Carlscan26

Well-Known Member

They have a 50 amp package for $1600 - just barely outside your goal budget...

They have a 50 amp package for $1600 - just barely outside your goal budget...

Hoppopotomus said:Ignorance I guess.I was under the impression that refrigeration units should technically be on their own 20 amp. dedicated circuit, so the power feed for the temp. controler that supplies the lager chamber plugs into a dedicated 20 amp. outlet on it's own circuit. The ale chamber power feed plugs into a 15 amp. outlet.

Anyways.....I finished sanding my kegs and got most of the plumbing put back together last night. Pics. later today, but we are in the middle of having an inground swimming pool installed, so my time is very limited outside of work. Not enough hours in the day!

I have used the mill a half dozen times down there. There is a little dust at the top end of the mill, but not bad at all. The grain drops down a chute into a bucket housed in a sealed cabinet below. Everytime I mill, I wipe down the top surfaces of the mill cabinet and shop vac. the lower compartment. I plan on simply placing a garbage bad over the control panel above while milling, so I don't anticipate any issues.

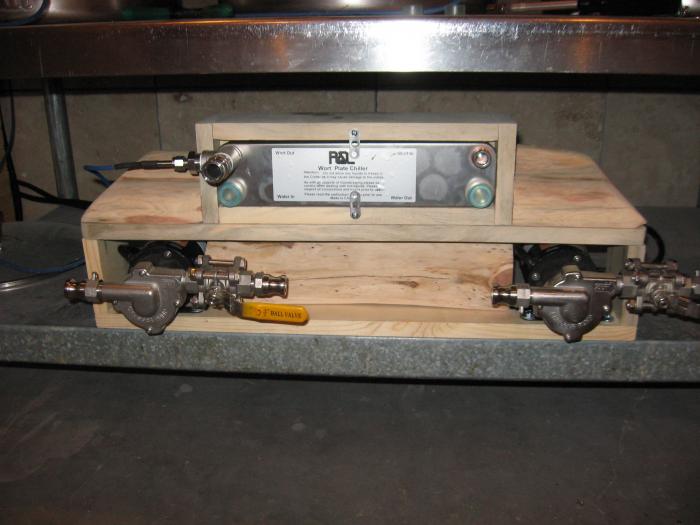

I have a full thread devoted to the grain mill build, as well as the fermentation chambers. Check out my signature line and you will find the links. The chamber thread explains my cooling sources in both chambers.

The ejector pump works great. It has made life so much easier having a big deep well sink with a drip pan and pre-rinse faucet. Clean up is much quicker.

Hey BadNewBrewery......I'm getting to it! I am having a pool installed, so all of my time has been devoted to that project. Don't worry though....I continue to brew the "old fashion" way with my other system, so the pipeline is full.

WOW! This looks amazing!! I am very envious of this! I started homebrewing wine and after being pretty successful at that my interest has shifted gears a little into all grain! I skipped extract. I tried a Mr. Beer kit once and hated it! I have been pretty cheap with my all grain equipment. ( I made a mash tun out of a cooler) :rockin: Some day I would love to be able to have a brewery like this in my basement! You are quite the carpenter! Nice work man!

Looking awesome man!

This has come a LONG way. Are you going to live-stream your first brew session? Or, maybe the third or fourth - once you get the bugs worked out?

Dude! I'm not that high tech.....I wouldn't have the slightest clue how to do that.Maybe you and Chip could take a little road trip to Michigan....it's only 750 or so miles! Shoot a little video of my set up in action (if it ever gets done!), tour, and showcase some of the great breweries in my state, etc. Sounds like a great episode 25 for C&B.....make it happen brotha!

Seriously, I don't anticipate the first go round with this system to go too smoothly, so it would probably be a live stream of me swearing and thowing sh*t. Maybe someday I'll post a video, but not until I have a few batches through it.

I just drank 3 cups of coffee spending my Sunday morning reading about this! Awesome build and thanks for reminding us that we all have lives outside of brewing and it can take time to build what YOU want.

The question is, how did the first brew day go!?! I'm only a short distance from you, and know the pool days are about overget to brewing!

I was still swearing after 4-5 batches on my new eherms system

cheez said:I was still swearing after 4-5 batches on my new eherms system

Enter your email address to join: