You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Safe Kitchen BIAB Pulley

- Thread starter SeeRoe

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Yellowirenut

Well-Known Member

- Joined

- Feb 9, 2013

- Messages

- 465

- Reaction score

- 75

you better hit a stud. That's a lot of weight..

Think hmm would I hang a sex swing from there?

Think hmm would I hang a sex swing from there?

Dunno, but I'd be careful about permanently attaching something to a joist. Make sure it's wife approved, and sturdy enough to hold what you want it to hold.

I would suggest a hook inside the cabinet above the stove. Drill through the cabinet back and into a wall stud. Or perhaps directly above the cabinets if you have an open soffit, and into a wall stud. Both are out of view, SWMBO approved locations.

BlueHouseBrewhaus

Well-Known Member

I had handy pot hangers already in my kitchen. No complaints from my wife since they were already there.

pennengr

Well-Known Member

I use a swivel hook designed for hanging plants. The hook part is removable - just leaves an inconspicuous flat metal disk on the ceiling.

pricelessbrewing

Brewer's Friend Software Manager

I use a swivel hook designed for hanging plants. The hook part is removable - just leaves an inconspicuous flat metal disk on the ceiling.

That's exactly what I've been thinking about, buy haven't been able to locate. Would you be able to find a link for one?

I got one of these from Harbor Freight. Not the best quality, but does the job of lifting a heavy load for a very cheap price. I rigged mine up to lift a Grainfather basket in the basement with an eye-hook fastened to an overhead floor joist.

http://www.harborfreight.com/gambrel-and-pulley-hoist-99758.html

http://www.harborfreight.com/gambrel-and-pulley-hoist-99758.html

- Joined

- Mar 12, 2007

- Messages

- 6,841

- Reaction score

- 857

Good wife. Good joists.Dunno, but I'd be careful about permanently attaching something to a joist. Make sure it's wife approved, and sturdy enough to hold what you want it to hold.

edit: actually hit three joists on 24" centers

pennengr

Well-Known Member

That's exactly what I've been thinking about, buy haven't been able to locate. Would you be able to find a link for one?

This is what I have: http://www.homedepot.com/p/Cobra-Anchors-90-lb-White-Steel-Ceiling-Swivel-Driller-Hook-59908/202259541

I screwed it directly into a joist.

I had handy pot hangers already in my kitchen. No complaints from my wife since they were already there.

Not to be that guy... but I'm concerned that you are putting stresses on the sides of your eye screws, where they are made to support loads in (this case) the down direction. I think you would be better served puttin another bolt directly above where you want your bag, or hanging a bar or something, then hanging the pulley off of that. Like Pennengr has. Otherwise, you risk damaging the wood by pulling the eye screws from the side, and having them loosen.

Although, I enjoy the ingenuity.

Not to be that guy... but I'm concerned that you are putting stresses on the sides of your eye screws, where they are made to support loads in (this case) the down direction.

I agree, the eye screws are being side loaded here when they are made to support loads in the down direction. BUT these appear to be 3/8" eye screws (the pulley rope is 1/4"), and would likely hold around 1000 lbs before failing???(just a guess). I seriously doubt a 10-20 lb grain bill is a concern, side loaded or not.

- Joined

- Mar 12, 2007

- Messages

- 6,841

- Reaction score

- 857

Probably double that easy when wet. And I may be remembering my physics wrong, but when you're pulling down on the rope, don't you double the load at the fulcrum?I seriously doubt a 10-20 lb grain bill is a concern, side loaded or not.

I'm more concerned he might damage his wife's glass top electric stove lol. Homebrewing can be hell on a kitchen stove.

This is a silly discussion IMHO, you could probably hoist a V8 out of a Ford truck with the rig in the picture...not that I would try it. The eye screws are also ductile, they would bend quite a bit prior to breaking and give indication of potential failure. This was called "run time" by one of my professors years ago. lol

How large a batch could he possibly be doing on the stove pictured, 5 gallon tops?

And yes, a single eye screw above the kettle would be more structurally correct, but if you read the post, the guy was working with the hardware that was already in place. I doubt his wife would appreciate an empty eye bolt above the stove in "her" kitchen.

I'm actually quite impressed that he used cable thimbles and double cable clamps. I would also think the user proof loaded his work by giving it a hefty tug prior to hanging a grain bag several times less weight.

This is a silly discussion IMHO, you could probably hoist a V8 out of a Ford truck with the rig in the picture...not that I would try it. The eye screws are also ductile, they would bend quite a bit prior to breaking and give indication of potential failure. This was called "run time" by one of my professors years ago. lol

How large a batch could he possibly be doing on the stove pictured, 5 gallon tops?

And yes, a single eye screw above the kettle would be more structurally correct, but if you read the post, the guy was working with the hardware that was already in place. I doubt his wife would appreciate an empty eye bolt above the stove in "her" kitchen.

I'm actually quite impressed that he used cable thimbles and double cable clamps. I would also think the user proof loaded his work by giving it a hefty tug prior to hanging a grain bag several times less weight.

I agree, this is somewhat silly discussion. This type of 3/8 eye-lag has a safe weight range of 125-200 pounds (depending on who made it) with a 4:1 safety margin (meaning the failure weight is 500+pounds).

(meaning the failure weight is 500+pounds).

Times 2 in this application with 2 eye screws....1000+ pounds lol

actech

Well-Known Member

Good wife. Good joists.

edit: actually hit three joists on 24" centers

How big is your pot? I've been using induction with my 3 gallon but want bigger. just wasnt sure it would work with induction

- Joined

- Mar 12, 2007

- Messages

- 6,841

- Reaction score

- 857

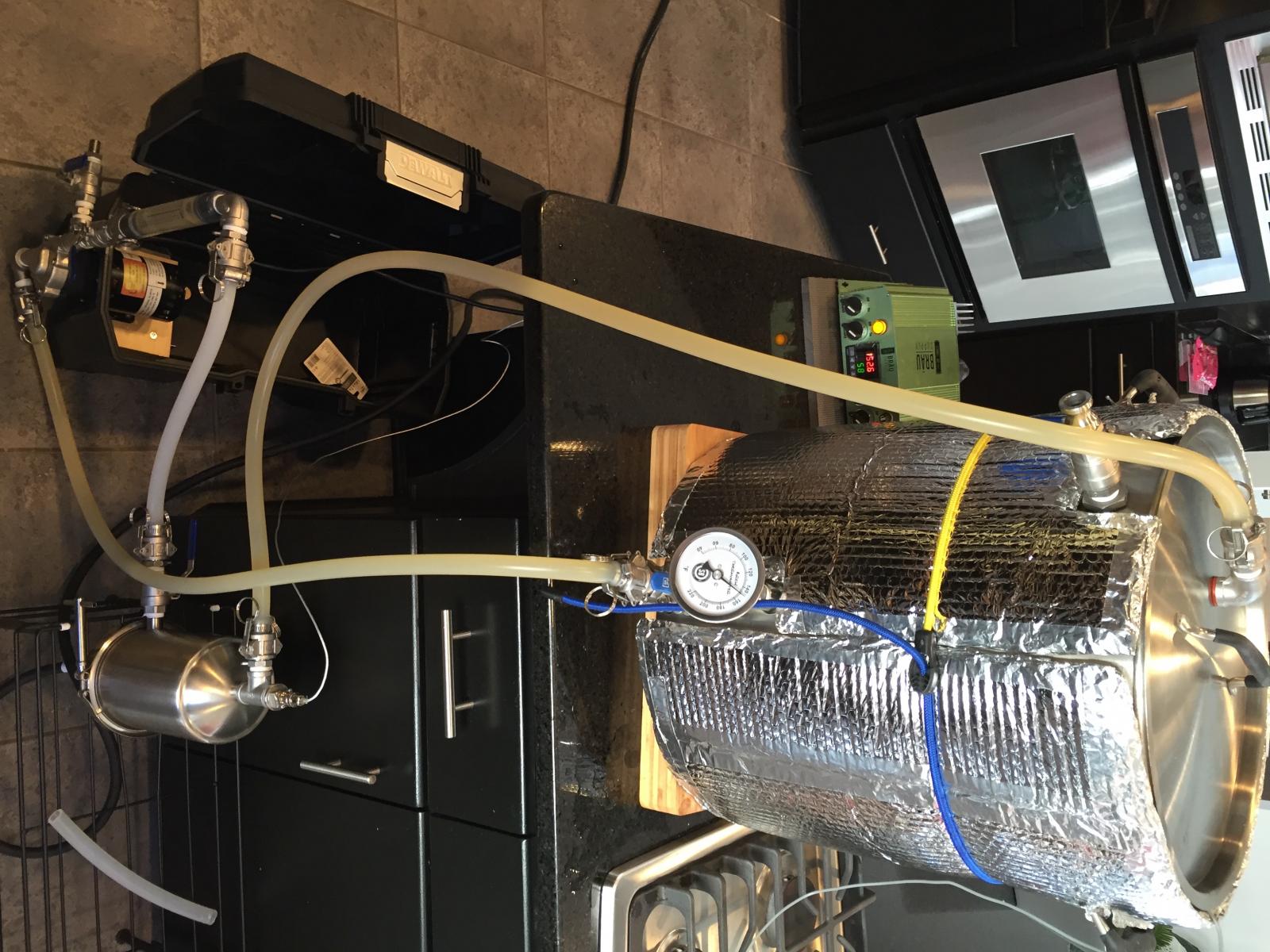

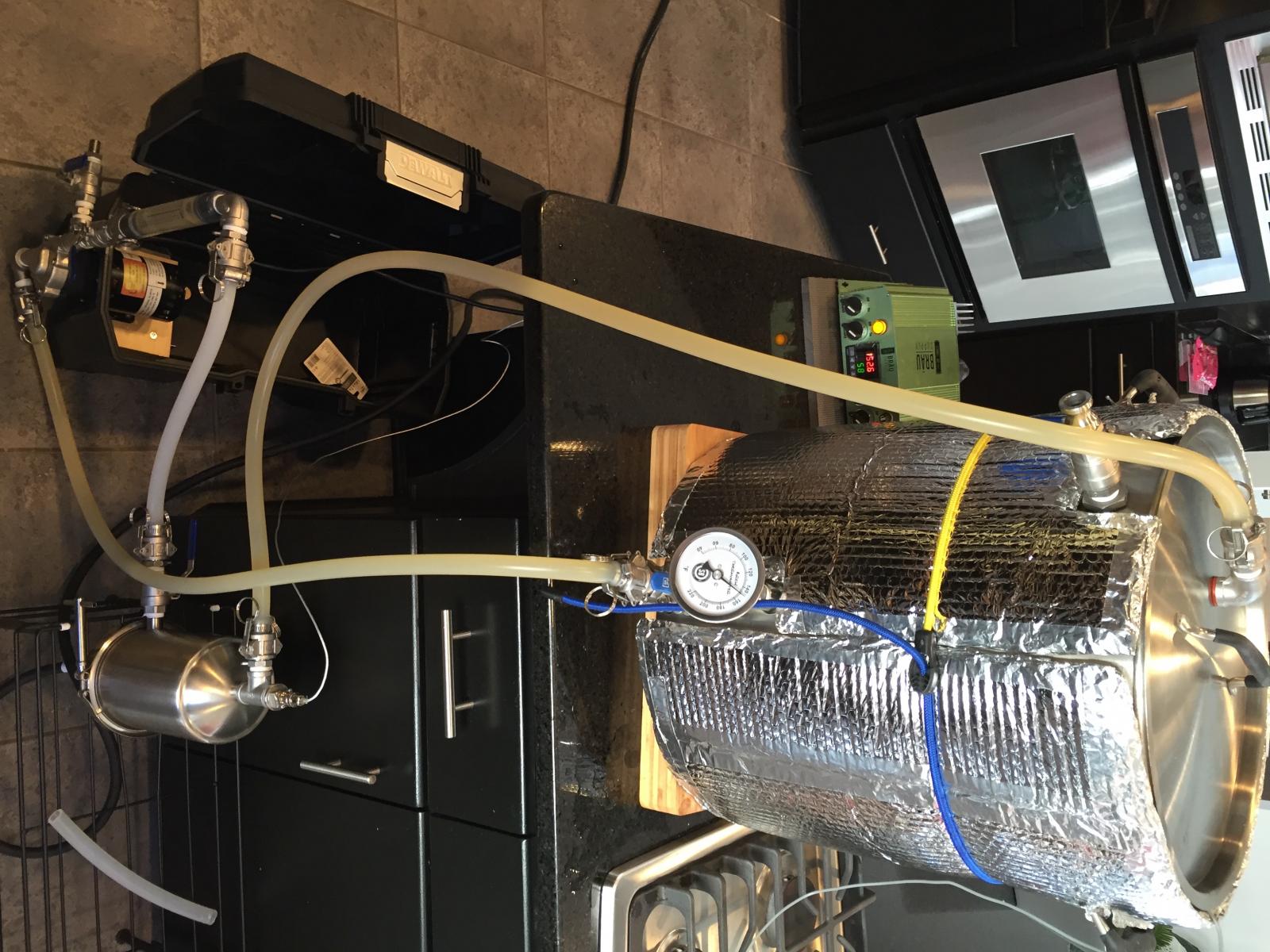

15.5 gallon (with over 14 coming to a boil here) . . .How big is your pot? I've been using induction with my 3 gallon but want bigger. just wasnt sure it would work with induction

BlueHouseBrewhaus

Well-Known Member

I'm more concerned he might damage his wife's glass top electric stove lol. Homebrewing can be hell on a kitchen stove.

This is a silly discussion IMHO, you could probably hoist a V8 out of a Ford truck with the rig in the picture...not that I would try it. The eye screws are also ductile, they would bend quite a bit prior to breaking and give indication of potential failure. This was called "run time" by one of my professors years ago. lol

How large a batch could he possibly be doing on the stove pictured, 5 gallon tops?

And yes, a single eye screw above the kettle would be more structurally correct, but if you read the post, the guy was working with the hardware that was already in place. I doubt his wife would appreciate an empty eye bolt above the stove in "her" kitchen.

I'm actually quite impressed that he used cable thimbles and double cable clamps. I would also think the user proof loaded his work by giving it a hefty tug prior to hanging a grain bag several times less weight.

I'm loving this! As you may have guessed, these are all the same issues and questions my wife brought up when I first proposed this rig.

First, yes, they are 3/8" eye hooks. To assuage my wife's fears, I actually brushed off my engineering degree and cranked through the calculations to figure the vertical and horizontal components of the forces on the eye hooks and the axial forces on the cable.

My bag sits in the basket and my system maxes out at about 16 lbs of grain. I figured about 0.2 gal/lb "short term" water absorption since it takes a while for the grain to drain as I hoist the basket. Plus my modified BIAB method sparge system involves suspending as much as 1.5 gal of sparge water nested in the top of the basket.

So, we have:

16 lbs grain

0.2 x 16 = 3.2 gal water absorbed x 8.34 lbs/gal = 26.7 lbs

1.5 gal sparge x 8.34 = 12.5 lbs

For a total of 55.2 lbs. This pretty conservative since a good deal of the wort will have already drained from the basket before I put my sparge water in the top.

I don't still have my calculations and vector diagrams from when I did this exercise over 3 years ago but, suffice it to say, I had a safety margin at least 4:1 or more and the limiting factor was a tossup between the strength of the carabiners that clip to the eyes and the strength of the wood. The double clamps on the cables were a "belt and suspenders" addition when my wife pointed out that even if nothing broke, "those clamps could slip, ya know". Over 50 brews later and there is no deflection or deformation in the eyes, cable or wood.

Where else but here could I could I geek out on math and brewing at the same time. Gotta love this site

P.S. With my 9 gal "tallboy" BK, I can boil 7 gal on my stove. I think the smaller base helps concentrate the heat. No sweating or freezing outside and it's right next to the sink.

Whew, wipes brow....I can finally get some sleep.

Nice work! Your calculations assume you extract nothing from the grain, that would kinda suck lol, 0% efficiency.

J/k

Even with or without the best calculations, a proof load is a good idea.

Heard an interesting story recently, during the recent bridge rehab on the Pulaski Skyway in NJ, the NJDOT performed proof loading or pull out testing on the anchor bolts for the bridge safety railing and many of the bolts were failing. It was determined that the workers were only threading the anchors a few threads into the inserts in the pre cast bridge deck prior to pouring the concrete for the bridge sidewalk omg! The contractor had to remove approx 5000' of bridge sidewalk $$$ and redo the threaded anchors. The job is plagued with problems and is anticipated to lose $30 million on a $100 million contract.

The contractor is CCA, or China Civil America which is owned or backed by the Chinese government, oh well expensive lesson sometimes life's a birch lol.

Nice work! Your calculations assume you extract nothing from the grain, that would kinda suck lol, 0% efficiency.

J/k

Even with or without the best calculations, a proof load is a good idea.

Heard an interesting story recently, during the recent bridge rehab on the Pulaski Skyway in NJ, the NJDOT performed proof loading or pull out testing on the anchor bolts for the bridge safety railing and many of the bolts were failing. It was determined that the workers were only threading the anchors a few threads into the inserts in the pre cast bridge deck prior to pouring the concrete for the bridge sidewalk omg! The contractor had to remove approx 5000' of bridge sidewalk $$$ and redo the threaded anchors. The job is plagued with problems and is anticipated to lose $30 million on a $100 million contract.

The contractor is CCA, or China Civil America which is owned or backed by the Chinese government, oh well expensive lesson sometimes life's a birch lol.

BlueHouseBrewhaus

Well-Known Member

Whew, wipes brow....I can finally get some sleep.

Nice work! Your calculations assume you extract nothing from the grain, that would kinda suck lol, 0% efficiency.

J/k

Even with or without the best calculations, a proof load is a good idea.

Heard an interesting story recently, during the recent bridge rehab on the Pulaski Skyway in NJ, the NJDOT performed proof loading or pull out testing on the anchor bolts for the bridge safety railing and many of the bolts were failing. It was determined that the workers were only threading the anchors a few threads into the inserts in the pre cast bridge deck prior to pouring the concrete for the bridge sidewalk omg! The contractor had to remove approx 5000' of bridge sidewalk $$$ and redo the threaded anchors. The job is plagued with problems and is anticipated to lose $30 million on a $100 million contract.

The contractor is CCA, or China Civil America which is owned or backed by the Chinese government, oh well expensive lesson sometimes life's a birch lol.

Oh, man! Now I have to redo my calcs to figure in grain extraction

We had a similar bridge issue in CT years ago. There was an elevated highway ramp being built supported by cantilevered T-shaped columns. Before the ramp opened, they discovered the arms of the T were developing cracks. Turns out the contractor had read the plans incorrectly and neglected to install more than half of the rebar in the concrete. They had to retrofit all the columns. Can't even blame that one on China. Just stupidity.

OK. We now return you to your regularly scheduled brewing forum

pennengr

Well-Known Member

So I did my third kitchen BIAB/RIMS today (before I was all stovetop). Here are a couple of photos of my rig and my pulley. (What's the trick to making these photos show up properly BTW? They were laying on their left, so i rotated them 90 degrees and now they're laying on their right...)

My concern was more about the stress from the side loosening the hooks in the wood, not about the metal failing. I don't think I was clear in my post, and perhaps even if I was, it's probably not a significant concern. But with it being over the stove, subject to steam, it seemed something to think about, especially if someone is copying this setup.

Sounds like BB is on top of it however, the engineering calcs is a nice touch. You're paying attention, which is the important part.

Penngar, we can't see your pics!

Sounds like BB is on top of it however, the engineering calcs is a nice touch. You're paying attention, which is the important part.

Penngar, we can't see your pics!

pennengr

Well-Known Member

My concern was more about the stress from the side loosening the hooks in the wood, not about the metal failing. I don't think I was clear in my post, and perhaps even if I was, it's probably not a significant concern. But with it being over the stove, subject to steam, it seemed something to think about, especially if someone is copying this setup.

Sounds like BB is on top of it however, the engineering calcs is a nice touch. You're paying attention, which is the important part.

Penngar, we can't see your pics!

Hmm - how about this time...

ParanoidAndroid

Well-Known Member

15.5 gallon (with over 14 coming to a boil here) . . .

What kind of insulation is that? Looks sleek. Im looking to update my Reflectix on my mash tun. Looking into a Nitrile type material.

My concern was more about the stress from the side loosening the hooks in the wood, not about the metal failing. I don't think I was clear in my post, and perhaps even if I was, it's probably not a significant concern. But with it being over the stove, subject to steam, it seemed something to think about, especially if someone is copying this setup.

Sounds like BB is on top of it however, the engineering calcs is a nice touch. You're paying attention, which is the important part.

Valid concern, IMHO. He did say he calculated vertical and horizontal forces, and I would note that they are substantial. With the angle in the picture (Slightly more than 150 degrees), the force on EACH side is TWICE the weight of the bucket! For his case, it probably is over engineered enough, but this is is a geometry that should raise red flags for anyone copying it!

Similar threads

- Poll

- Replies

- 69

- Views

- 3K

- Replies

- 5

- Views

- 413