Beavdowg

Well-Known Member

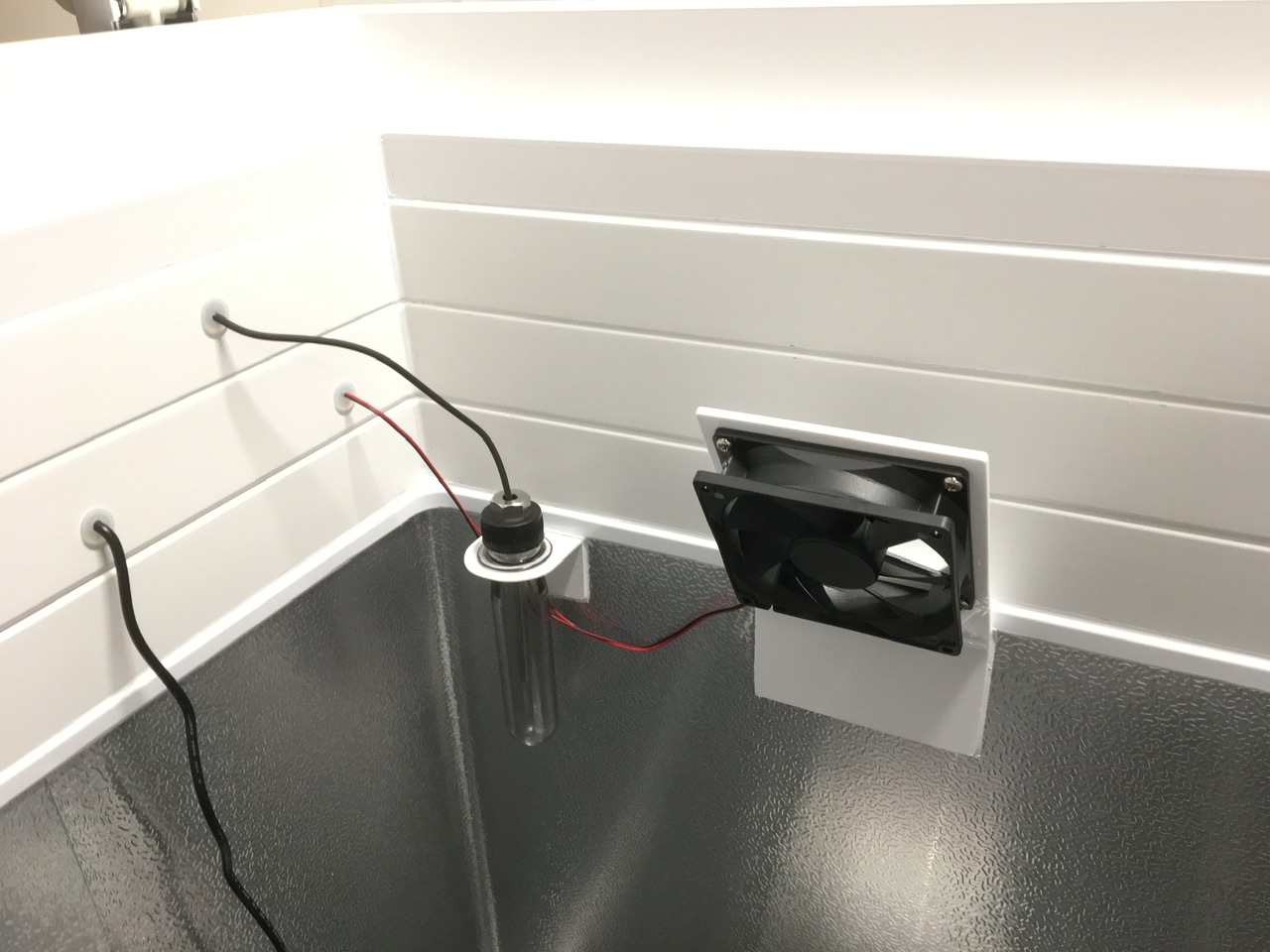

I recently got a chest freezer and am thinking about puttinga CPU fan inside it to help with the cool air circulation. I've read of others doing this. My question is how do you wire the fan into the system? Is the fan always on or does it come on only when the freezer turns on? I am not an electrician whatsoever so if this aint easy it just won't happen. Can you just plug in one of those "2 plugs into 1" into the temp controller so that when the temp controller turns on the freezer it turns on the fan also?

thanks

thanks