Hello friends. I am at a homebrew impass and need some help. I brew many styles of beer but I have gotten stuck at NEIPA. I’m stuck because I just can’t get it right. My NEIPAs always come out with very muted hop flavor and aroma despite large dry hop additions. They also have a bitterness that is very pronounced initially, then fades somewhat over time. It’s not a nice bitterness.

I’m pretty sure that the culprit for the muted hops is oxygen but I don’t see how. I’ll share my process and maybe folks can offer me some suggestions. I’d be massively appreciative.

-I ferment in a Fermzilla all rounder.

-Sometimes I use a vapor lock, and sometimes I pressure ferment.

-I ferment at room temp usually using Lallemand’s Verdant yeast or Voss Kveik.

- I use a magnet to drop dry hops into the fermenter so o I don’t have to open it.

-I typically don’t cold crash. However, in winter, I sometimes move the fermenter into the cold garage and put 2-5 psi on it to prevent the sides from collapsing as it cools.

- For transfer I start by filling a keg with sanitizer and then pushing it out with CO2. So theoretically there’s only CO2 in the keg. Then I pressure transfer the fermented beer to the keg, letting the CO2 out with a spunding valve.

- Carbonation: I burst carb at 50 psi for 18 hrs.

I use the NEIPA recipe that Treehouse put out via their YouTube channel. It calls for 10.2 oz of dry hop divided equally between Amarillo, Citra, and Simco.

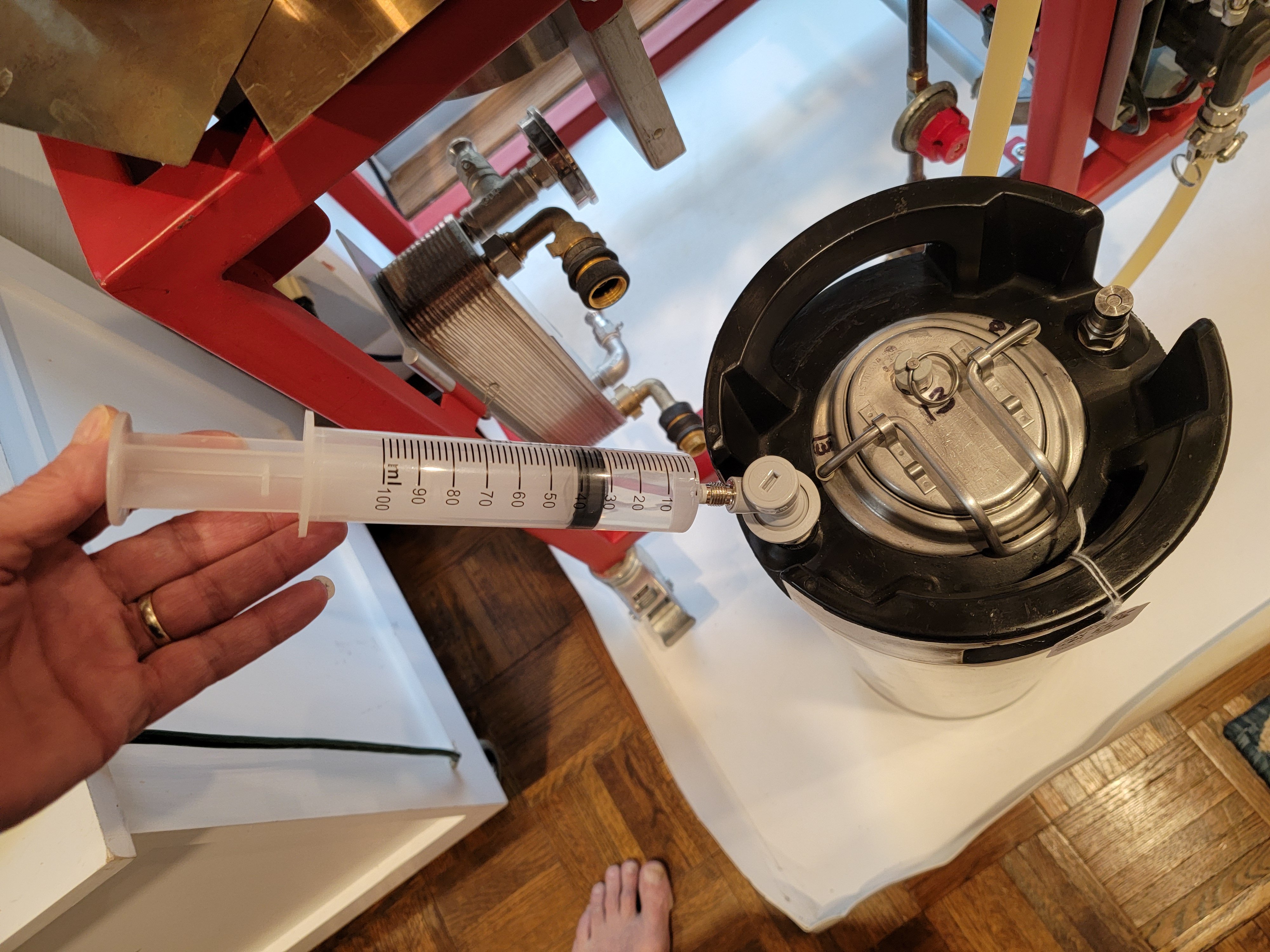

That’s it. I’m running out of things to try in terms of keeping oxygen out. Perhaps adding SMB when I transfer to the keg? I have shied away from this because I’d have to open the purged keg to add it.

Thanks for sticking with this long post. And thanks for any consideration anyone might give.

Cheers,

Adam

I’m pretty sure that the culprit for the muted hops is oxygen but I don’t see how. I’ll share my process and maybe folks can offer me some suggestions. I’d be massively appreciative.

-I ferment in a Fermzilla all rounder.

-Sometimes I use a vapor lock, and sometimes I pressure ferment.

-I ferment at room temp usually using Lallemand’s Verdant yeast or Voss Kveik.

- I use a magnet to drop dry hops into the fermenter so o I don’t have to open it.

-I typically don’t cold crash. However, in winter, I sometimes move the fermenter into the cold garage and put 2-5 psi on it to prevent the sides from collapsing as it cools.

- For transfer I start by filling a keg with sanitizer and then pushing it out with CO2. So theoretically there’s only CO2 in the keg. Then I pressure transfer the fermented beer to the keg, letting the CO2 out with a spunding valve.

- Carbonation: I burst carb at 50 psi for 18 hrs.

I use the NEIPA recipe that Treehouse put out via their YouTube channel. It calls for 10.2 oz of dry hop divided equally between Amarillo, Citra, and Simco.

That’s it. I’m running out of things to try in terms of keeping oxygen out. Perhaps adding SMB when I transfer to the keg? I have shied away from this because I’d have to open the purged keg to add it.

Thanks for sticking with this long post. And thanks for any consideration anyone might give.

Cheers,

Adam