BeerMe82

Well-Known Member

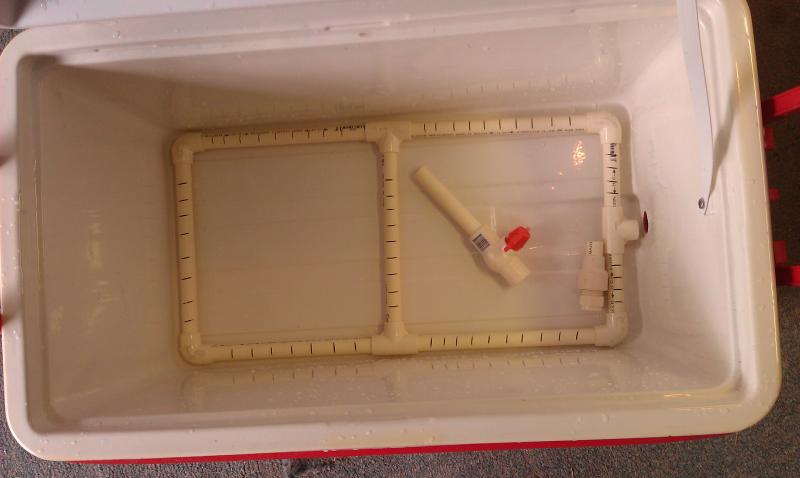

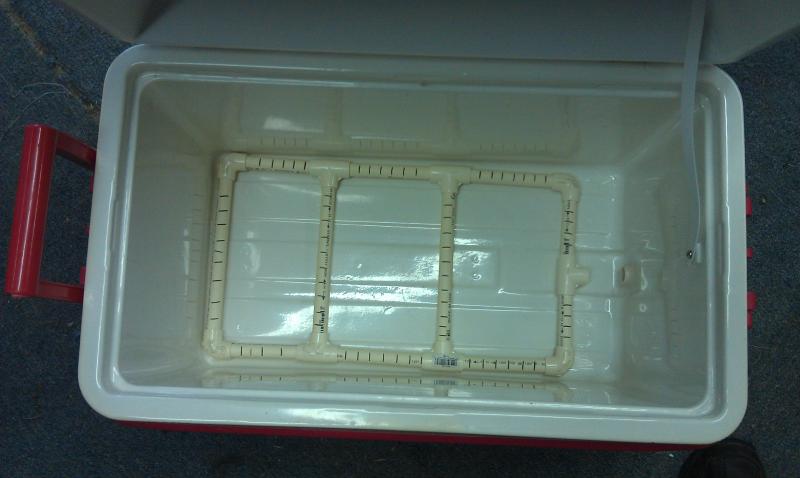

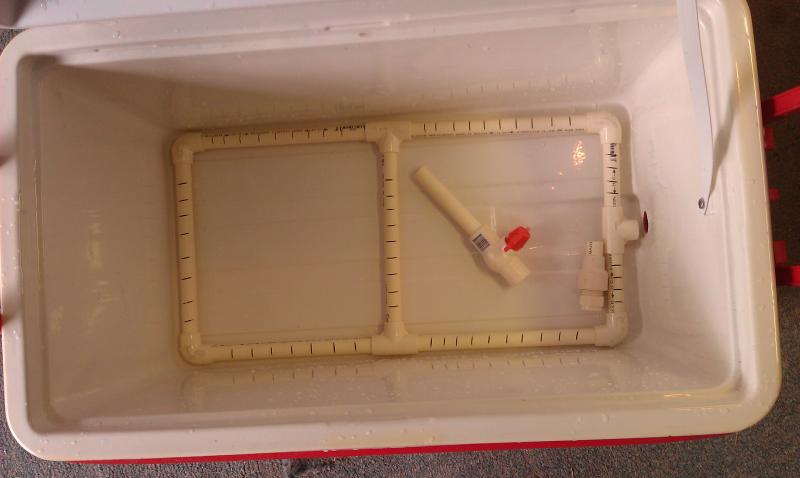

So im in the end stages of constructing my first mash tun. I used all 1/2 cpvc and it will have a brass hose adapter on the out side. I will seal/ glue the pass through with silicone. I hope it will be strong enough, but I think ill be fine. Im wondering if I should shorten the center cross pipes to bring the tubing more toward canter, to get a more even drain off. Any opinions would help. Tnx.

After I get all of this done, Ill probably use the extra cpvc to create something of a fly sparging thing on the lid.

After I get all of this done, Ill probably use the extra cpvc to create something of a fly sparging thing on the lid.