40ozBreWing

BW

- Joined

- Jul 11, 2017

- Messages

- 19

- Reaction score

- 0

Hello all, I am hoping you guys and gals can help me. I am relatively new to brewing and brewed up my 3rd batch a few weeks back. The style I was / am going for is a session style IPA; Founders All Day IPA being my inspiration.

Here are the particulars from my brew / beer:

Boil Size 6.5 gals; