This is going to be long. I'm going to try and prevent that, then fail. Sorry about that.

My old mill died. Ended up saving the last brewday by double crushing - and ending up with massacred malt as a result. But I brewed! Enough is enough. I had taken a break from brewing and forgot how bad things were getting. Hopping back into the swing of things with infuriating equipment. Fantastic. I lost faith in "friction driven" secondary and/or tertiary rollers.

The Australian made Millmaster grain mill. Hardened stainless rollers. Fluted rollers instead of knurled. Gear driven secondary roller. This is some exciting kit. I also can't find it this side of the ocean. $340 CAD or $250 USD including shipping and import taxes. Looking at some of the premium branded 3 roller mills, they're even more expensive. Even a "decked out" 2 roller mill is in the same price range. Let's do this.

That's some quality packing they have there. Mill arrived in perfect shape, just a touch of damage to the cardboard box where the axle poked it a bit. I didn't buy this for the cardboard. The tiny pin on the left is the key. When this gets a permanent motor and gear reducer the keyway is going to transmit power to the mill. Set screws need not apply. As far as mounting screws go none were included. It also would have been nice to get some documentation with it, or even stamp the metal with screw size required. 1/4-20 just in case you were wondering.

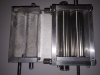

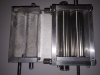

Friction driven rollers begone! You may notice from the first image they've included a guard to prevent your grain from falling into the gears. There's the fluting up close and personal. Always a void between the portion of rollers. The adjustment will allow the closer portions of the roller to get closer than I'd ever like them to.

Once again, I like what I see. Huge easy to grip adjustment knob with many well marked lines. No screwdriver required for gap adjustments. Not that I did so previously. Maybe now I will. Anti-slip shape on the shaft for a drill to grip. Current gap is wide enough for the non-embossed portion of a credit card to fit, but the embossed portion to bind. Seems like a good starting point.

This image does not do it justice. It is probably triple the weight. Heavy=quality right? Mounted it up to the old bucket top plate with some modifications of course, and re-used the old hopper. Needed some custom fabricated brackets, but that's the way it goes when you don't buy the hopper kit. If anyone wants to donate one for review, I'll be happy to. This thing crushed through a full hopper like I never imagined a 12V drill could. 3 KG (6.6LB) in 1:30 - impressive. Set to 350RPM on low speed, it's right in the 110-500 range the manufacturer recommends. With a load I'm assuming that speed dropped a bit.

At first this looked a little coarse to me. I did check it before the whole grist was milled, then decided to rock on with it as it. In acknowledgement of scientific process existing, try to reduce variables. Did a bit of research on how a crush should look, having been out of the game for a while. Still looked coarse. That little guy in the bottom right corner should be paid attention to. Looked untouched from the other side but when turning it around the husk is open and the meat is cracked. Good enough for day 1.

Mashing in I could tell there was a lot less dust than I had gotten used to. Particularly from that double crush salvage day - the day most recent and best remembered. Stirred like a dream. After 75 minutes, it's time to drain. Go with a quick vorlauf and get about 10 pieces of cracked grain. Then as clear wort as a stout grist could give me. This bodes well for a quick non-stuck sparge. That tun drained faster than I'd ever drained before. Almost as though there was no grain bed at all. Perhaps my extract rate suffered. Batch sparge and it drained like a regular 10g cooler would without 8KG (17.6? lbs) of grain in the bottom.

Turns out that the efficiency according to my software was 75% and coming in at OG 1.042. Not sure if that's the pre or post boil efficiency, but the same software would usually give 80-85 on a similar grist bill. Based on how the crush looked a bit coarse, the tun draining in record time, and the slightly lower than expected extract I'll be tightening the gap a little for future brews.

I hope this wasn't too long winded. So far I have no problems with it, and it seems to be the real deal that I hoped it would be. Time will tell. It is strictly the fact that I have only used this once that I feel unqualified to recommend this product. I'll be following up with any problems I encounter or revelations, and certainly after that next batch. Feel free to ask any questions about the mill here.

