wilconrad

Well-Known Member

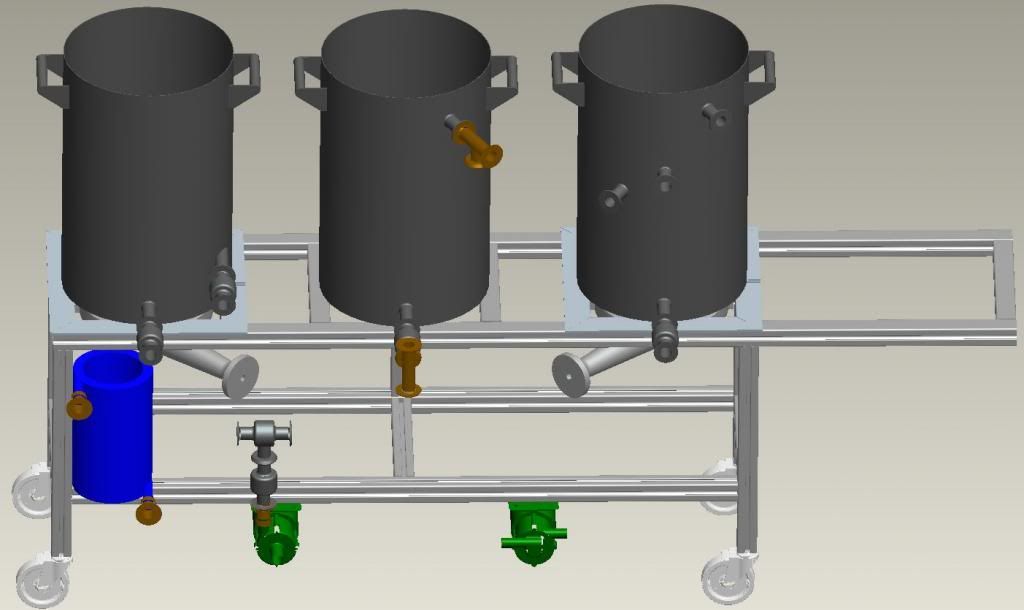

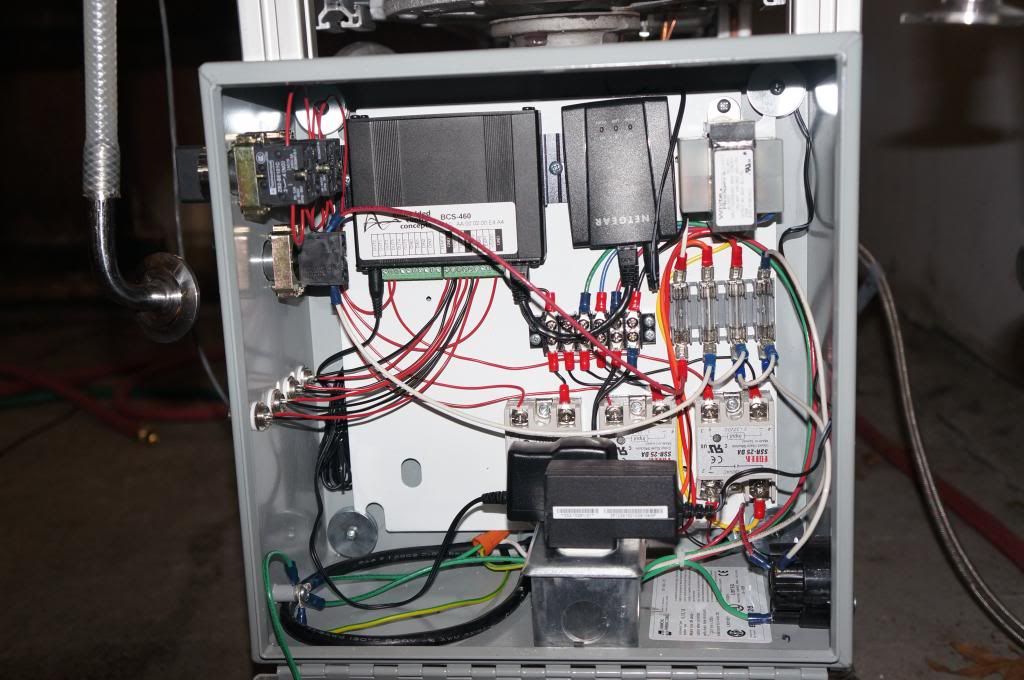

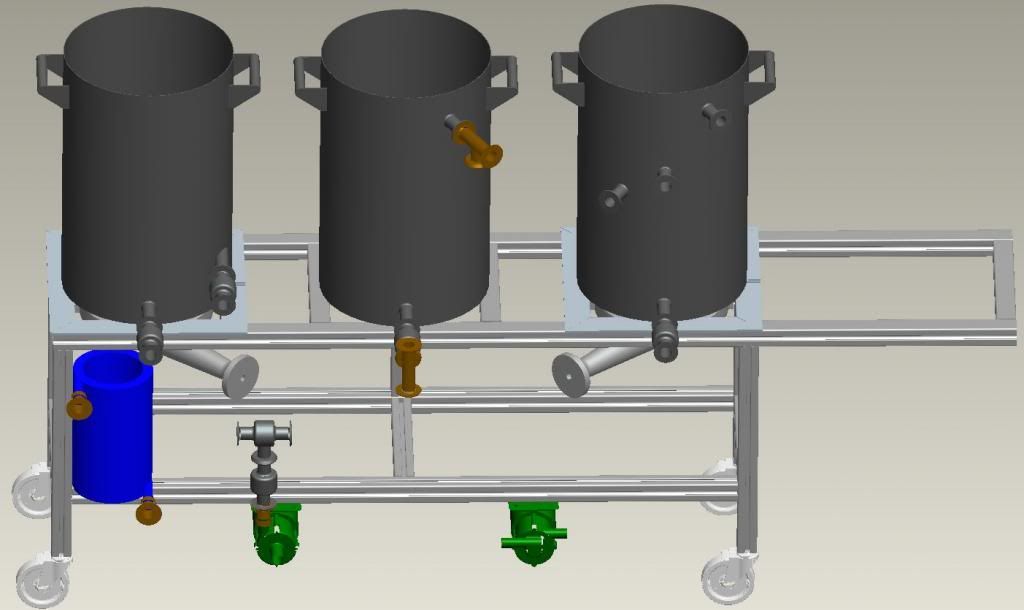

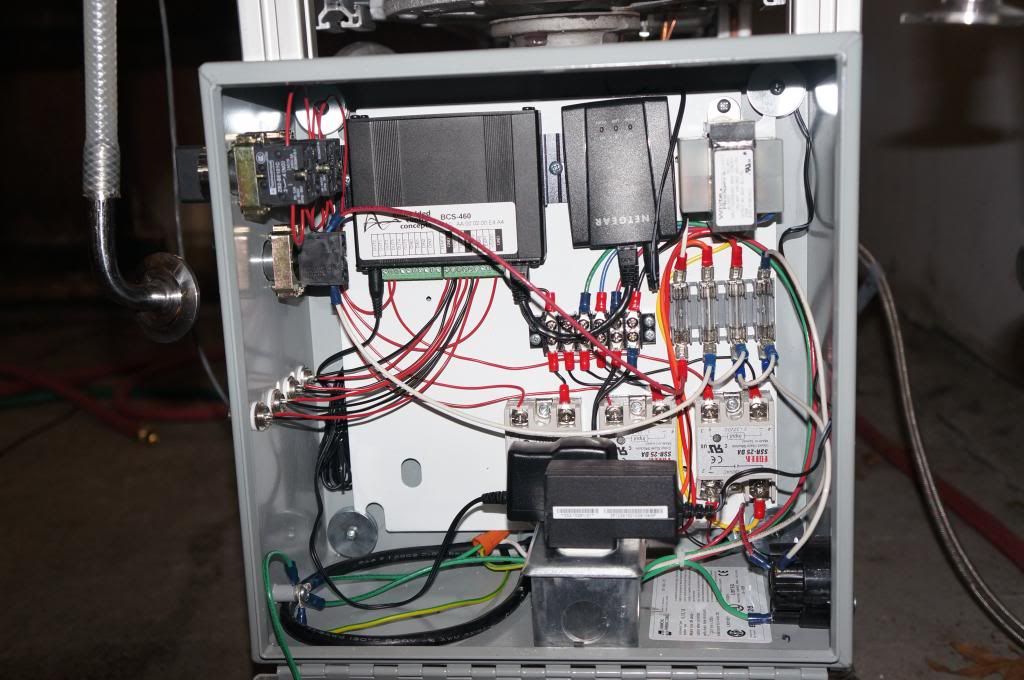

I recently finished my single tier stand build and since I found all the pics and discussion here on HBT so helpful as I was designing it, I thought I'd pay it forward by posting some shots here. It's a 9.2gal HERMS system; the vessels are from Stout Tanks & Kettles and the frame is built out of 80/20 aluminum t-slot extrusions. A BCS-460 handles the water and mash temps via a Honeywell VR8200 gas valve, and drives the 2 chugger pumps (inline for water, center inlet for wort). The chiller is a stainless counterflow from Williams Brewing. I found pictures more helpful than words as I was researching here, so I'll toss up some pics and feel free to ask any questions if you have them.

Thanks to all of you who have done the same in the past, as this was extremely helpful for me as I built this system!

Pro/E model of the stand:

Frame taking shape. At first I tried to cut the 80/20 t-slot extrusions with a chop saw, but that made an ugly cut and the blade just saturated with aluminum rendering it useless. So I dropped by my local hardware store and they had a toothed non-ferrous blade on their chop saw for cutting window framing; it cut through this stuff like butter and left a nice clean cut.

The frame is held together by socket head cap screws threaded into the ends of each extrusion section. The extrusions have a centered hole, so it's easy to run a 3/16-18 tap in and bolt it all together.

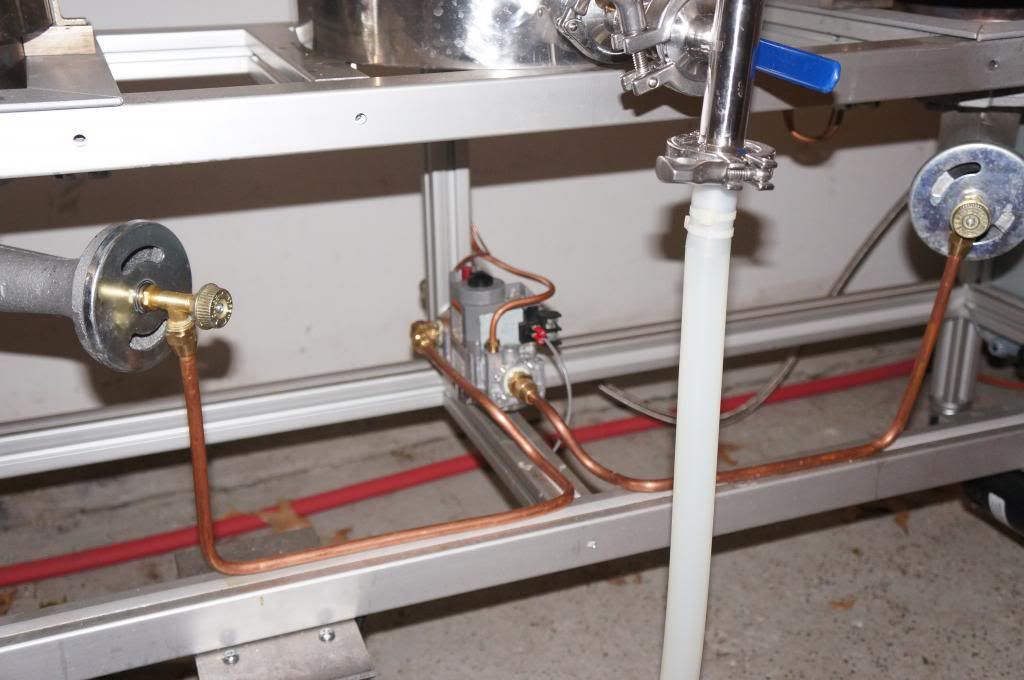

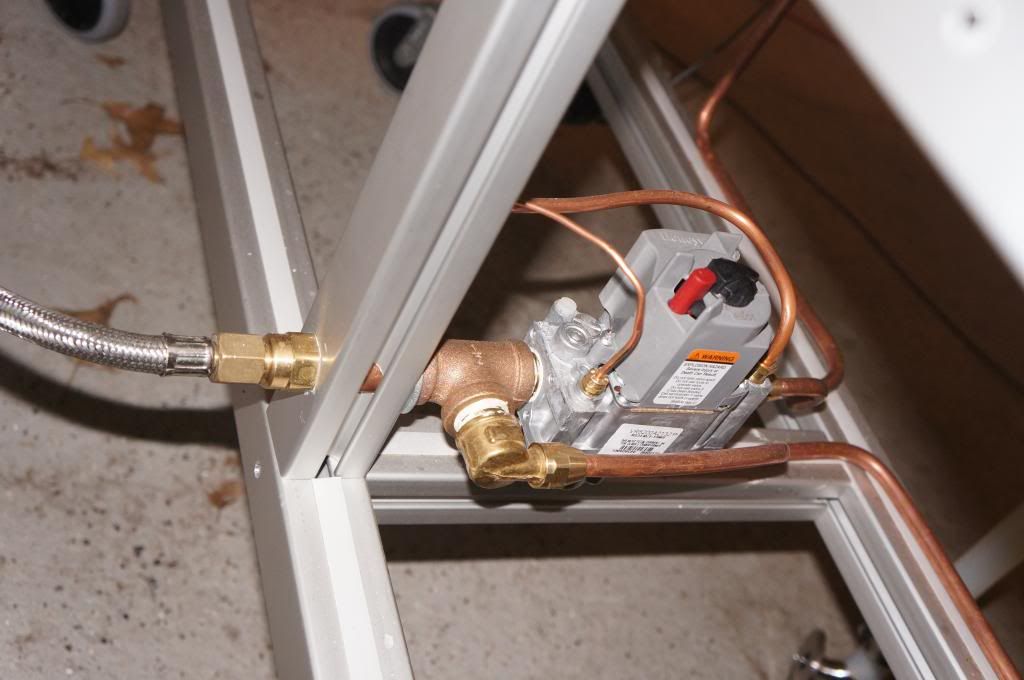

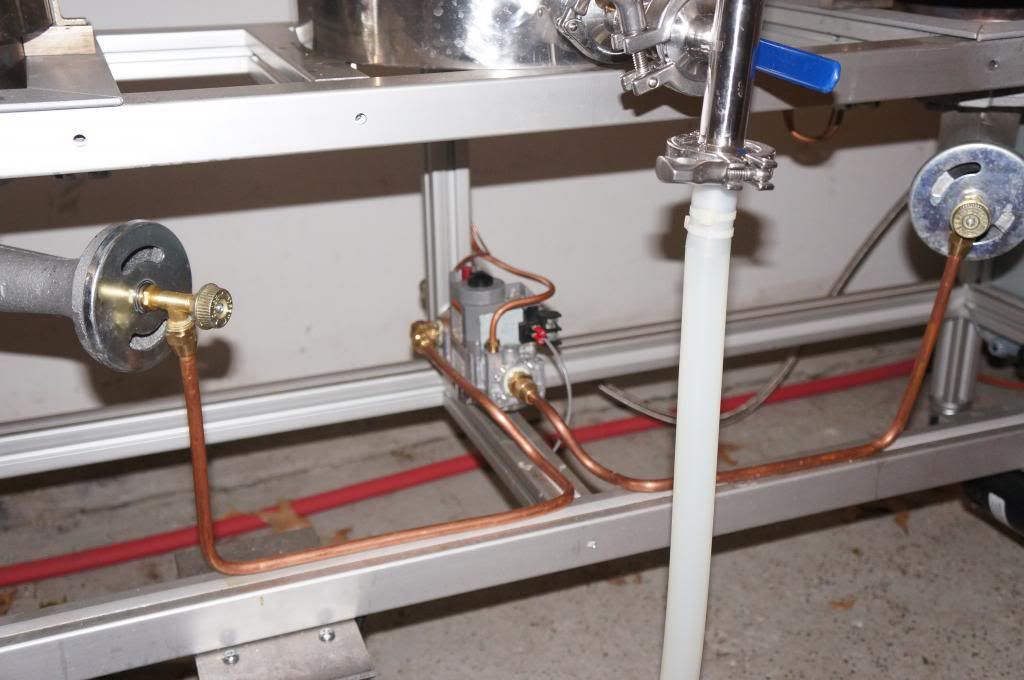

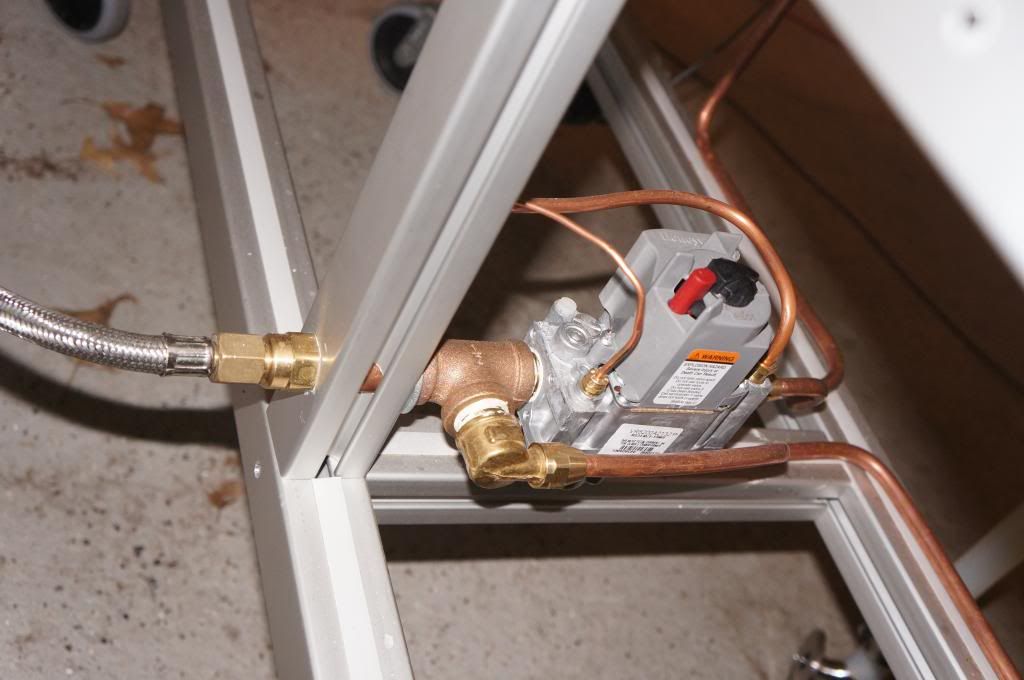

A few shots of the gas plumbing:

This system is running on low-pressure (11" WC) LP gas, the needle valves at each burner have an orifice that I drilled out to 5/64". This provides enough heat for a good rolling boil.

I didn't want to trust the aluminum framing to direct flame exposure, so I built some heat shields out of 2" angle iron (regular mild steel) and painted them up with VHT header paint. After curing these guys in the oven, they have put up with serious heat without issue. I also added a windscreen out of 20ga stainless sheet to direct the heat up to the kettle, and used 3/4" stainless square solid stock to support the pot and allow some "breathing room" for the burner.

The electronics are mounted in a 12"x12"x6" NEMA 12 enclosure:

Here is the full stand, nearing completion. I stained/sealed a piece of birch for the shelf on the right side of the stand, which has proven to be a useful addition.

I brewed the first 3 batches this weekend and the stand performed well, here's a shot of it running the mash:

Thanks again to everyone who posted writeups on their builds!

Thanks to all of you who have done the same in the past, as this was extremely helpful for me as I built this system!

Pro/E model of the stand:

Frame taking shape. At first I tried to cut the 80/20 t-slot extrusions with a chop saw, but that made an ugly cut and the blade just saturated with aluminum rendering it useless. So I dropped by my local hardware store and they had a toothed non-ferrous blade on their chop saw for cutting window framing; it cut through this stuff like butter and left a nice clean cut.

The frame is held together by socket head cap screws threaded into the ends of each extrusion section. The extrusions have a centered hole, so it's easy to run a 3/16-18 tap in and bolt it all together.

A few shots of the gas plumbing:

This system is running on low-pressure (11" WC) LP gas, the needle valves at each burner have an orifice that I drilled out to 5/64". This provides enough heat for a good rolling boil.

I didn't want to trust the aluminum framing to direct flame exposure, so I built some heat shields out of 2" angle iron (regular mild steel) and painted them up with VHT header paint. After curing these guys in the oven, they have put up with serious heat without issue. I also added a windscreen out of 20ga stainless sheet to direct the heat up to the kettle, and used 3/4" stainless square solid stock to support the pot and allow some "breathing room" for the burner.

The electronics are mounted in a 12"x12"x6" NEMA 12 enclosure:

Here is the full stand, nearing completion. I stained/sealed a piece of birch for the shelf on the right side of the stand, which has proven to be a useful addition.

I brewed the first 3 batches this weekend and the stand performed well, here's a shot of it running the mash:

Thanks again to everyone who posted writeups on their builds!