Possibly... No idea how to quantify that. Guessing its not anything to get bent around the axle on though.

Probably not that extreme in significance

But the difference - like 15+ times higher dissipation than some 12 VDC fans of the same size - can translate into significantly more frequent compressor cycling. Even 12 VDC fans can affect cycle time: I run a single 120mm air mover and pair of 40mm fans driving air into my two EVA DRY 500 dessicators, and with them on the keezer will cycle 4 times a day this time of year, while with them off it'll be almost

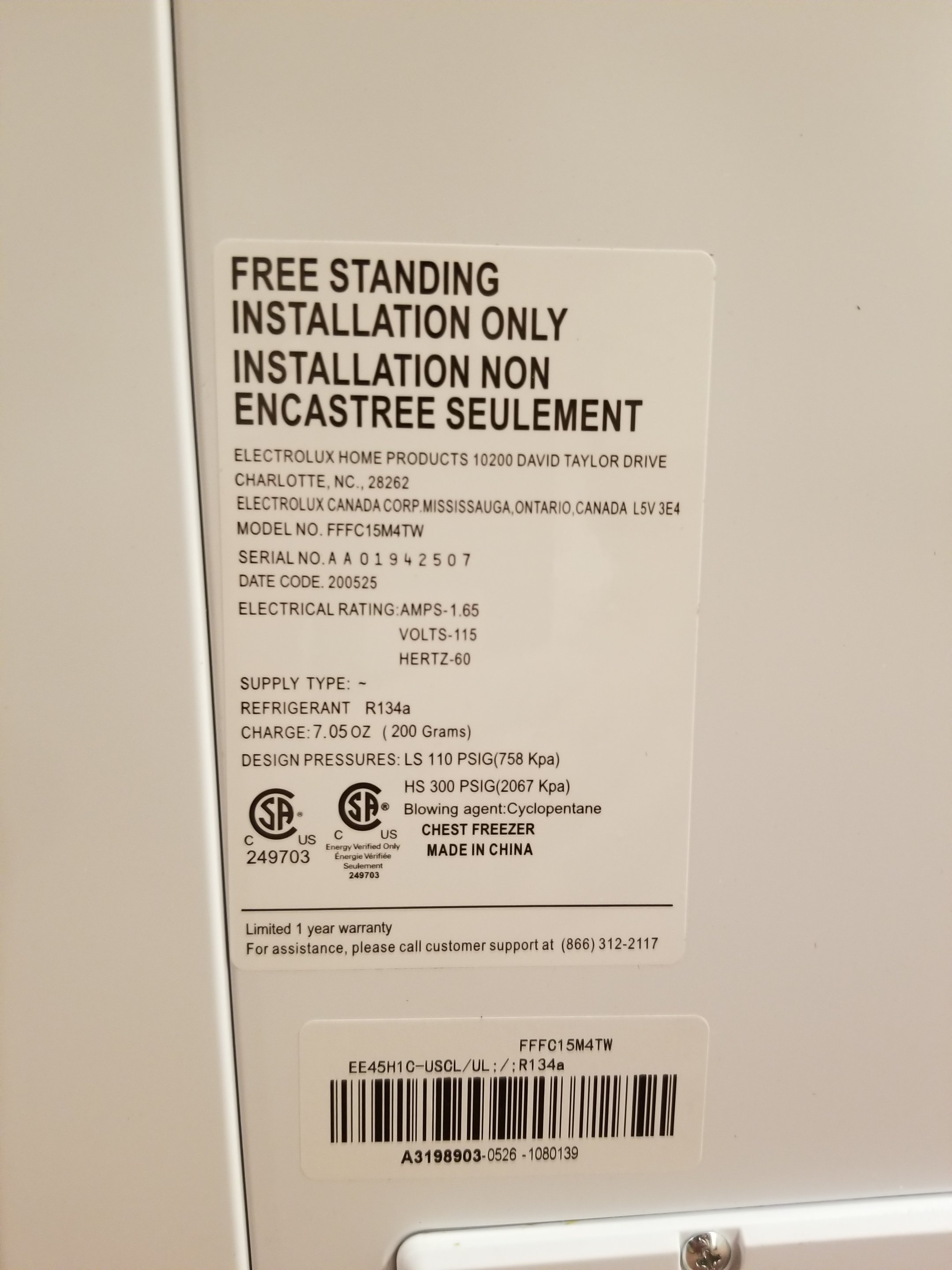

What's the make and model number of your fan?

Cheers!

Last edited: