You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

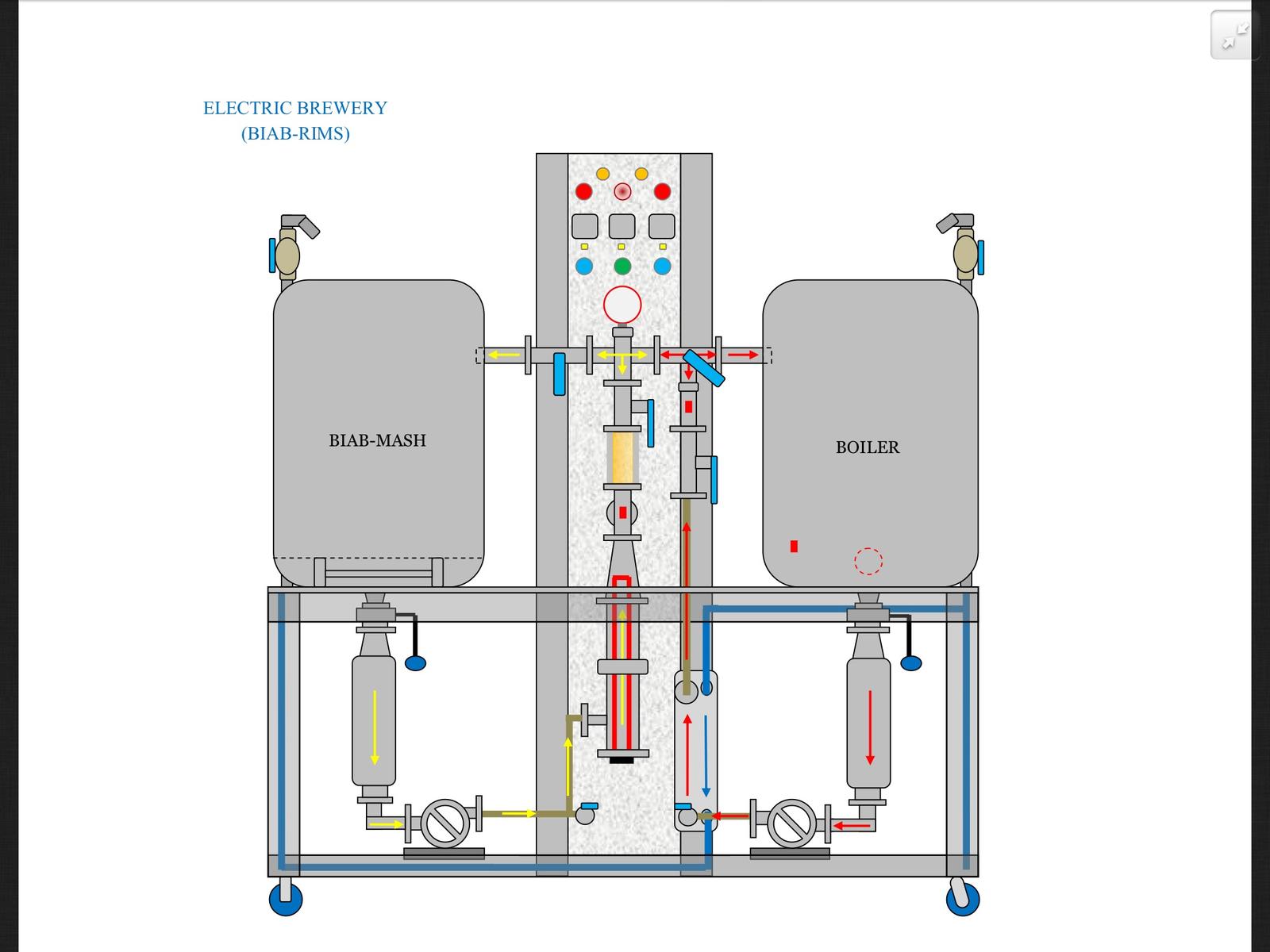

Purpose Built-No Sparge Brewery

- Thread starter Brew52

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Ok Guy's, So I stayed up late one night recently just starring at my system and all the modifications I would need to do to change over to HERMS and I thought to myself, maybe I over reacted to the first brew day incident with the scorched batch. After all there are a lot of Brewers on this forum using RIMS with great results and really I just had some design issues other than that things went well so call me crazy but I am going to switch back to the original system pic at the start of this thread and give RIMS a second chance only this time I will use a BIAB Bag from the start and will not use the strainer screens below each kettle and I will use the 2000watt/240 volt element that PJ has suggested in several of his post. Since I was taking things apart anyway, I decided to install a ball valve just below the dial thermometer in the middle so now I can heat my strike water quickly in the boil kettle and pump it directly into the Mash Tun. The more I look at it, the more I think it really is a pretty good design and I am committed to getting it to work properly. I will attach a drawing of the final design when I get it to work. I just updated my iPad to IOS8 and now I can't attach photos to this forum for some reason.

- Joined

- Aug 1, 2008

- Messages

- 30

- Reaction score

- 1

I'm happy to hear you haven't abandoned your initial plan yet. The system looks to good to start making major modifications. You might have to take some precautionary measures to ensure your flow is well established prior to engaging the RIMS element but I have a hard time believing so many people would adopt RIMS systems if they didn't produce good results.

Keep things in perspective, you're conducting your first engineering runs in an effort to best define your process. The "commercial batches" will follow. I'm looking forward to see how things progress.

Keep things in perspective, you're conducting your first engineering runs in an effort to best define your process. The "commercial batches" will follow. I'm looking forward to see how things progress.

Leadpencil

Well-Known Member

Nice looking rig. I am going to be doing something similar but at 1 barrel size. Where did you get the filters from?

Nice looking rig. I am going to be doing something similar but at 1 barrel size. Where did you get the filters from?

Thank you. I got them from Brewers Hardware $129.00 each, but if you read my full thread you will see that I did not have very good luck using them for my purpose, but I'm sure they work great for straining whole hops. Good luck with your rig.

Between these 2 current configurations, HERMS without a doubt. From someone learning to fire and operate steam powered engines, all the way up to railroad locomotives, your RIMS design without a pressure relief device between the RIMS chamber and 1st downstream valve scares the heck out of me. A few design changes on the bottom end could eliminate the need for the 2 valves between the RIMS chamber and the mashtun.

Lumpyyyyy

Well-Known Member

Little bit OT but what software are you using to draw up these schematics? Looks like Visio but appears to be on your iPad.

Sent from my iPhone using Home Brew

Sent from my iPhone using Home Brew

Little bit OT but what software are you using to draw up these schematics? Looks like Visio but appears to be on your iPad.

Sent from my iPhone using Home Brew

Are you sitting down? Good. I actually just used Microsoft Word on Windows 7 and then saved as: PDF

Between these 2 current configurations, HERMS without a doubt. From someone learning to fire and operate steam powered engines, all the way up to railroad locomotives, your RIMS design without a pressure relief device between the RIMS chamber and 1st downstream valve scares the heck out of me. A few design changes on the bottom end could eliminate the need for the 2 valves between the RIMS chamber and the mashtun.

I'm curious about what you said. If I were to use a pressure relief valve between the RIMS and valve, what psi would you suggest and can a relief valve be mounted horizontal or only vertically? Thank you.

Thank you. I got them from Brewers Hardware $129.00 each, but if you read my full thread you will see that I did not have very good luck using them for my purpose, but I'm sure they work great for straining whole hops. Good luck with your rig.

I use the same filter when pumping wort out of the brew kettle and into the chiller. It works great BUT I whirlpool it first and leave half the trub in the kettle.

A pressure relief valve capable of venting liquid would be pricey and you have to consider how to contain or direct the blowoff. Personally I would vent the RIMS chamber to atmosphere through the MT return port - no valves in between. That means separating the MT side of the system from the BK side, except across the bottom. Move both flow control valves to connect directly to the output port on each pump, respectively.

Now you have to address your desire to be able to back flush the heat exchanger. Drop the 3-way valve from the BT return port to the HE output port. The center leg of that 3-way would connect to the T with the drain valve on the MT side. The 2nd 3-way would connect to the input port on the HE, with 1 of its ends connected to the input port on the RIMS chamber and the other end being fed by the flow control valve from the BK pump. The downside to this particular configuration is that the mash recirculation would always backfeed through the HE. You could introduce grain particles into the HE. With another 3-way valve or 2 you could recirculate the mash directly to the RIMS and only backfeed the HE when in cleaning mode.

Now you have to address your desire to be able to back flush the heat exchanger. Drop the 3-way valve from the BT return port to the HE output port. The center leg of that 3-way would connect to the T with the drain valve on the MT side. The 2nd 3-way would connect to the input port on the HE, with 1 of its ends connected to the input port on the RIMS chamber and the other end being fed by the flow control valve from the BK pump. The downside to this particular configuration is that the mash recirculation would always backfeed through the HE. You could introduce grain particles into the HE. With another 3-way valve or 2 you could recirculate the mash directly to the RIMS and only backfeed the HE when in cleaning mode.

Alt,

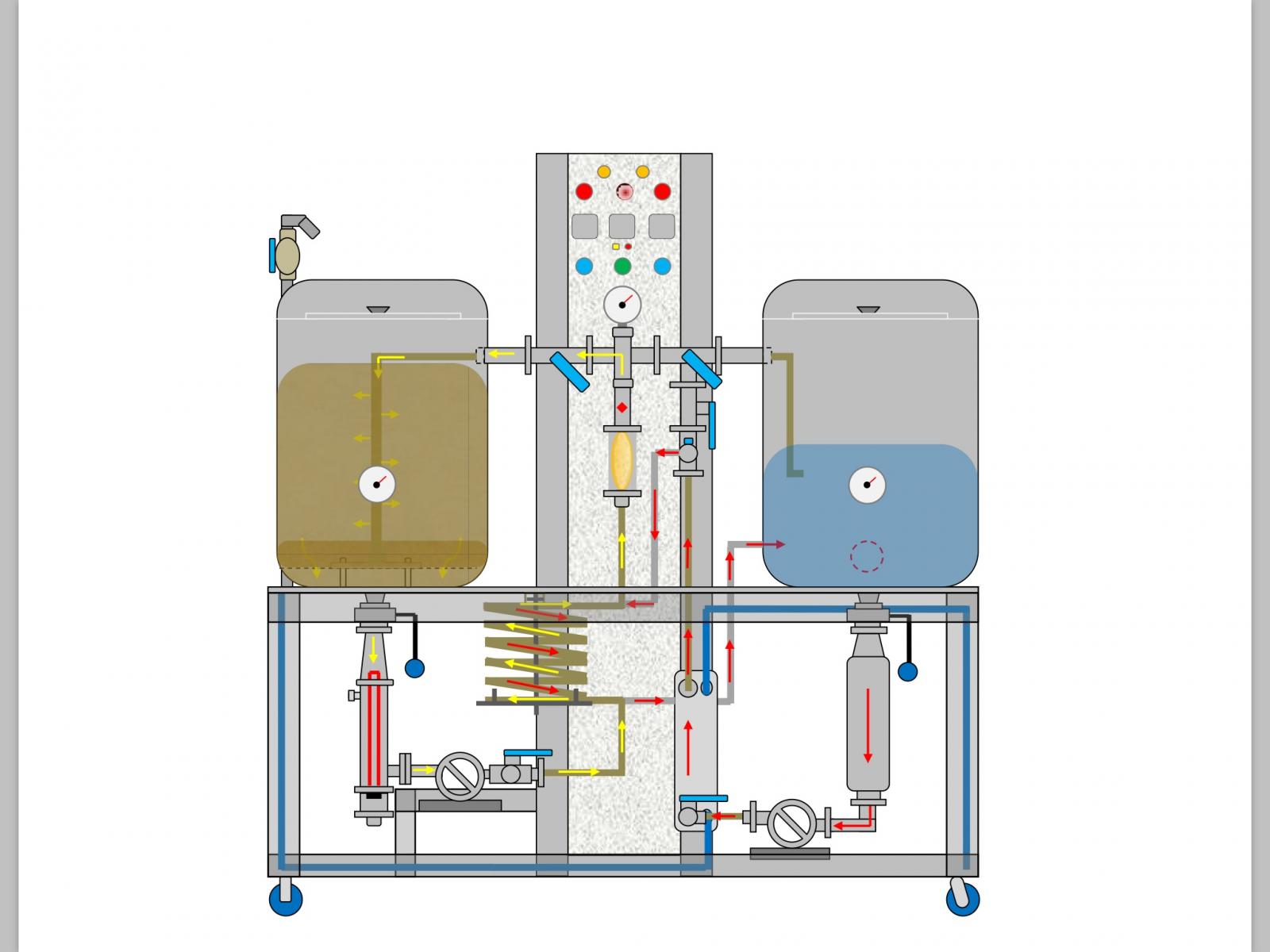

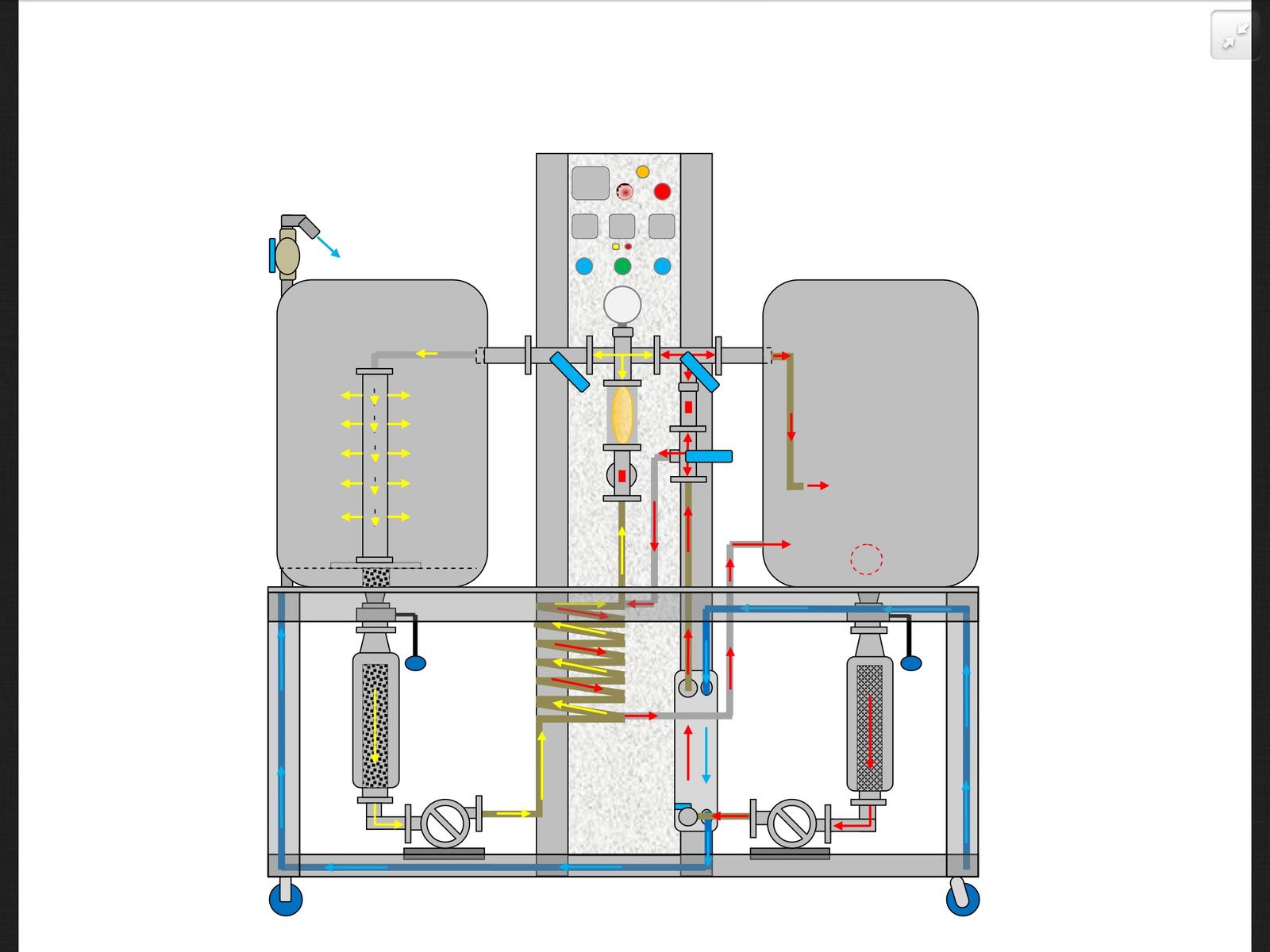

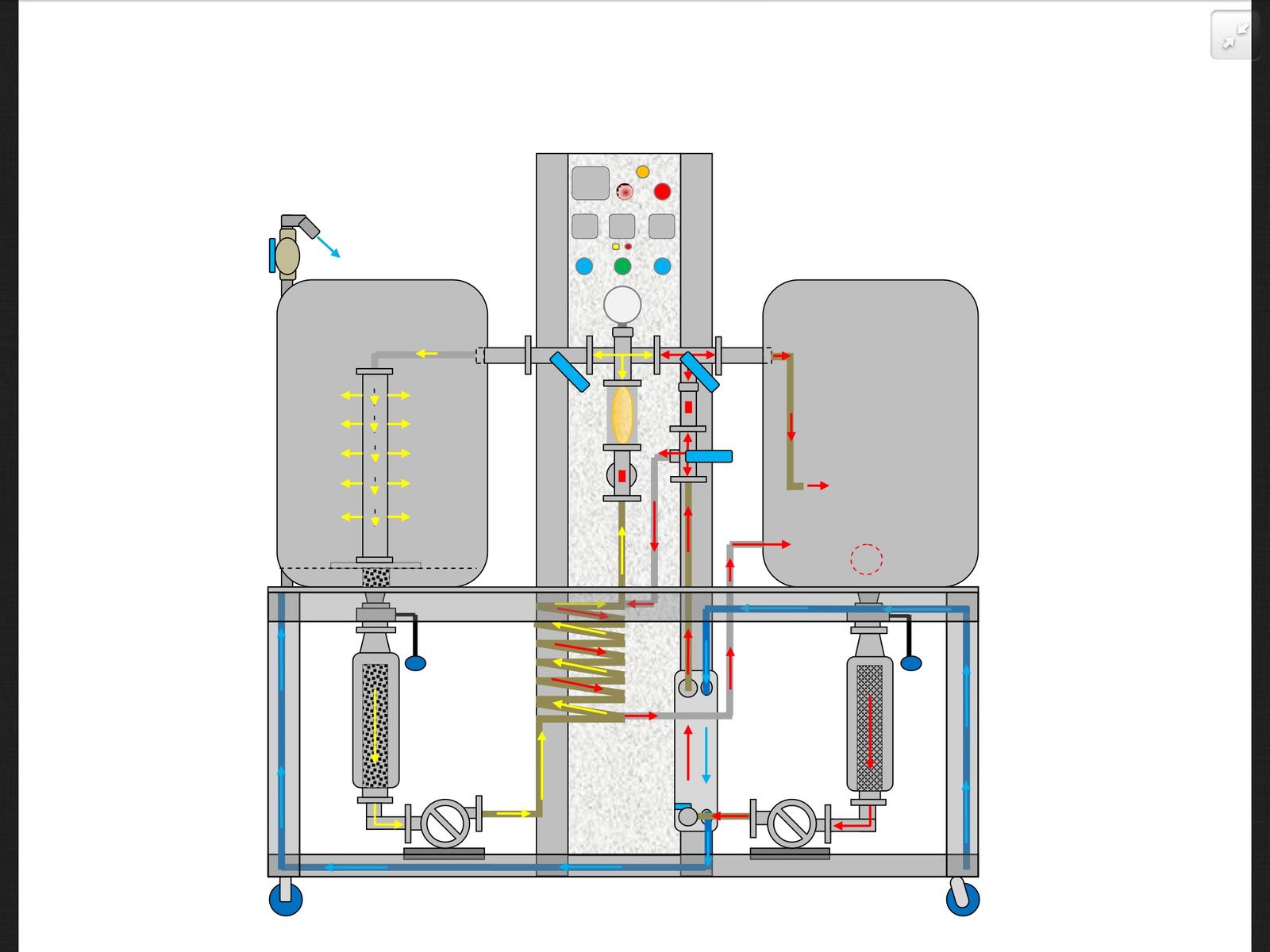

Thanks for your response. After much debate (mainly) in my own mind and looking at the Pros and Cons of RIMS vs HERMS and with approval from SWHMBO to allow for another $300.00, I have made my final decision to go with the "External" HERMS design and using only the 5500watt element in the BK as the sole source of heat. I will use the Chillzilla for HERMS coil and recirculate using both pumps at the same time when Mashing. Due to financial constraints right now and the approaching Holiday's it will most likely be Spring before I actually plug in the Brewery again. Since I run the boil in Manual Mode, I decided to remove the RTD from the back of the boil kettle and use that port as the Return port for the hot water that will recirculate through the coil. The PID that I originally used for the RIMS Tube will now be used as a digital thermometer only and will show me the temperature of the wort as it exits the plate chiller. Here is the latest (and hopefully) Last drawing of my design change. :cross:

Thanks for your response. After much debate (mainly) in my own mind and looking at the Pros and Cons of RIMS vs HERMS and with approval from SWHMBO to allow for another $300.00, I have made my final decision to go with the "External" HERMS design and using only the 5500watt element in the BK as the sole source of heat. I will use the Chillzilla for HERMS coil and recirculate using both pumps at the same time when Mashing. Due to financial constraints right now and the approaching Holiday's it will most likely be Spring before I actually plug in the Brewery again. Since I run the boil in Manual Mode, I decided to remove the RTD from the back of the boil kettle and use that port as the Return port for the hot water that will recirculate through the coil. The PID that I originally used for the RIMS Tube will now be used as a digital thermometer only and will show me the temperature of the wort as it exits the plate chiller. Here is the latest (and hopefully) Last drawing of my design change. :cross:

By the way, I have been remiss in not stating that I am totally envious of what you've assembled! :rockin:

By the way, I have been remiss in not stating that I am totally envious of what you've assembled! :rockin:

Thank you. The sad part is that I have invested close to $4,000.00 over a 3 year period making this "prototype" and now that it is pretty much all done and with the tremendous amount of knowledge I have acquired and the brew supply websites that I have visited, I figure I could build this entire system for about $2,000.00 (excluding) the in-line strainers which I have discovered really are not needed at all. I'm happy to share with everyone so if someone wants to build one and tweak the design, they won't need to go through everything I went through. Cheers!

I hope I'm not out of line if I make a few comments here. I'm not an expert, but at the same time I've messed with a few brew systems in my time. Maybe something I say will help. I'd hate to see you spend a bunch more time and money chasing issues that might be easily solved.

First off, you aren't having a RIMS problem so much as a circulation problem. Your RIMS setup would probably work fine if you solved the circulation problem, or could be tweaked to be so.

Any grain bed, no matter how its set up is going to flow a ton of fines in the first circulation or whenever its disturbed. Its just a fact of life. No matter what filter you put under the mash vessel is going to get plugged, if its acting as a filter at all. The best advice I can give here is to probably do without the filter under the MLT and your system will work fine. Just replace it with a piece of pipe. I'm not sure why you feel you need a filter there in the first place. If you recirculate the wort for any length of time the bed will begin to act as a filter and it will run crystal clear sooner or later.

Ditto with hops filters off the boil kettle. I'm all for keeping hops out of the fermenter, but that hops filter doesn't have enough area to filter everything coming out of the brew kettle. None of them do. They are designed to catch the odd leftover hop, that sort of thing, not run recirculating wort through, especially non whirpooled recirculating wort.

So my best advice would be to drop both filters and see where that gets you. Run a couple batches like that and see how they come out.

RIMS versus HERMS.

You discovered the drawback of RIMS, that being scorched wort. It isn't a problem if you keep the power low and the flow high, but if you don't watch it closely, you can wreck the batch, as you learned. Even worse than wrecking batches is making batches that have a subtle burnt or dark flavor and not realizing it or not being able to get rid of it.

HERMS has a different problem in that generally the heat exchange to the wort is slow. You'll never scorch the wort, but it takes a long time to do step mashes. This is usually because the delta T of the heating water is low (mash at 150ish, water at 170F if its going to be sparge water), flow rates are low, etc. This is why people direct fire MLTs.

Direct firing an MLT has its place. You can still scorch wort, but its got way more heating area than a RIMS element. Just compare the surface area of the bottom of an MLT with the surface area of a RIMS element. With direct firing you can get a decent amount of heat into the mash and yet not scorch it. The price for this is having a burner under the MLT, something which the eBrew guys want to avoid. An alternative would be to put an induction unit under the MLT, but for that you need the right kind of pot and you can't have the nice, neat drain under the vessel like you have.

So I'm not seeing why you have this system set up to be no sparge. It would be quite easy to add a simple picnic cooler and have a sparge setup. Doing so would allow you to run a thinner mash which would filter better and probably extract less tannins from the malt. I'm all for speed and simplicity, but not at the expense of beer quality. But then my thing is lagers, where such imperfections show up and are plain to realize.

Typically a HERMS system is run with a 3rd (heated) vessel. Being that you are planning to use a fully diluted mash, you can probably get away with using the boil kettle as your HERMS heat source, but if you have any hiccups in the brew process its going to be very complicated to recover. I suspect you are planning to circulate the wort in the MLT until its done mashing, then stepping the temp of the mash to the mash out temp (170+) and then quickly draining the BK and pumping the mash over to it. That will work, sort of, but you can't pump it over real fast or you'll get a ton of fines and debris over in the BK. And you'll compact the bed as it drains down and leave a bunch of wort in the mash tun. It has to be pumped over slowly, say 15 minutes or so. And when you do that, I think the temp in the MLT is going to drop quite a bit. Having said all that, I've always been a sparger, so the only thing I know about no sparge is when I run my sparges too fast and these are the problems I run into.

So... if it were me, I'd do the following

- get rid of the MLT filter.

- stick with RIMS, probably turning down the element power by running it on 120V.

- get rid of the BK filter.

- brew 5 batches and see what you learn.

One more thing... I understand wanting to use Triclamp hardware for ease of cleaning, disassembly, etc, but as you found, its expensive, especially when you are making changes during the prototype/testing phase. If I were you I'd make the next round of changes with simple hose and work the bugs out that way. Once you get everything perfected you can plumb it up with TC hardware.

Final comment... you have what I refer to as a boom bust development cycle. You go hard on a design, implement it beautifully, test it once or twice and then its back to the drawing board. I recommend a more incremental approach whereby you plan to go through a couple throw away prototypes as learning experiences and implement things nicely once you have something that works. And spend more time actually using and playing around with and tweaking what you've built before making a big design change.

I love some of the design elements of your system. I'm all for eliminating the 3rd vessel, ie the HLT. I hope you keep working on your system and sharing the results with us.

First off, you aren't having a RIMS problem so much as a circulation problem. Your RIMS setup would probably work fine if you solved the circulation problem, or could be tweaked to be so.

Any grain bed, no matter how its set up is going to flow a ton of fines in the first circulation or whenever its disturbed. Its just a fact of life. No matter what filter you put under the mash vessel is going to get plugged, if its acting as a filter at all. The best advice I can give here is to probably do without the filter under the MLT and your system will work fine. Just replace it with a piece of pipe. I'm not sure why you feel you need a filter there in the first place. If you recirculate the wort for any length of time the bed will begin to act as a filter and it will run crystal clear sooner or later.

Ditto with hops filters off the boil kettle. I'm all for keeping hops out of the fermenter, but that hops filter doesn't have enough area to filter everything coming out of the brew kettle. None of them do. They are designed to catch the odd leftover hop, that sort of thing, not run recirculating wort through, especially non whirpooled recirculating wort.

So my best advice would be to drop both filters and see where that gets you. Run a couple batches like that and see how they come out.

RIMS versus HERMS.

You discovered the drawback of RIMS, that being scorched wort. It isn't a problem if you keep the power low and the flow high, but if you don't watch it closely, you can wreck the batch, as you learned. Even worse than wrecking batches is making batches that have a subtle burnt or dark flavor and not realizing it or not being able to get rid of it.

HERMS has a different problem in that generally the heat exchange to the wort is slow. You'll never scorch the wort, but it takes a long time to do step mashes. This is usually because the delta T of the heating water is low (mash at 150ish, water at 170F if its going to be sparge water), flow rates are low, etc. This is why people direct fire MLTs.

Direct firing an MLT has its place. You can still scorch wort, but its got way more heating area than a RIMS element. Just compare the surface area of the bottom of an MLT with the surface area of a RIMS element. With direct firing you can get a decent amount of heat into the mash and yet not scorch it. The price for this is having a burner under the MLT, something which the eBrew guys want to avoid. An alternative would be to put an induction unit under the MLT, but for that you need the right kind of pot and you can't have the nice, neat drain under the vessel like you have.

So I'm not seeing why you have this system set up to be no sparge. It would be quite easy to add a simple picnic cooler and have a sparge setup. Doing so would allow you to run a thinner mash which would filter better and probably extract less tannins from the malt. I'm all for speed and simplicity, but not at the expense of beer quality. But then my thing is lagers, where such imperfections show up and are plain to realize.

Typically a HERMS system is run with a 3rd (heated) vessel. Being that you are planning to use a fully diluted mash, you can probably get away with using the boil kettle as your HERMS heat source, but if you have any hiccups in the brew process its going to be very complicated to recover. I suspect you are planning to circulate the wort in the MLT until its done mashing, then stepping the temp of the mash to the mash out temp (170+) and then quickly draining the BK and pumping the mash over to it. That will work, sort of, but you can't pump it over real fast or you'll get a ton of fines and debris over in the BK. And you'll compact the bed as it drains down and leave a bunch of wort in the mash tun. It has to be pumped over slowly, say 15 minutes or so. And when you do that, I think the temp in the MLT is going to drop quite a bit. Having said all that, I've always been a sparger, so the only thing I know about no sparge is when I run my sparges too fast and these are the problems I run into.

So... if it were me, I'd do the following

- get rid of the MLT filter.

- stick with RIMS, probably turning down the element power by running it on 120V.

- get rid of the BK filter.

- brew 5 batches and see what you learn.

One more thing... I understand wanting to use Triclamp hardware for ease of cleaning, disassembly, etc, but as you found, its expensive, especially when you are making changes during the prototype/testing phase. If I were you I'd make the next round of changes with simple hose and work the bugs out that way. Once you get everything perfected you can plumb it up with TC hardware.

Final comment... you have what I refer to as a boom bust development cycle. You go hard on a design, implement it beautifully, test it once or twice and then its back to the drawing board. I recommend a more incremental approach whereby you plan to go through a couple throw away prototypes as learning experiences and implement things nicely once you have something that works. And spend more time actually using and playing around with and tweaking what you've built before making a big design change.

I love some of the design elements of your system. I'm all for eliminating the 3rd vessel, ie the HLT. I hope you keep working on your system and sharing the results with us.

Brewman!

Thank you for your detailed response and advice. In fact I have already eliminated both filters, however I did not replace them with new pipes, I simply just cut the screens out of each one where they are "tack" welded and then polished the area smooth as this was cheaper than buying two new 12" pipes. I also have decided to use a brew bag (not as a strainer) but as an easy way to remove the spent grains after mashing. I agree with you 100% that it was a circulation problem and not a RIMS problem, however my thought process is that if one system has the potential to scorch (RIMS) at any giving momement and the other type of system has a 100% No Scorch potential (HERMS) then why would I want to include an element of risk into the brew process that I am fully aware of now that can be eleiminated.

That being said, I have definately eliminated the RIMS system from my rig and have stuck with my plan to use a copper counter flow chiller as a heat exchanger to maintain mash temperatures. I ordered the Large Zchiller from Packless Industries just the other day and plan to use that as the heat exchanger. You mention that the heat exchange in a HERMS is generally slow and used in the traditional way (submerged) in a large volume of water that needs to be heated, I agree with you, but if a counterflow chiller can lower the temperature of wort very rapidly, then it stands to reason that the counterflow chiller can also raise the temperature very rapidly which is the way I plan to use it. I will only need a very small amount of water to heat and recirculate through the coil (maybe 2.5 gallons) so with a 5500 watt elemnet this water should reach temp quite fast and of course I agree with you again in that it will take several test runs to prove my design on paper will actually work.

I thank you for your input and welcome all suggestions from anyone. I plan to brew again in April when my gargae warms up a little. I will post pictures and brew data from this next brew for all to see. Thanks again. Cheers!

Thank you for your detailed response and advice. In fact I have already eliminated both filters, however I did not replace them with new pipes, I simply just cut the screens out of each one where they are "tack" welded and then polished the area smooth as this was cheaper than buying two new 12" pipes. I also have decided to use a brew bag (not as a strainer) but as an easy way to remove the spent grains after mashing. I agree with you 100% that it was a circulation problem and not a RIMS problem, however my thought process is that if one system has the potential to scorch (RIMS) at any giving momement and the other type of system has a 100% No Scorch potential (HERMS) then why would I want to include an element of risk into the brew process that I am fully aware of now that can be eleiminated.

That being said, I have definately eliminated the RIMS system from my rig and have stuck with my plan to use a copper counter flow chiller as a heat exchanger to maintain mash temperatures. I ordered the Large Zchiller from Packless Industries just the other day and plan to use that as the heat exchanger. You mention that the heat exchange in a HERMS is generally slow and used in the traditional way (submerged) in a large volume of water that needs to be heated, I agree with you, but if a counterflow chiller can lower the temperature of wort very rapidly, then it stands to reason that the counterflow chiller can also raise the temperature very rapidly which is the way I plan to use it. I will only need a very small amount of water to heat and recirculate through the coil (maybe 2.5 gallons) so with a 5500 watt elemnet this water should reach temp quite fast and of course I agree with you again in that it will take several test runs to prove my design on paper will actually work.

I thank you for your input and welcome all suggestions from anyone. I plan to brew again in April when my gargae warms up a little. I will post pictures and brew data from this next brew for all to see. Thanks again. Cheers!

The difference between using a counterflow heat exchanger to chill boiling wort and using one to do step mash heating is the delta T of the water to mash.

When you chill wort, the incoming wort is 212F the incoming water is 60F and the outgoing wort is 75 ish F. The flow of incoming water is basically unlimited. Most guys are flowing 3 to 5 GPM of coolant water to 0.5 to 1 GPM of wort.

When you step heat wort, you might be going from 148 to 156 or from 152 to 170F for "sparge" out. Small temp change, seems pretty easy, right ? But the water in the "HLT" is probably only 170 or 190F, so delta T is small, typically less than 20F. Heating the "HLT" water to 210F really helps, but remember that as soon as you pump some water from your "HLT" through the heat exchanger, it gets dumped back into the "HLT" and makes the HLT water cooler. Plus no heat exchanger gets the heated liquid fully up to (or down to ) the temp of the other liquid, in this case the water.

If you have the same volume and mass of liquid in the "HLT" as you have in the "MLT", then theoretically 1F rise in the MLT will happen for every 1F fall in the "HLT". So theoretically 5 gallons of 190F water will heat 5 gallons of wort from 152 to 170F.

In practice its much harder than that because there will be about a 5 to 10F temp difference across the heat exchanger, no matter what and as the temp in the HLT falls, the amount of heat transferred across the heat exchanger falls dramatically.

What I've found is that a HERM system is quite good for keeping a mash warm, but not great for quick temp changes and especially not great for sparge out. By not great, I mean slow.

Your brew stand has a plate chiller on it. You can test all this using water in the MLT quite easily by doing a bit of simple plumbing.

FWIW, I love the idea of brewing indoors using electricity and I dislike the limitations of both RIMS and HERMS. I'm presently trying to assemble a system that uses electrically steam to heat all the brewing vessels.

When you chill wort, the incoming wort is 212F the incoming water is 60F and the outgoing wort is 75 ish F. The flow of incoming water is basically unlimited. Most guys are flowing 3 to 5 GPM of coolant water to 0.5 to 1 GPM of wort.

When you step heat wort, you might be going from 148 to 156 or from 152 to 170F for "sparge" out. Small temp change, seems pretty easy, right ? But the water in the "HLT" is probably only 170 or 190F, so delta T is small, typically less than 20F. Heating the "HLT" water to 210F really helps, but remember that as soon as you pump some water from your "HLT" through the heat exchanger, it gets dumped back into the "HLT" and makes the HLT water cooler. Plus no heat exchanger gets the heated liquid fully up to (or down to ) the temp of the other liquid, in this case the water.

If you have the same volume and mass of liquid in the "HLT" as you have in the "MLT", then theoretically 1F rise in the MLT will happen for every 1F fall in the "HLT". So theoretically 5 gallons of 190F water will heat 5 gallons of wort from 152 to 170F.

In practice its much harder than that because there will be about a 5 to 10F temp difference across the heat exchanger, no matter what and as the temp in the HLT falls, the amount of heat transferred across the heat exchanger falls dramatically.

What I've found is that a HERM system is quite good for keeping a mash warm, but not great for quick temp changes and especially not great for sparge out. By not great, I mean slow.

Your brew stand has a plate chiller on it. You can test all this using water in the MLT quite easily by doing a bit of simple plumbing.

FWIW, I love the idea of brewing indoors using electricity and I dislike the limitations of both RIMS and HERMS. I'm presently trying to assemble a system that uses electrically steam to heat all the brewing vessels.

Brewman!

Thanks again for the follow-up. So are you saying my plan to use a counterflow for holding mash temps won't work at all or are you saying that it will work, but may not be very efficient? I am seriously considering enclosing my copper coil in a custom built box and spraying it full and completely around the counterflow coil with low expansion spray foam insulation to minimize heat loss. Any thoughts? Thanks

Thanks again for the follow-up. So are you saying my plan to use a counterflow for holding mash temps won't work at all or are you saying that it will work, but may not be very efficient? I am seriously considering enclosing my copper coil in a custom built box and spraying it full and completely around the counterflow coil with low expansion spray foam insulation to minimize heat loss. Any thoughts? Thanks

It will work, its just not going to be very fast.

Look at it this way. Once the temp on the HLT water drops a bit the HLT heating element is going to kick in. At that point what you basically have is the HLT heating element heating the MLT contents via heating up the HLT water and running it through the CFHX. That is way, way slower and has way more heat losses and inefficiencies than if that element was operating directly on the MLT liquid as it would be in a RIMS. Probably 50% is lost between the heat lost from the HLT kettle, heat losses in the circulation loop, heat not conducted across the heat exchanger, etc. And if the HLT water temp falls at all, the HX rate really declines.

And the other thing is that you are heating way more thermal mass. Instead of the 5 Kw heating element having to heat the MLT, its now heating all the water in the HLT as well as the MLT.

One other issue with HERMs is temp overshoot. Lets say you want to do a step. So you heat up the HLT water like crazy and do the step. To be effective, the HLT water is going to need to be 30-40F hotter than the MLT water. Now the step is done. You'll probably want to continue recirculating, right ? If you do, your mash is going to continue picking up heat from the HLT water, at least until it comes down a bit. If the MLT and HLT have the same mass, the two temps will meet in the middle, over time. If the HLT water is 40F hotter than the MLT, the MLT mash will overshoot by 20F !

Lets do some calcs. You have a 5 Kw element. Lets say that overall you have 3KW of effective heating after all the losses. Lets say the HLT has 5 gallons (40 pounds) of water in it. Lets say the MLT has 6 gallons (50 pounds) of mash in it.

1 BTU = 1 lb F per hour

1 KWHr = 3412 BTU

3 KW = 10,236 BTU per hour.

We are heating 40 + 50 = 90 pounds of water.

10,236 BTU/90 pounds = 113 F per hour. I'd say this number over states the effectiveness, especially since it assumes that there is always a big enough delta T across the HX that it is effective.

I might be totally out to lunch. I highly suggest you test it with your plate chiller. Get some hose and plumb the MLT flow to go through the garden hose side of the plate chiller. Put 5 gallons of water in the MLT. Put 5 gallons of water in the HLT and heat it. Start circulating the MLT water and plot its temp over time. I'd love to see what you find.

My HERMS system used a direct fired HLT with a big immersion coil that I pumped the mash through and another pump circulating the HLT water. It worked, but it was slow. I was brewing lagers with 2 or 3 mash steps plus mash out and I spent a good part of my day waiting for the temp changes in my mash to occur. And my system had more heating power and less inefficiencies in that yours will. I was using an immersion coil instead of a CFHX. But at low delta Ts an immersion coil doesn't make as much of a difference compared to a CFHX as it does at high delta Ts, like it does when cooling wort.

These posts have been a good exercise for me to remember and realize why I am working on my steam system. My steam system will be running at 30 PSI, providing heat at 275F to any processes that need it. Hot enough to be effective yet no chance of scorching, and its all electric. Hopefully it works in the real world.

Look at it this way. Once the temp on the HLT water drops a bit the HLT heating element is going to kick in. At that point what you basically have is the HLT heating element heating the MLT contents via heating up the HLT water and running it through the CFHX. That is way, way slower and has way more heat losses and inefficiencies than if that element was operating directly on the MLT liquid as it would be in a RIMS. Probably 50% is lost between the heat lost from the HLT kettle, heat losses in the circulation loop, heat not conducted across the heat exchanger, etc. And if the HLT water temp falls at all, the HX rate really declines.

And the other thing is that you are heating way more thermal mass. Instead of the 5 Kw heating element having to heat the MLT, its now heating all the water in the HLT as well as the MLT.

One other issue with HERMs is temp overshoot. Lets say you want to do a step. So you heat up the HLT water like crazy and do the step. To be effective, the HLT water is going to need to be 30-40F hotter than the MLT water. Now the step is done. You'll probably want to continue recirculating, right ? If you do, your mash is going to continue picking up heat from the HLT water, at least until it comes down a bit. If the MLT and HLT have the same mass, the two temps will meet in the middle, over time. If the HLT water is 40F hotter than the MLT, the MLT mash will overshoot by 20F !

Lets do some calcs. You have a 5 Kw element. Lets say that overall you have 3KW of effective heating after all the losses. Lets say the HLT has 5 gallons (40 pounds) of water in it. Lets say the MLT has 6 gallons (50 pounds) of mash in it.

1 BTU = 1 lb F per hour

1 KWHr = 3412 BTU

3 KW = 10,236 BTU per hour.

We are heating 40 + 50 = 90 pounds of water.

10,236 BTU/90 pounds = 113 F per hour. I'd say this number over states the effectiveness, especially since it assumes that there is always a big enough delta T across the HX that it is effective.

I might be totally out to lunch. I highly suggest you test it with your plate chiller. Get some hose and plumb the MLT flow to go through the garden hose side of the plate chiller. Put 5 gallons of water in the MLT. Put 5 gallons of water in the HLT and heat it. Start circulating the MLT water and plot its temp over time. I'd love to see what you find.

My HERMS system used a direct fired HLT with a big immersion coil that I pumped the mash through and another pump circulating the HLT water. It worked, but it was slow. I was brewing lagers with 2 or 3 mash steps plus mash out and I spent a good part of my day waiting for the temp changes in my mash to occur. And my system had more heating power and less inefficiencies in that yours will. I was using an immersion coil instead of a CFHX. But at low delta Ts an immersion coil doesn't make as much of a difference compared to a CFHX as it does at high delta Ts, like it does when cooling wort.

These posts have been a good exercise for me to remember and realize why I am working on my steam system. My steam system will be running at 30 PSI, providing heat at 275F to any processes that need it. Hot enough to be effective yet no chance of scorching, and its all electric. Hopefully it works in the real world.

I don't know what to say about insulating the CFHX. I wouldn't bother right now. Before I did anything, I'd test your system with the plate chiller and see how you like it.

I don't understand why those things use copper outer tubes. They look pretty, but as you realized there is a lot of heat loss. That is not a bad thing if you are using it for cooling and room temp is cooler than the end temp. But its another heat loss when you are using it to heat up a liquid.

I don't understand why those things use copper outer tubes. They look pretty, but as you realized there is a lot of heat loss. That is not a bad thing if you are using it for cooling and room temp is cooler than the end temp. But its another heat loss when you are using it to heat up a liquid.

Brewman!

Thanks for all of your valuable input. I will definately be running some test and posting my results with pics, but since I already purchased the CFHX I will just plan to install it and do the testing with the actual equipment I plan to use. I look forward to seeing how your Electric/Steam system turns out. I have seen many industrial cook kettles in the food industry that use steam for heat and would be awsome for home brew, but still required gas fired boilers to make the steam. Your idea for electric steam is pretty cool. Please let us know how your system turns out. Thanks again.

Thanks for all of your valuable input. I will definately be running some test and posting my results with pics, but since I already purchased the CFHX I will just plan to install it and do the testing with the actual equipment I plan to use. I look forward to seeing how your Electric/Steam system turns out. I have seen many industrial cook kettles in the food industry that use steam for heat and would be awsome for home brew, but still required gas fired boilers to make the steam. Your idea for electric steam is pretty cool. Please let us know how your system turns out. Thanks again.

I have done quite a few no sparge batches on my three vessel HERMS system. They have been always some of my best beers. Keep up the good work. I think you are on to something.

I have done quite a few no sparge batches on my three vessel HERMS system. They have been always some of my best beers. Keep up the good work. I think you are on to something.

Thank you. That is encouraging to hear from someone who has already had sucess with a no sparge HERMS. My CFHX has been delayed shipping due to the bad weather in Texas. Hopefully I will have it by Friday

Finally! - Ok guys. I finally finished making the changes from RIMS to what I call "External HERMS". I brewed another batch of Blonde Ale last weekend and this time the process was flawless. Here are the numbers so far:

8.50 Gallons of 55 degree strike water to 158 degrees in 35 minutes

152 degree mash temp to 168 degree mash out temp in 10 minutes rise time

transfer time from mash tun to boil kettle = 30 minutes

pre-boil volume = 7.75 gallons (target reached)

pre-boil gravity = 1.044 (target 1.042)

post-boil volume = 6.50 gallons (target reached)

post-boil gravity = 1.053 (target 1.052)

Potential ABV = 5.50 % (target was 5% to 5.25%)

efficiency = about 71% (target 70%) Using BIAB method

Original recipe was for 10 pounds of base malt and I used 12 pounds (2 pounds) more added for using the BIAB method

Still in primary fermentation right now, but it is definately not scorched! this time around. I will attempt to attach a couple of pictures of my final design. Cheers!

8.50 Gallons of 55 degree strike water to 158 degrees in 35 minutes

152 degree mash temp to 168 degree mash out temp in 10 minutes rise time

transfer time from mash tun to boil kettle = 30 minutes

pre-boil volume = 7.75 gallons (target reached)

pre-boil gravity = 1.044 (target 1.042)

post-boil volume = 6.50 gallons (target reached)

post-boil gravity = 1.053 (target 1.052)

Potential ABV = 5.50 % (target was 5% to 5.25%)

efficiency = about 71% (target 70%) Using BIAB method

Original recipe was for 10 pounds of base malt and I used 12 pounds (2 pounds) more added for using the BIAB method

Still in primary fermentation right now, but it is definately not scorched! this time around. I will attempt to attach a couple of pictures of my final design. Cheers!

Similar threads

- Replies

- 0

- Views

- 551

- Replies

- 4

- Views

- 633

- Replies

- 9

- Views

- 3K

- Replies

- 4

- Views

- 923