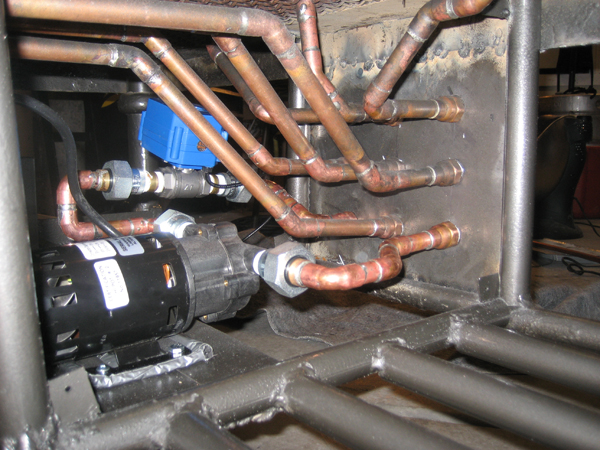

Well the time has finally come. I can add my own rig to the thread. I finished most everything on the rig tonight. It is functionally done. I can do wet tests this weekend hopefully and then next week sometime. Brew my first beer. I think I am going to do a dunkel. If you want to see more pictures of the build. I have link to the thread in my signature.......Well here it is:

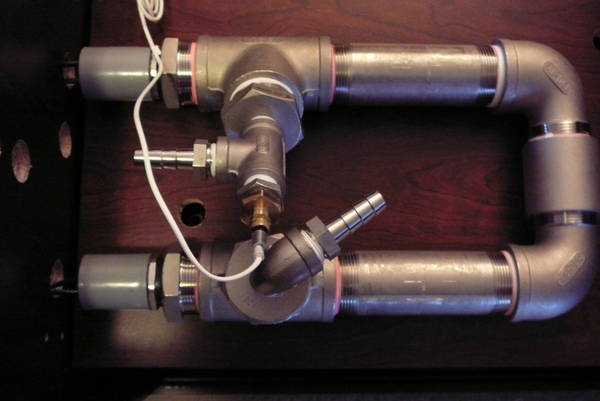

All electric, PID and PWM controlled. 5500w BK and 1500w heat exchanger.

All electric, PID and PWM controlled. 5500w BK and 1500w heat exchanger.