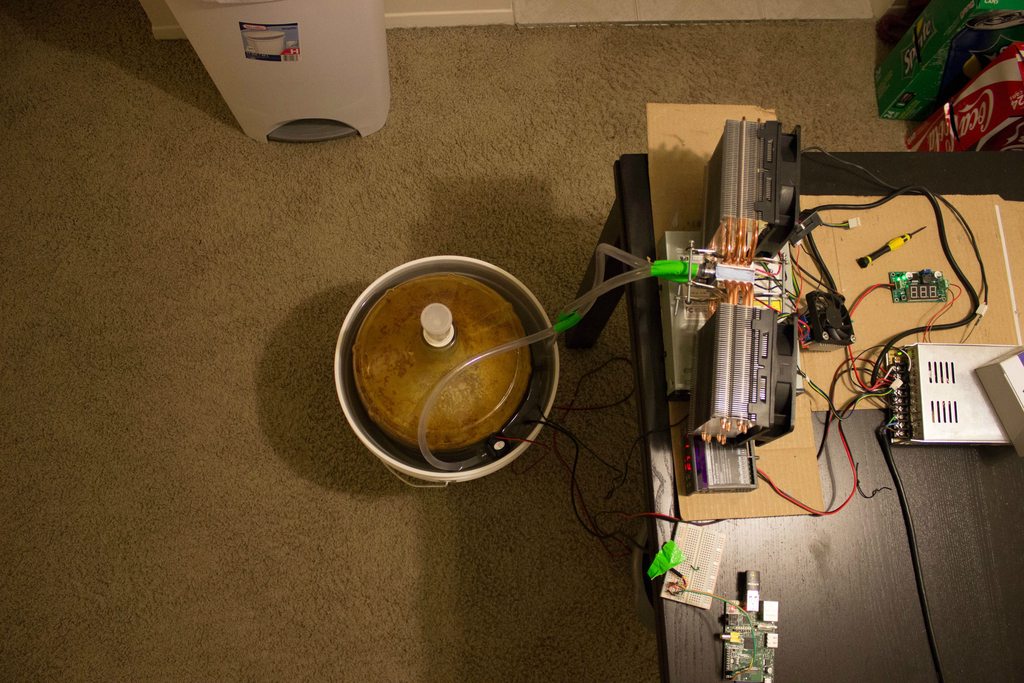

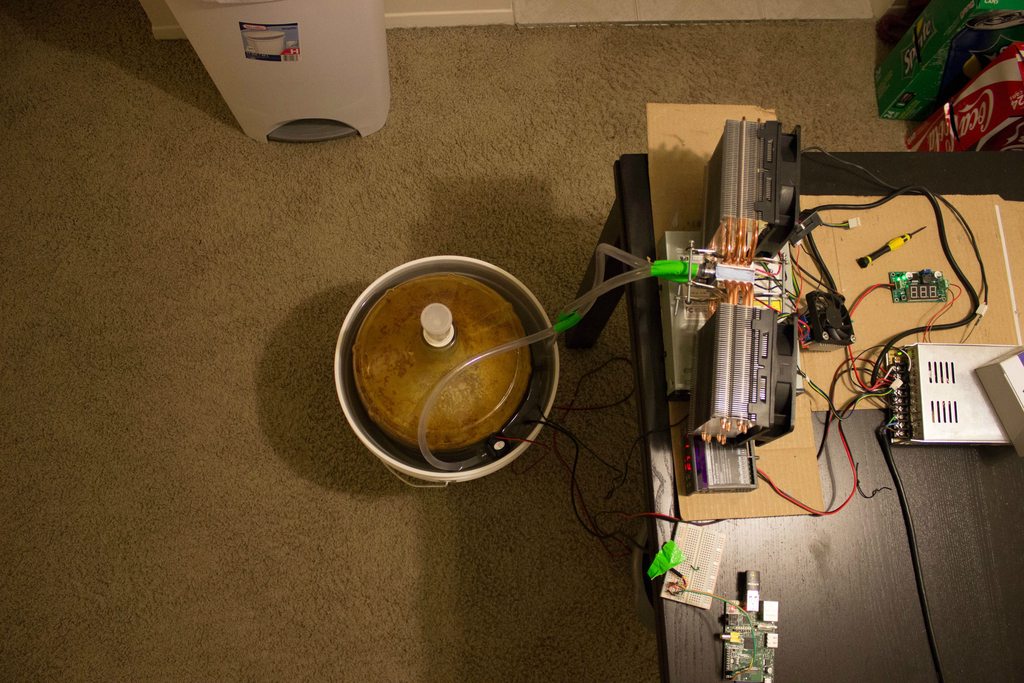

Before I started brewing my first beer, I wanted to setup a way to cool my carboy down to a desired temperature. I looked into purchasing a refrigerator but I don't really have room in my apartment for an appliance like that. So instead I built this!

