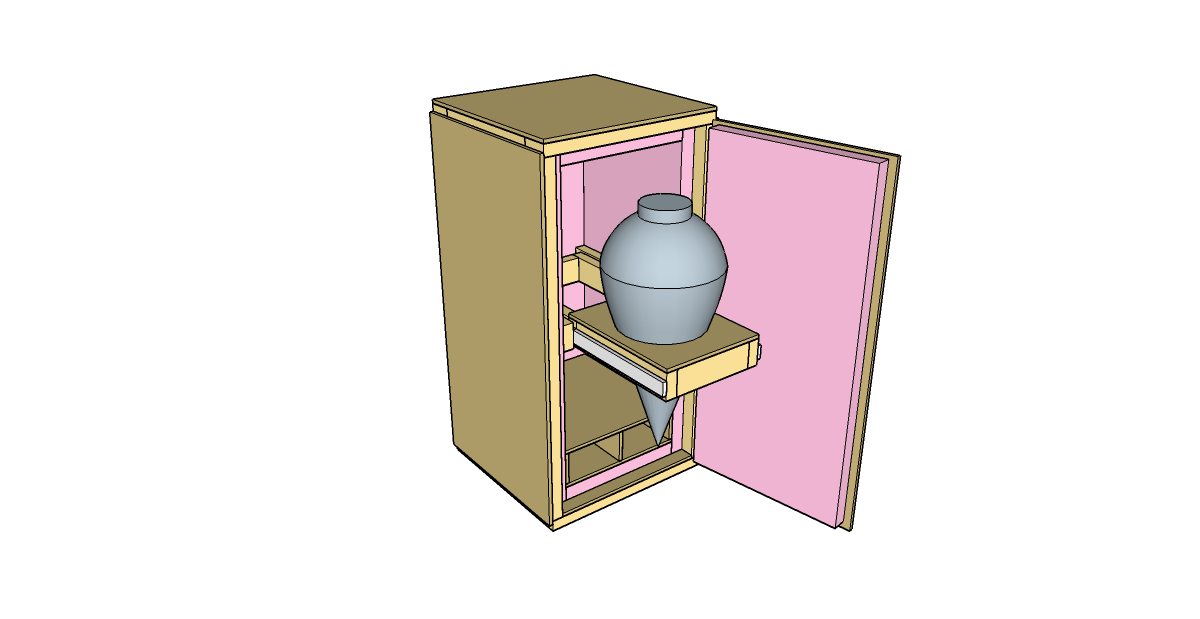

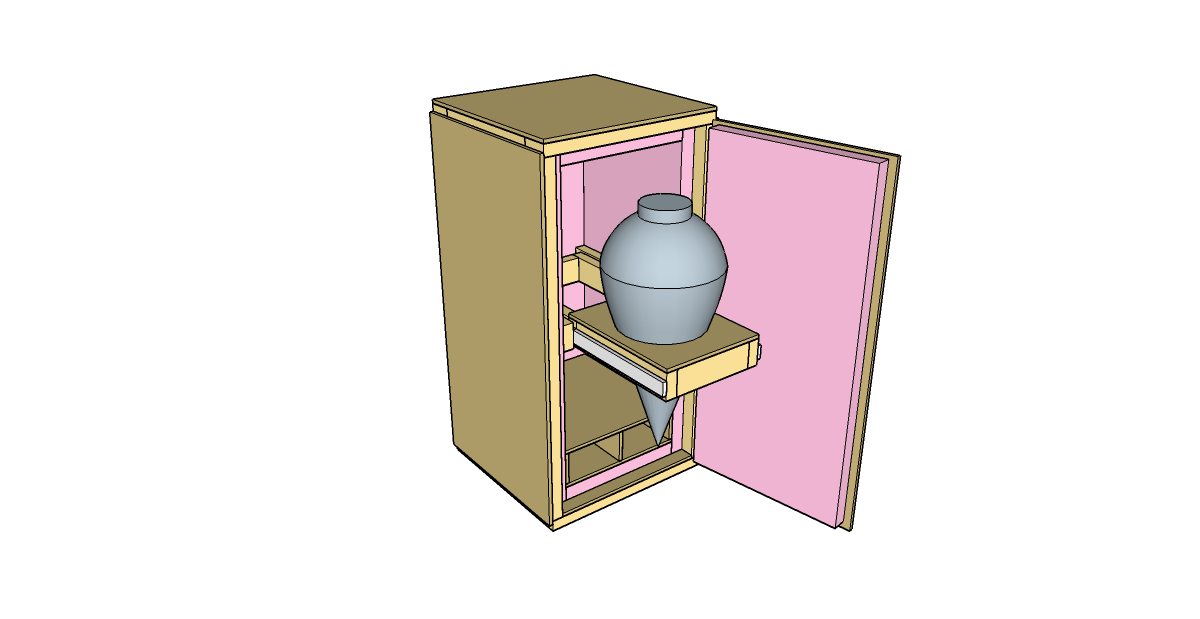

For anyone who's interested in creating a fermentation chamber for your FastFerment...here are my plans. I tried to get creative with the name, since the original SON OF A FERMENTER plans inspired me, I used that as a conceptual guide, I've just put my spin on it for FastFerment. So here's my "SON OF A FASTFERMENT CHAMBER" I'm open to suggestions before I go to cut!

Cons:

Suggestions, both good and bad, are welcomed! Even ideas of how to cut cost even lower!