My old mill died. Ended up saving the last brewday by double crushing - and ending up with massacred malt as a result. But I brewed! Enough is enough. I had taken a break from brewing and forgot how bad things were getting. Hopping back into the swing of things with infuriating equipment. Fantastic. I lost faith in "friction driven" secondary and/or tertiary rollers.

The Australian made Millmaster grain mill. Hardened stainless rollers. Fluted rollers instead of knurled. Gear driven secondary roller. This is some exciting kit. I also can't find it this side of the ocean. $340 CAD or $250 USD including shipping and import taxes. Looking at some of the premium branded 3 roller mills, they're even more expensive. Even a "decked out" 2 roller mill is in the same price range. Let's do this.

That's some quality packing they have there. Mill arrived in perfect shape, just a touch of damage to the cardboard box where the axle poked it a bit. I didn't buy this for the cardboard. The tiny pin on the left is the key. When this gets a permanent motor and gear reducer the keyway is going to transmit power to the mill. Set screws need not apply. As far as mounting screws go none were included. It also would have been nice to get some documentation with it, or even stamp the metal with screw size required. 1/4-20 just in case you were wondering.

Friction driven rollers begone! You may notice from the first image they've included a guard to prevent your grain from falling into the gears. There's the fluting up close and personal. Always a void between the portion of rollers. The adjustment will allow the closer portions of the roller to get closer than I'd ever like them to.

Once again, I like what I see. Huge easy to grip adjustment knob with many well marked lines. No screwdriver required for gap adjustments. Not that I did so previously. Maybe now I will. Anti-slip shape on the shaft for a drill to grip. Current gap is wide enough for the non-embossed portion of a credit card to fit, but the embossed portion to bind. Seems like a good starting point.

This image does not do it justice. It is probably triple the weight. Heavy=quality right? Mounted it up to the old bucket top plate with some modifications of course, and re-used the old hopper. Needed some custom fabricated brackets, but that's the way it goes when you don't buy the hopper kit. If anyone wants to donate one for review, I'll be happy to. This thing crushed through a full hopper like I never imagined a 12V drill could. 3 KG (6.6LB) in 1:30 - impressive. Set to 350RPM on low speed, it's right in the 110-500 range the manufacturer recommends. With a load I'm assuming that speed dropped a bit.

At first this looked a little coarse to me. I did check it before the whole grist was milled, then decided to rock on with it as it. In acknowledgement of scientific process existing, try to reduce variables. Did a bit of research on how a crush should look, having been out of the game for a while. Still looked coarse. That little guy in the bottom right corner should be paid attention to. Looked untouched from the other side but when turning it around the husk is open and the meat is cracked. Good enough for day 1.

Mashing in I could tell there was a lot less dust than I had gotten used to. Particularly from that double crush salvage day - the day most recent and best remembered. Stirred like a dream. After 75 minutes, it's time to drain. Go with a quick vorlauf and get about 10 pieces of cracked grain. Then as clear wort as a stout grist could give me. This bodes well for a quick non-stuck sparge. That tun drained faster than I'd ever drained before. Almost as though there was no grain bed at all. Perhaps my extract rate suffered. Batch sparge and it drained like a regular 10g cooler would without 8KG (17.6? lbs) of grain in the bottom.

Turns out that the efficiency according to my software was 75% and coming in at OG 1.042. Not sure if that's the pre or post boil efficiency, but the same software would usually give 80-85 on a similar grist bill. Based on how the crush looked a bit coarse, the tun draining in record time, and the slightly lower than expected extract I'll be tightening the gap a little for future brews.

I hope this wasn't too long winded. So far I have no problems with it, and it seems to be the real deal that I hoped it would be. Time will tell. It is strictly the fact that I have only used this once that I feel unqualified to recommend this product. I'll be following up with any problems I encounter or revelations, and certainly after that next batch. Feel free to ask any questions about the mill here.