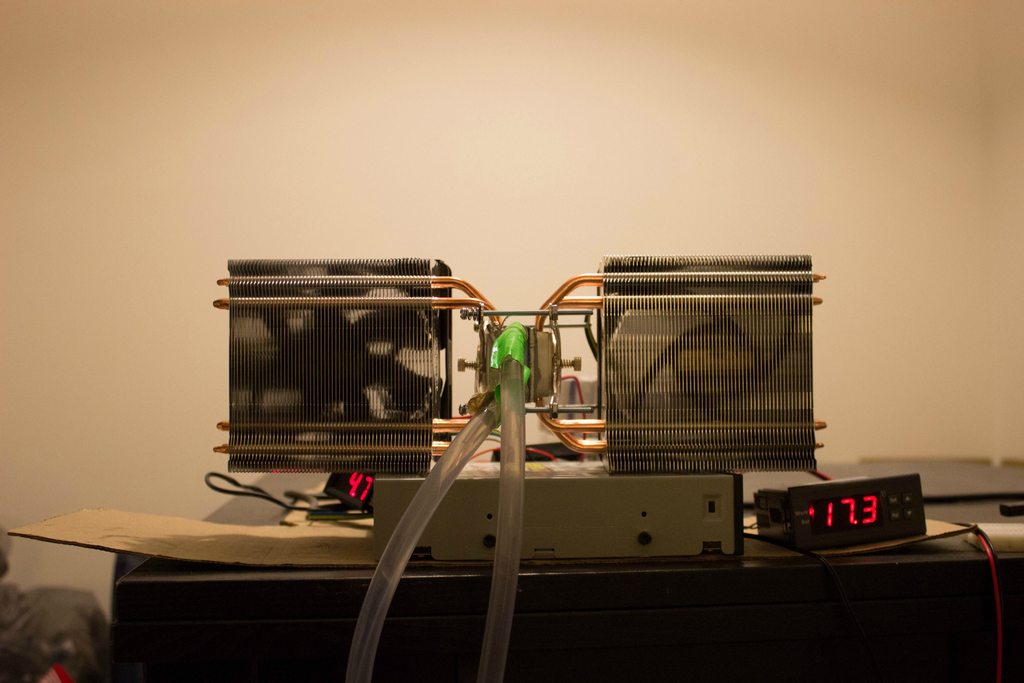

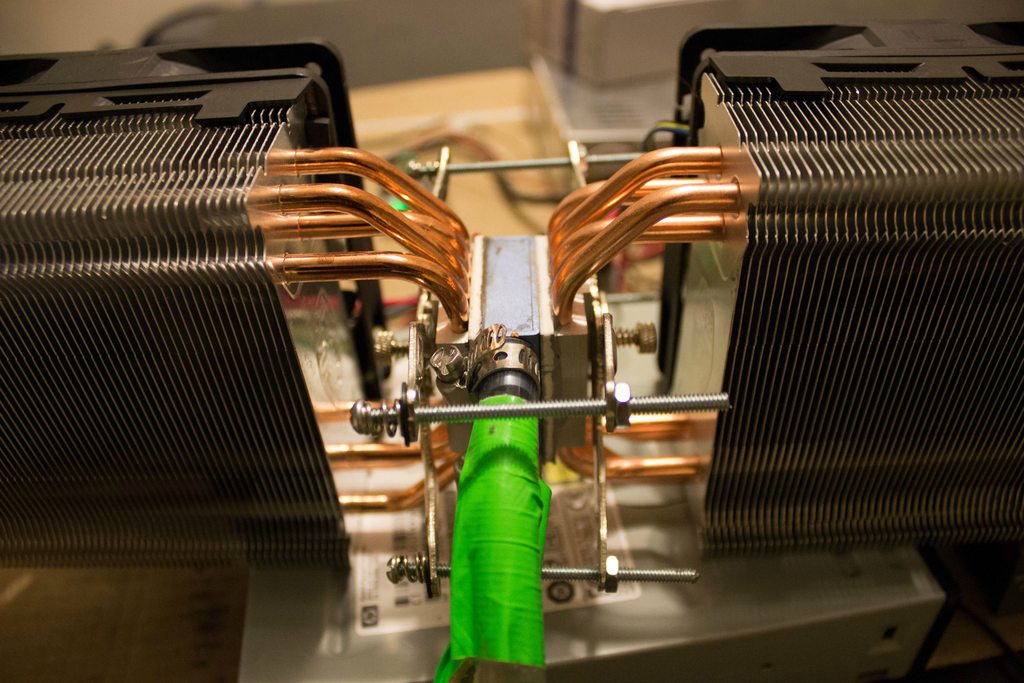

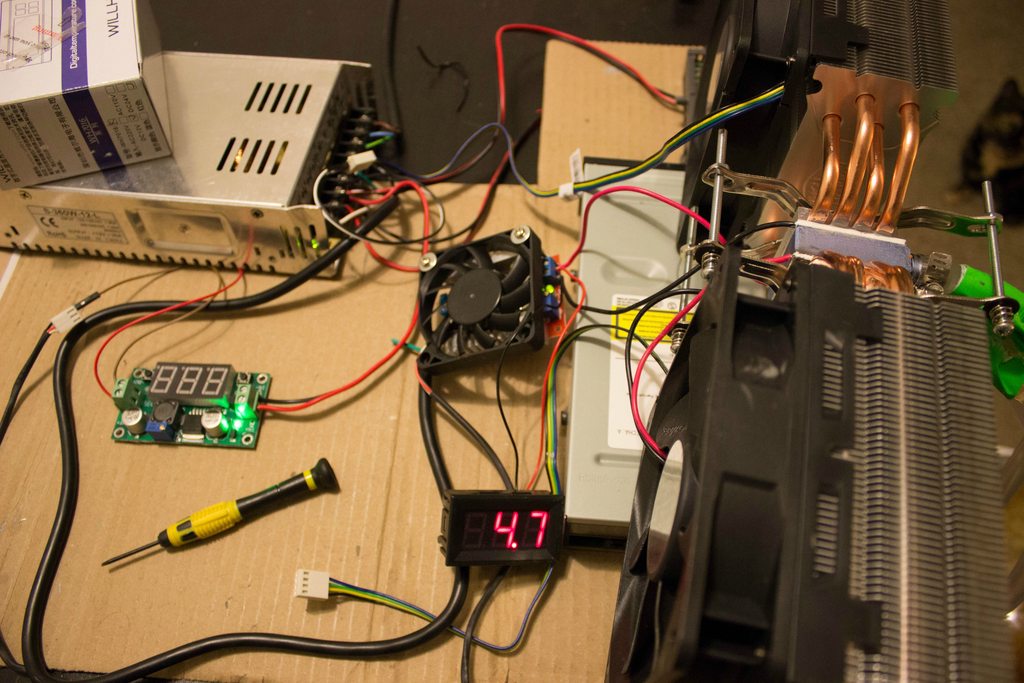

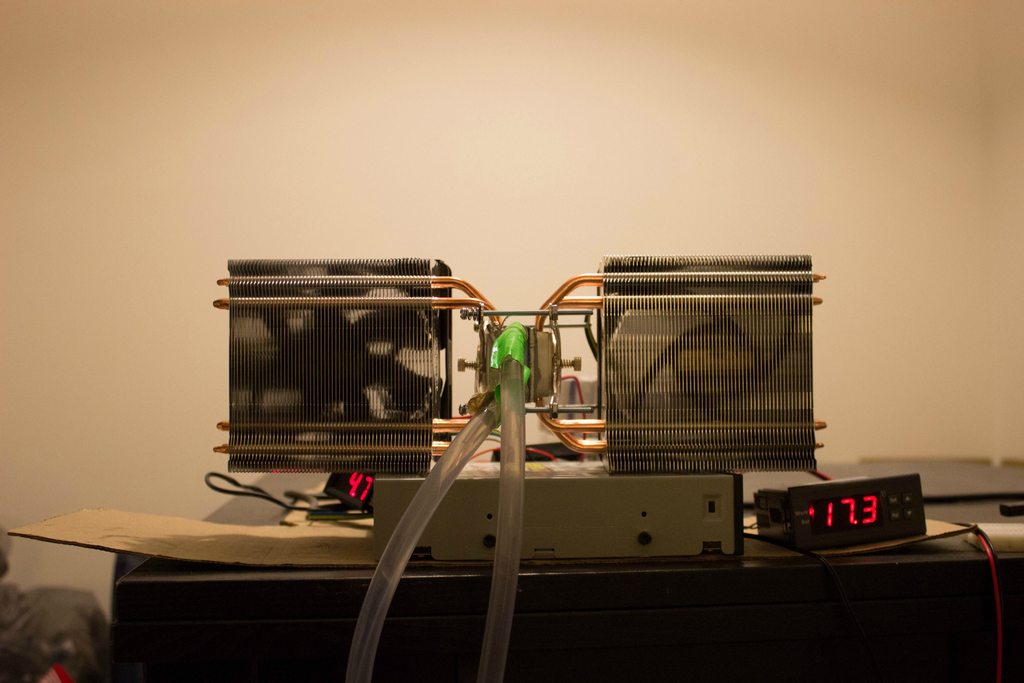

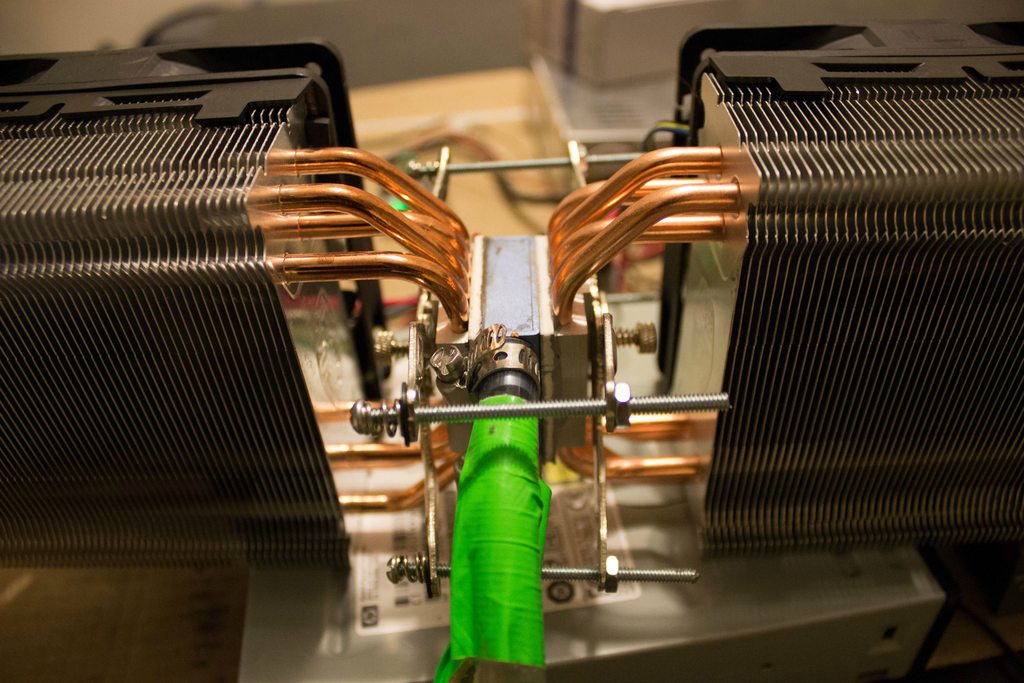

I purchased two used CPU heatsinks off Amazon (http://www.amazon.com/gp/product/B002G1YPH0/?tag=skimlinks_replacement-20) placing my water block (http://www.amazon.com/gp/product/B00DHC2GJ6/?tag=skimlinks_replacement-20) and two peltiers between each side of the water block and the heatsink, thermal paste on each side. I ordered a 12V 30A power supply to run all this. One pelteir is a TEC-12706 which uses 60W @12V. The other is a TEC-12715 which uses 140W @12V; both pelteirs can run @ 15.4V. I also purchased a "buck step down voltage regulator" (http://www.amazon.com/dp/B00C4QVTNU/?tag=skimlinks_replacement-20) to drop the voltage to control temperature.

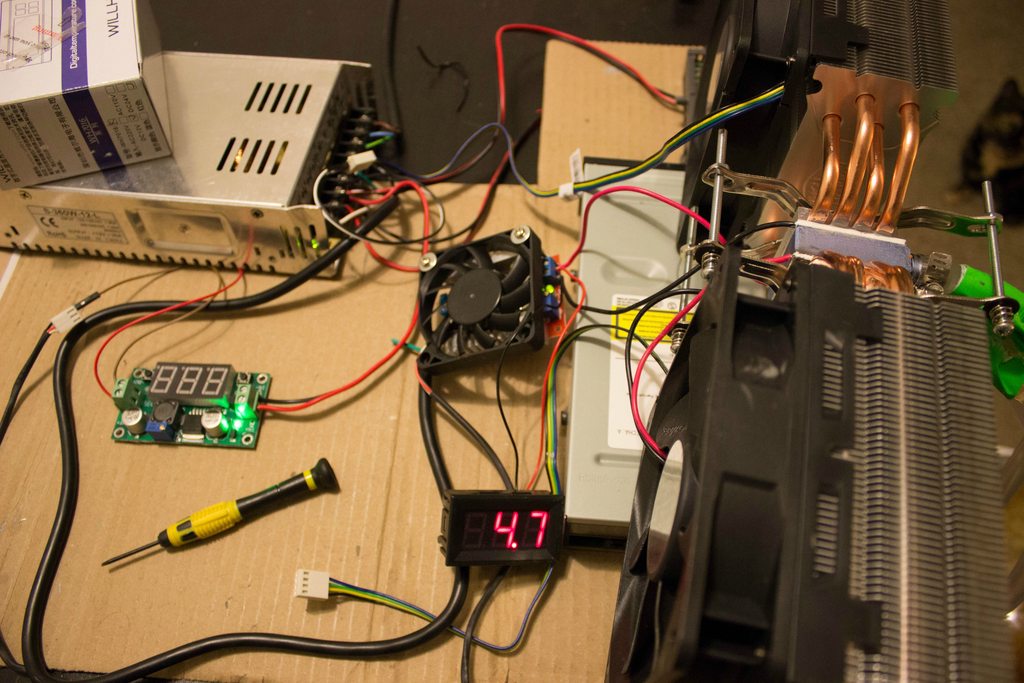

Currently I'm able to maintain the water temperature surrounding the carboy at 62F (75F ambient) with only the more powerful cooler running @ 4.6V through the step down converter. With the two fans running (one in the power supply, the other on the heatsink) I'm drawing 40W according to my Kill-A-Watt. The yeast temperature range was 60-72, so I figured 60-62F water surrounding the carboy would be sufficient.

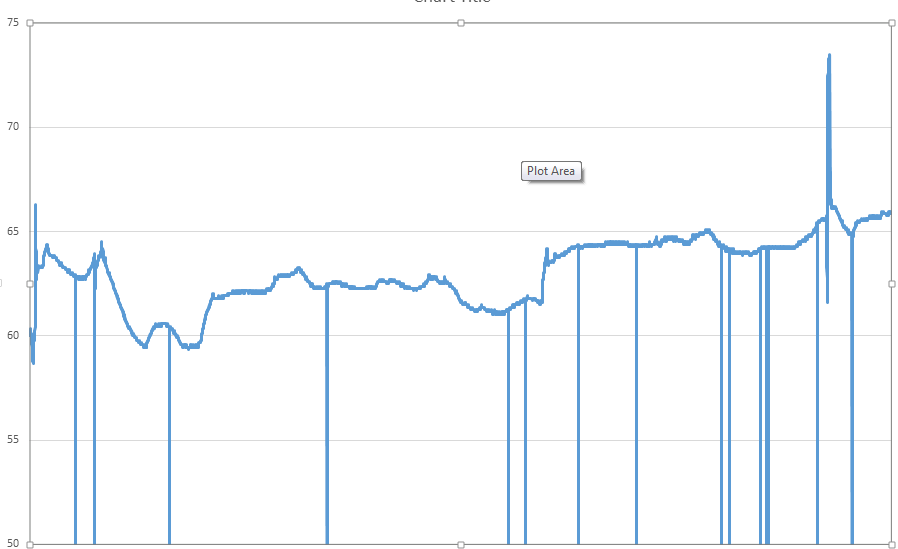

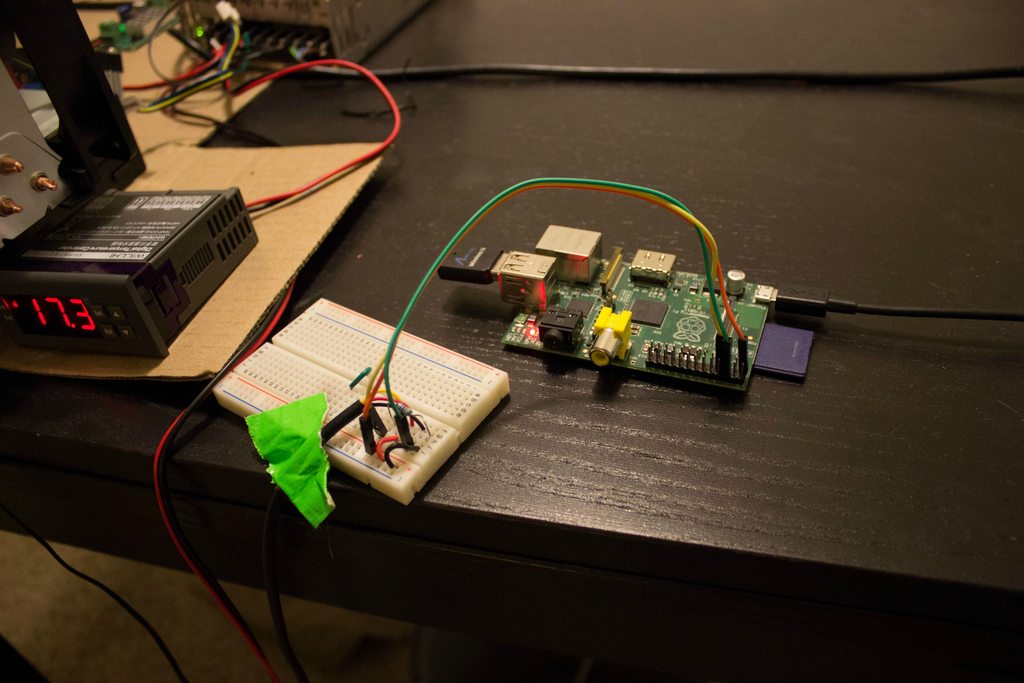

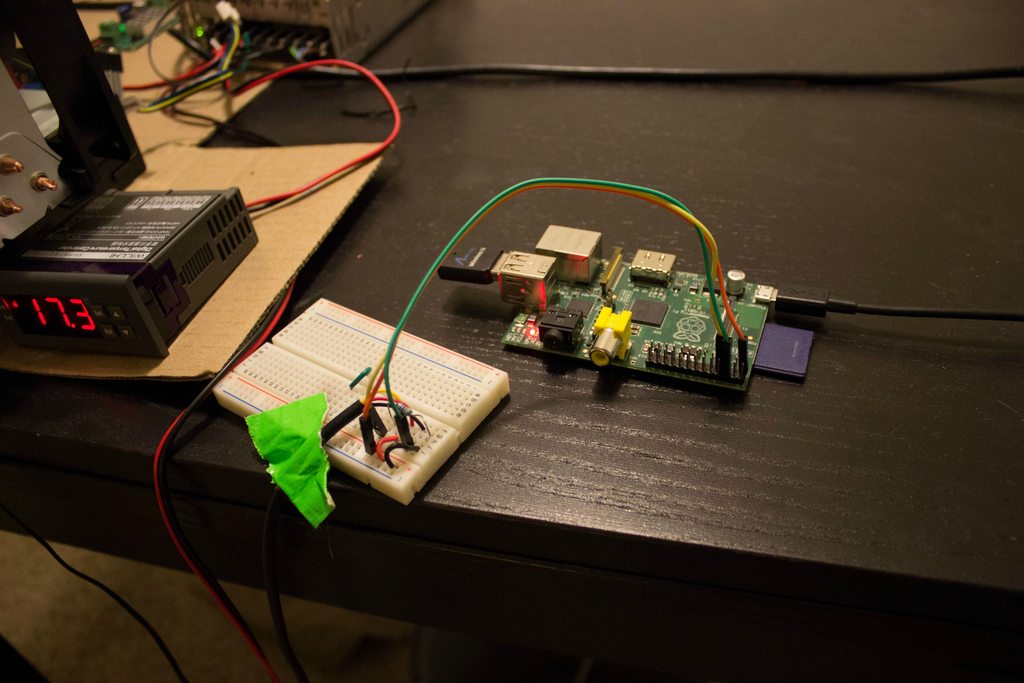

I'm monitoring the temperature via my Raspberry Pi which writes to a file that I can view via http.

After I ordered everything I found this article which helped me (attempt) to make calculations: http://www.shine7.com/aquarium/chiller.htm The digital temperature controller is a POS, it reverses the polarity immediately when the temperature drops out of range and heats the water with the same current!!

The next step might be staging different voltages with a relay board for the Pi so I can maintain temperature in a varying environment.

I purchased two used CPU heatsinks off Amazon (http://www.amazon.com/gp/product/B002G1YPH0/?tag=skimlinks_replacement-20) placing my water block (http://www.amazon.com/gp/product/B00DHC2GJ6/?tag=skimlinks_replacement-20) and two peltiers between each side of the water block and the heatsink, thermal paste on each side. I ordered a 12V 30A power supply to run all this. One pelteir is a TEC-12706 which uses 60W @12V. The other is a TEC-12715 which uses 140W @12V; both pelteirs can run @ 15.4V. I also purchased a "buck step down voltage regulator" (http://www.amazon.com/dp/B00C4QVTNU/?tag=skimlinks_replacement-20) to drop the voltage to control temperature.

Currently I'm able to maintain the water temperature surrounding the carboy at 62F (75F ambient) with only the more powerful cooler running @ 4.6V through the step down converter. With the two fans running (one in the power supply, the other on the heatsink) I'm drawing 40W according to my Kill-A-Watt. The yeast temperature range was 60-72, so I figured 60-62F water surrounding the carboy would be sufficient.

I'm monitoring the temperature via my Raspberry Pi which writes to a file that I can view via http.

After I ordered everything I found this article which helped me (attempt) to make calculations: http://www.shine7.com/aquarium/chiller.htm The digital temperature controller is a POS, it reverses the polarity immediately when the temperature drops out of range and heats the water with the same current!!

The next step might be staging different voltages with a relay board for the Pi so I can maintain temperature in a varying environment.

Last edited by a moderator: