After a semi-successful attempt to nurse more life out of my old keezer, chronicled in this post, it finally died. So I built a new one and am posting some of this process here. I found various other posts helpful when looking for ideas, methods etc..

The Chest Freezer; I opted to buy a new one. I was able to pickup a 10.2 cubic foot Insignia from Best Buy on sale.

My old keezer was black but the new one was white. My wife often complained that it looked ugly. So I decided to surround my new one in wood. I understand that some chest freezers leverage the skin for heat dissipation so a goal was to allow at least some gap between the freezer skin and the wood I was surrounding it with.

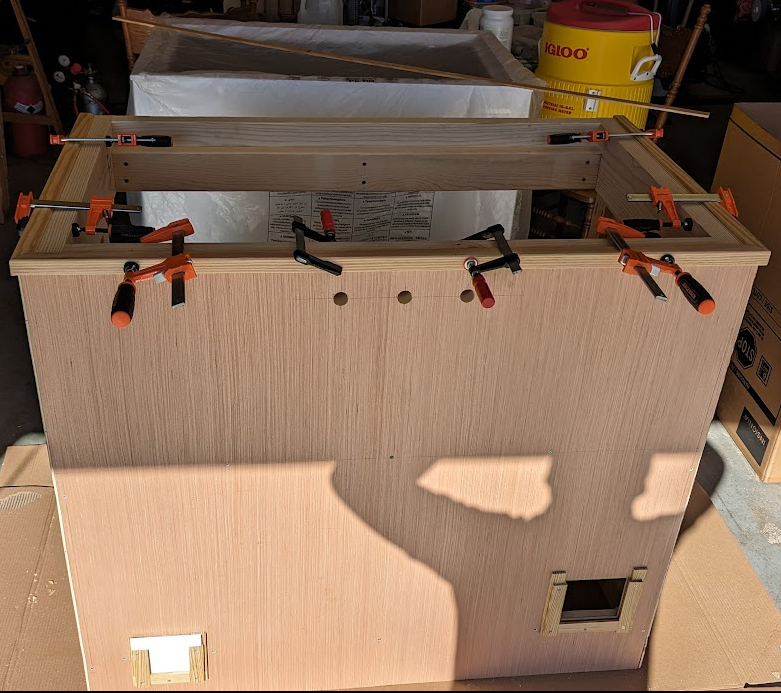

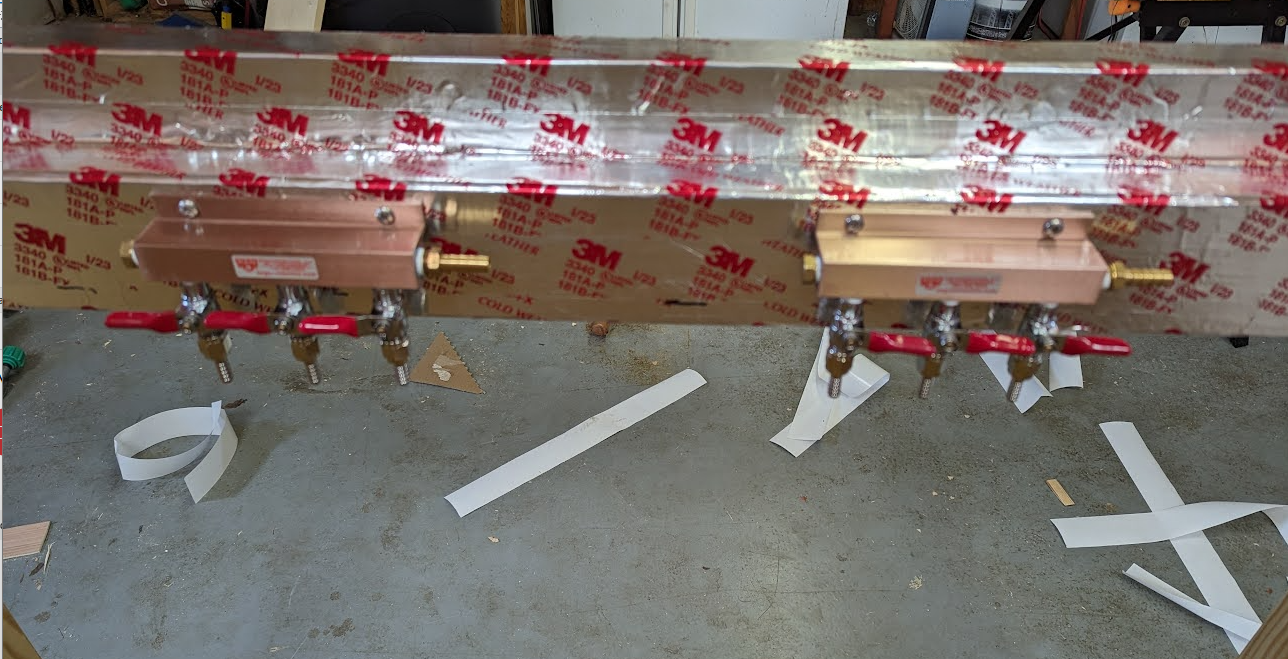

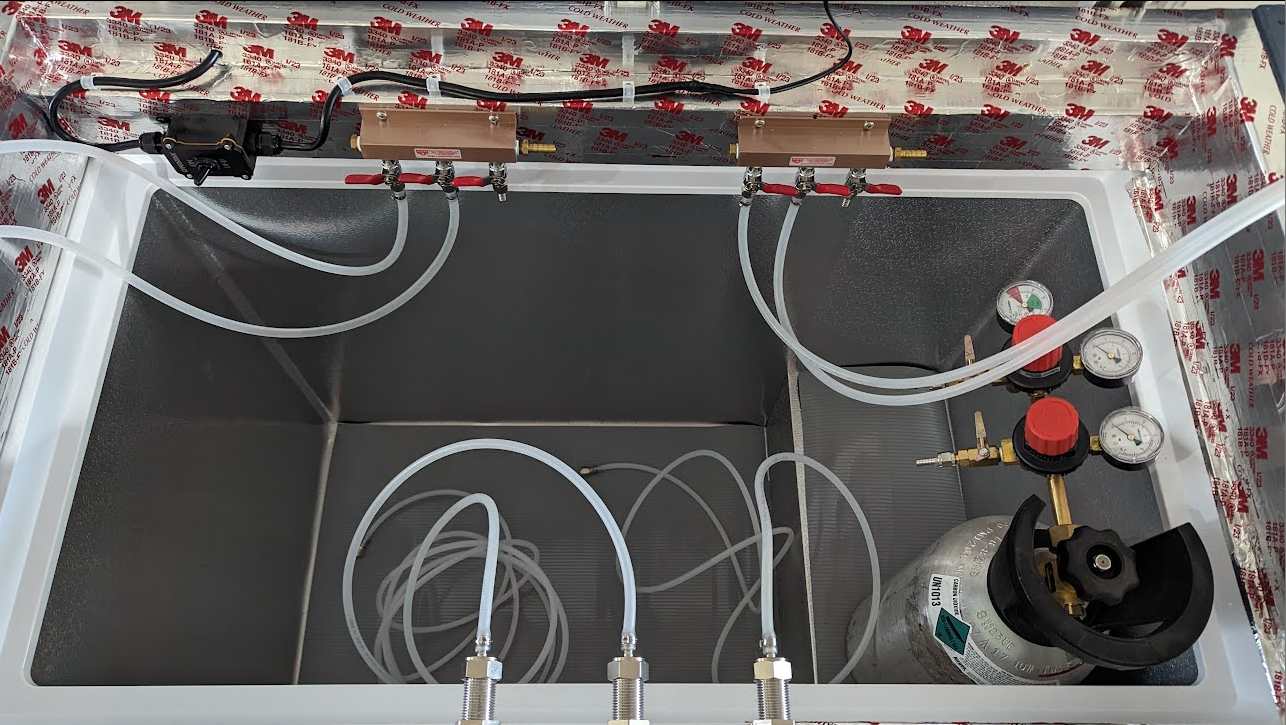

This resulted in me basically building an "exoskeleton" integrated into the collar that I would ultimately drop on top of the chest freezer prior to mounting the lid. I also wanted the new keezer to be easy to move around so I also built a dolly as a base for the chest freezer.

Even though I used wood, I opted to let my wife paint it whatever color she wanted as opposed to me staining it. I figured this was the least I could do since she "allows" me to keep my keezer in the house.

Various pics of the build process follow...

Pics of the collar prior to being integrated into the exoskeleton (more fun to say than "frame"...) and the dolly.

The Chest Freezer; I opted to buy a new one. I was able to pickup a 10.2 cubic foot Insignia from Best Buy on sale.

My old keezer was black but the new one was white. My wife often complained that it looked ugly. So I decided to surround my new one in wood. I understand that some chest freezers leverage the skin for heat dissipation so a goal was to allow at least some gap between the freezer skin and the wood I was surrounding it with.

This resulted in me basically building an "exoskeleton" integrated into the collar that I would ultimately drop on top of the chest freezer prior to mounting the lid. I also wanted the new keezer to be easy to move around so I also built a dolly as a base for the chest freezer.

Even though I used wood, I opted to let my wife paint it whatever color she wanted as opposed to me staining it. I figured this was the least I could do since she "allows" me to keep my keezer in the house.

Various pics of the build process follow...

Pics of the collar prior to being integrated into the exoskeleton (more fun to say than "frame"...) and the dolly.

Last edited: