Boerderij_Kabouter

Well-Known Member

Damn sexy willy. Well done.

Looks like your not done, a splash shield for the pump and muffin fan are missing.

That would be under the "Code Nazi" section.

As for the brass fitting, unfortunately that is part of the BCS thermistor.

The stand would have been over $1k, but I had a friend help me out with it and he kept it in the $200 range.

What?! Stainless for $200.00? Now I'm really hatin'.

Brewers Hardware offers a SS replacement...

http://www.brewershardware.com/1-4-Compression-X-1-2-MNPT-Bored-Through-fitting.html

Sorry I don't know how to resize

Anyone have opinions on gas / propane manifold placement? for convenience this one looks about perfect but I am concerned with the heat in that area (I will be using 3 banjo burners).....thoughts / suggestions?

Anyone have opinions on gas / propane manifold placement? for convenience this one looks about perfect but I am concerned with the heat in that area (I will be using 3 banjo burners).....thoughts / suggestions?

Thanks

Vince

Sorry I don't know how to resize

I would add heat shields around those burners, keep an eye on the flame preventing it from backing up below the shields or going beyond the keg skirts. You would need holes or a gap above these shields to not cause the flame to be trapped in a pocket this would blow back into the burners knocking out the flame itself. Like a propane torch when heating in a corner or pocket the blowback knocks the flame out. A hot gas line is not a worry as there's no oxygen to combust within the line, maybe a half round heat shield 12" in diameter behind each gas valve to protect the valves and plastic handles. BTY, where did you get those casters, rather slick large diameter for easy rolling over uneven cement? Looks like MoPar green like the Crazy Grape they had years ago a clean sharp looking rig.

One question, any pump priming problems with having the inlet and outlet on the bottom od the pump vs rotating it 180 degrees to remove the air pocket?

Could also be a prospector... but isn't that splitting hairs, its a DODGE and that is all that matter!!!

The prospector. That's right. Don't know why I said explorer.

Popped it's cherry yesterday. Lets just say I was very impressed

I'm very impressed as well. Can we at least get the specs to drool over?

Nice! Thanks for filling us in. I actually went and stalked your threads after posing the question, that is some really neat gear!Sure can! This is Morebeer's 2050 w/tippy dump. 26 gallon vessels, no automation, single pump. HLT on the bottom, MT on the top, and kettle right there in front. The heat rising up from the HLT on the bottom keeps the MT temps right where you want it.

Full false bottom in the MT and the kettle. HLT has a sight glass. Brew Thermometer & SS QDs on all vessels. The tippy dump rocks! Put a large trashcan underneath the shoot and dump away. Spent grain removal in .5 seconds

I built a clone of Sabcos chill wizard and can chill 21 gallons from boiling to 70 in 11 minutes all while its being oxygenated and racked into a Blichmann 27 gallon conical.

My ghetto-fabulous 100% scrap wood 3-tier system. I built this in 4 hours with wood I found in the garage attic left by the previous owner (I know, it looks like that's what I did too!).

I still need to put something under the HLT to keep it from catching fire. I've got some metal cabinet doors that I'll probably use up in that attic...

I love seeing these stands. It's what us normal people have but just don't get posted.

My ghetto-fabulous 100% scrap wood 3-tier system. I built this in 4 hours with wood I found in the garage attic left by the previous owner (I know, it looks like that's what I did too!).

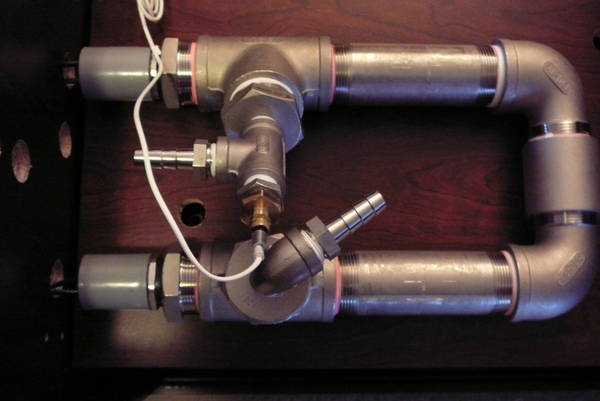

Took about 6 weeks to plan and build her, been waiting to post in here:

KILL-A-WATT 9000 Electric Brewery (100% constructed in my dining room)

15G Kettles

9000W Electric BK

9000W Electric RIMS Heater

Full Wireless BCS Control

All Stainless

TriClamp fittings

50' 1/2" OD SS Removable Chiller

RIMS:

SSRs:

Pumps:

Inside BK:

Inside MLT:

50' Chiller:

Control:

I dig the two tone!!This is the updated version, almost done!!!!!

https://www.homebrewtalk.com/f51/new-brew-stand-need-burner-help-165599/

its not simple but my pics are on this link,cheers!!

its not simple but my pics are on this link,cheers!!

its not simple but my pics are on this link,cheers!!

http://www.flickr.com/photos/49451208@N05/

amazing this entire brewery is powered by 2 cell phone chargers

This is the updated version, almost done!!!!!

https://www.homebrewtalk.com/f51/new-brew-stand-need-burner-help-165599/

Enter your email address to join: