iijakii

Well-Known Member

Wanting to see if this is the most logical way, or if anyone has suggestions I haven't thought of.

I'm doing a 2x 120v eHERMS build. Originally wasn't wanting to go HERMS due to budget, but dat bling. So I've made some design changes I feel won't be adverse and will let me keep it on the budget SWMBO won't castrate me over.

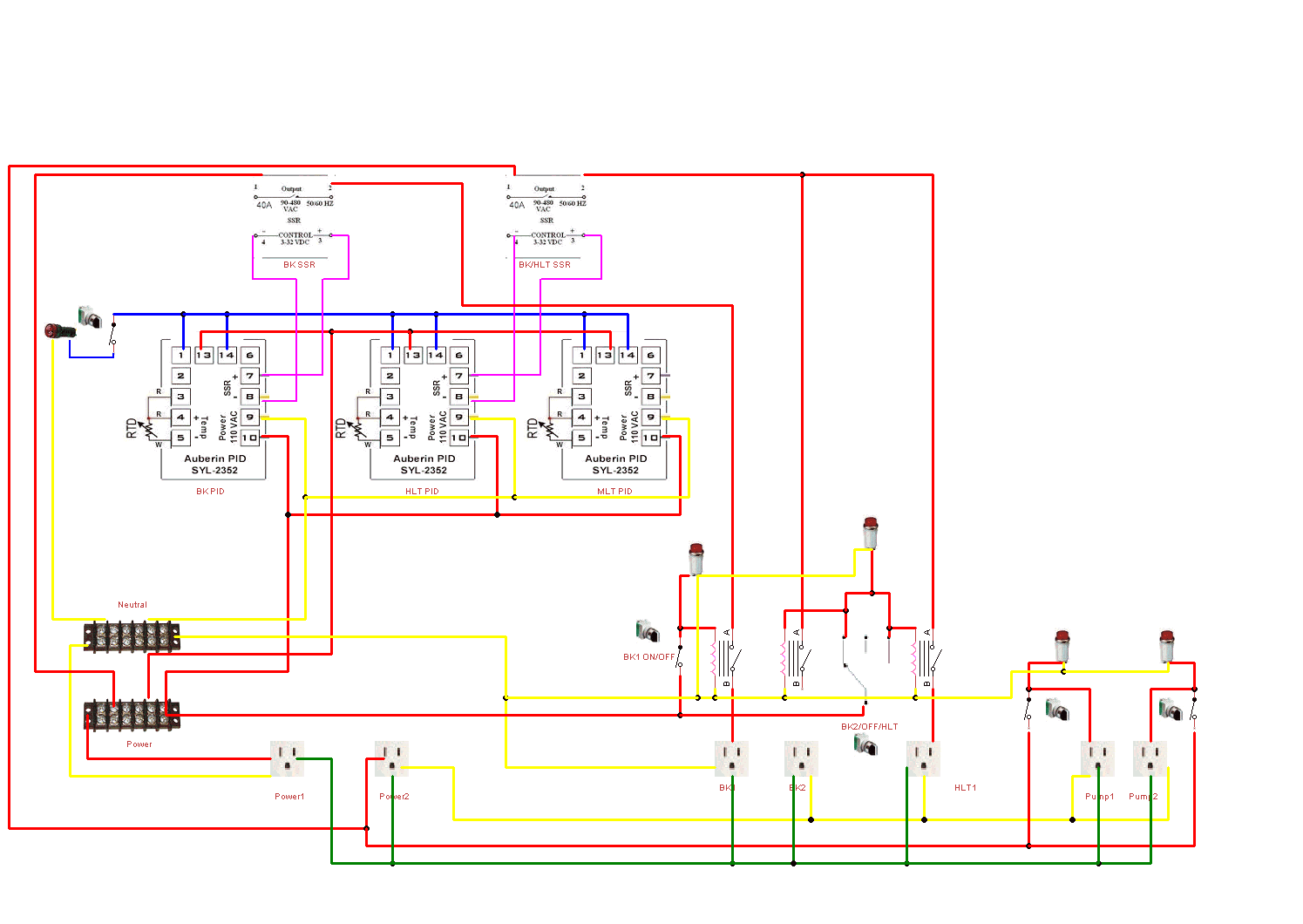

2x PIDs. One probe to the BK (heating up strike water), one probe to either the HLT or MT. Haven't decided on this yet. I'm not sure I want to just do the HERMS coil output and not have an overall temp readout of my mash. Although that might be unnecessary since the temps would likely be the same as long as flow isn't bad. Still, I know how much delta can happen in a SS mash tun. I've heard of cons to using the overall mash temp to drive HLT probe. Would also make the initial heating of water tricky.

I'd have two elements in the BK and one in the HLT, capacity to only run two. I was thinking on the second outlet I'd just unplug it from the HLT and plug in the second BK element when it's time to boil. Then I'd have have the second element's SSR coil on a switch between the two PIDs. That way when I have it plugged into the HLT it's getting cycled by the Mash PID. Then when I go to boil I switch it back to the BK's PID and run the two elements in series manual mode.

I don't see any cons to this, but I'm not sure if i'm straddling two worlds here for not much gain, and need to either go full 3 PID or should just go super budget single.

I'm doing a 2x 120v eHERMS build. Originally wasn't wanting to go HERMS due to budget, but dat bling. So I've made some design changes I feel won't be adverse and will let me keep it on the budget SWMBO won't castrate me over.

2x PIDs. One probe to the BK (heating up strike water), one probe to either the HLT or MT. Haven't decided on this yet. I'm not sure I want to just do the HERMS coil output and not have an overall temp readout of my mash. Although that might be unnecessary since the temps would likely be the same as long as flow isn't bad. Still, I know how much delta can happen in a SS mash tun. I've heard of cons to using the overall mash temp to drive HLT probe. Would also make the initial heating of water tricky.

I'd have two elements in the BK and one in the HLT, capacity to only run two. I was thinking on the second outlet I'd just unplug it from the HLT and plug in the second BK element when it's time to boil. Then I'd have have the second element's SSR coil on a switch between the two PIDs. That way when I have it plugged into the HLT it's getting cycled by the Mash PID. Then when I go to boil I switch it back to the BK's PID and run the two elements in series manual mode.

I don't see any cons to this, but I'm not sure if i'm straddling two worlds here for not much gain, and need to either go full 3 PID or should just go super budget single.