Thanks,

Lorne

Cons:

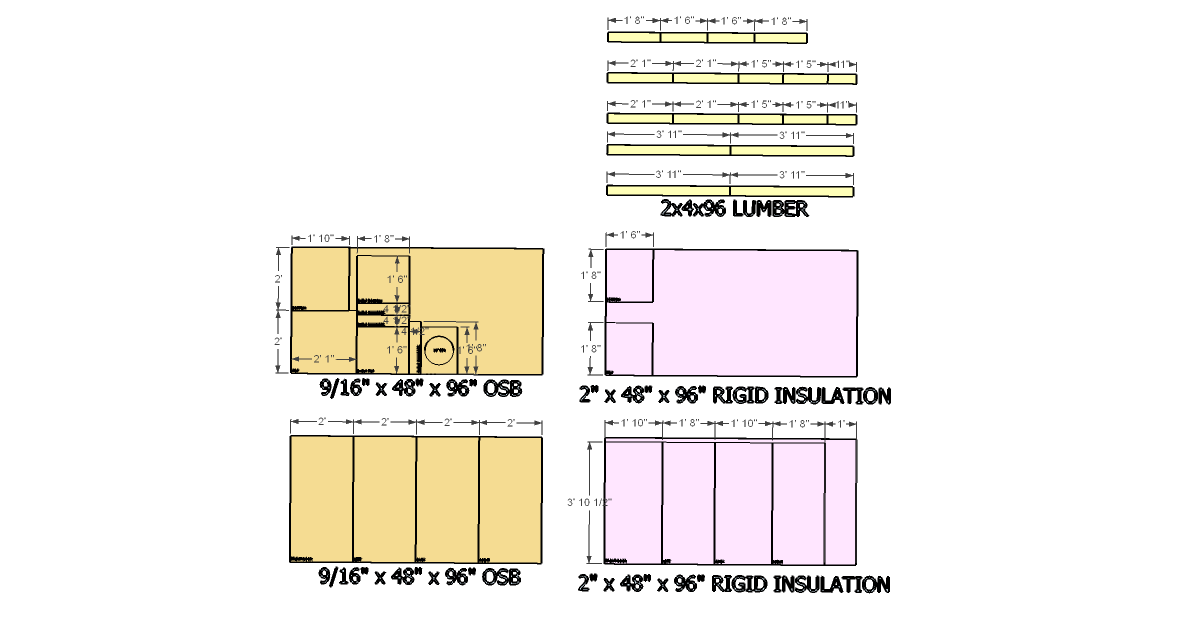

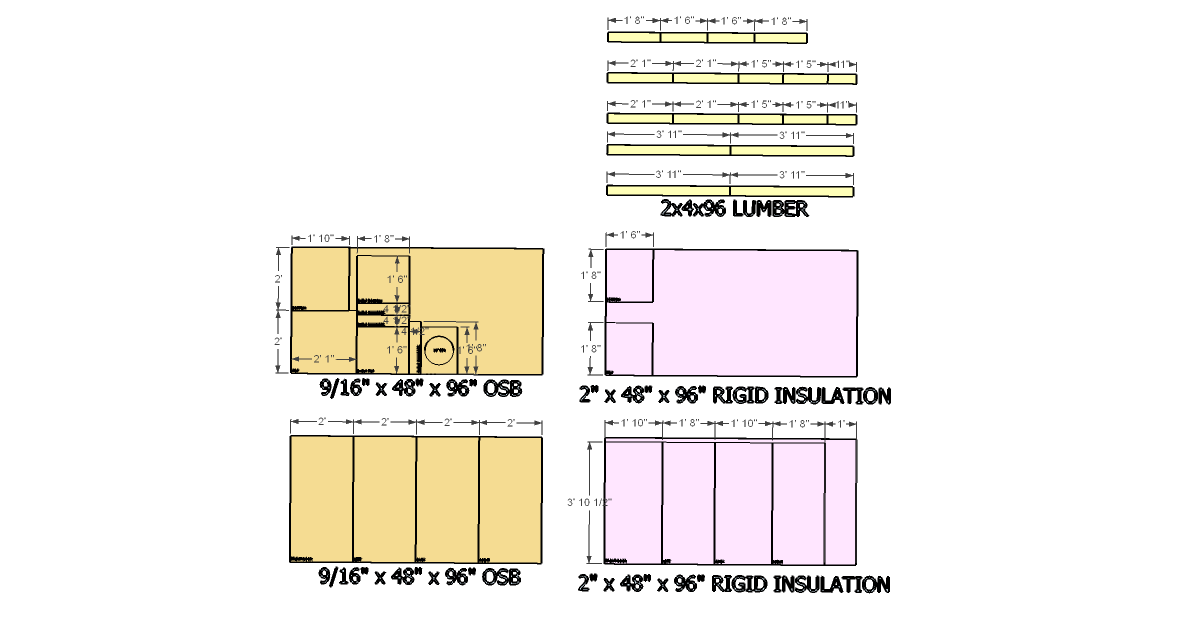

- I can't seem to get it any shorter to prevent the waste of the Rigid Insulation from those last two 20"x18" pieces. Anyone got any ideas? HD sells 1" Rigid 24"x 24" which would work. But if I buy 4 so I have 2 2" pieces, then I'm almost to the exact same price as a whole sheet as the 24"x24" is just under $6.

- I also have about half a piece of OSB of waste due to the cuts

Luckily I have some 24"x24" OSB left over from another project.

Suggestions, both good and bad, are welcomed! Even ideas of how to cut cost even lower!

Thanks,

Lorne