I would add "... If you expect precise temp control with zero over/under shoot."

In my (non brewing) experience that's exactly what you go to PID for and that's why I elected to use PID in brewing.

In many cases brewers use PIDs that have never been auto-tuned and don't have wild swings.

'Wild' is, of course, a subjective term. A controller ships with a nominal tune set. If it closely matches the load then performance can be quite good. If it doesn't, then things get wild - no poles in the right half plane or anything like that but overshoot can be substantial and it can take a long time for things to damp out. Simply tuning the system will improve that performance dramatically if the system is one amenable to PID control. I'll get specific in a minute.

I guess it's the definition of the word "reasonable" that has me say that I find that even without auto-tuning, many brewers will find the results reasonable. I know that a large % of brewers using PIDs to maintain mash temp have never done auto-tuning and are happy with the results. (Just based on email feedback).

If they are happy, I am happy.

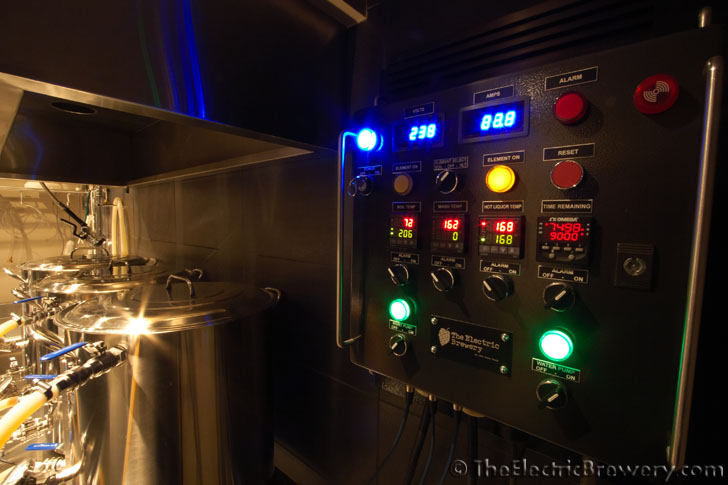

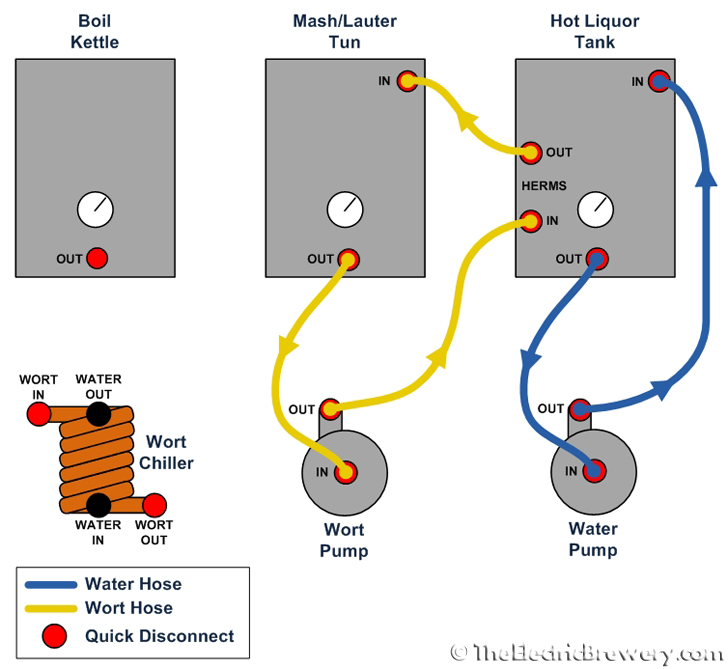

I brew beers with between 10 to 40 lbs of grain depending on what I'm making (a 3.5% light lager to a 12%+ barley wine). I don't re-autotune between batches nor do I have issues holding mash temp correctly. If I set my HLT to be 150F (I have a HERMS setup), the HLT holds at 150F and my mash then also reaches and holds at 150F

I'll have to ask you to forgive my total ignorance of HERMS beyond what I could find from a quick web search. I understand from that that the liquid from the mash tun is recirculated through a heat exchanger in the HLT and that the reading of an RTD usually at the output of the heat exchanger is the PV and that the output of the controller turns on the recirculation pump or the HLT heater. In either case you are asking the system to control the temperature of the output of the HLT. This is an example of not regulating the load but some other point in the system. If PV reads 150 °F, what is the temperature of the mash at the point where the hot wort enters the mash tun? At the point where it leaves? In the middle?

These may not be pertinent questions as in your system the RTD might be located in the middle of the mashtun or the PV might be the average of the readings of RTD's dispersed throughout it.

In any case, if you increase the mass of the grain and water, for example, the thermal time constant of the system will increase and for good PID performance the tune set should be changed. If your response to that is that the size of the load changes you make doesn't degrade performance enough to be of concern I can certainly accept that.

Most of my 3-4% light lagers that only have ~10 lbs of grain are 3+ hours multistep mashes and they hit temps perfectly without any over/undershoot. My 12% beers with 40lb of grain simply take longer to step/reach temp.

I don't get inaccurate mash temps based on the amount of grain/water. Sometimes it's 4 times the amount of grain even!

That says you are way over damped.

I think brewing setups are all fairly heavily dampened and take (relatively speaking) a long time for temps to change such that you don't need to have multiple sets of P/I/D values based on amount of grain/water/etc. I don't know anyone who does this.

So they aren't really PID then but rather over damped first order loops. In a commercial operation where they want to get to temp quickly I expect they would shoot for critical damping or at least an operation that had a knowledgeable engineer in the loop would. It never occurred to me to ask a pro brewer about his tuning. Probably set up by the consultant and never touched again in many cases.

In brewmcq's case something is definitely wrong as you mentioned.

That's probably the case.

The usual problems in home brewing are that the RTDs (temperature sensors) aren't sensing the load and that the load is not uniformly and consistently stirred.

But that's only if the load (mash) is not actually at the temp that the RTD says it thinks it's at.

The location of the temperature sensor at a place other than where the load is located, e.g. the HERMS example I cited above or at the output or input of a RIMS heater chamber are examples of the RTD not controlling the load. Note that this can be workable if the offset between the sense temperature and the load temperature is constant (and known). Another example, and more what I was thinking of, would be my HLT which is a 55 gal SS drum with a steam coil in the bottom. The RTD is located adjacent to the steam coil. If I fire this puppy off it regulates the temperature of the water near the steam coil but that's not the temperature of the load (which is the whole mass of the water). A small recirculating pump fixes the problem and, when tuned for about 30 gal, the controller works very well. Steam stays on until within a few degrees of SP (band is small), only overshoots by a couple of tenths of a degree, settles out quickly, responds quickly to opening the cold water fill valve (D is properly set) and performance doesn't degrade noticeably if the tank is filled to 80% as opposed to 66%. That's what I want PID to do.

Now if we move to the mash tun, built the same way, there is no means that I have found, by which I can mix the mash uniformly enough to actually control the load from the single RTD reading so I turn the steam on and off manually (or pedally, actually,i.e. with a foot pedal). PID becomes PED.

Interesting discussion. I've gained some insights from it.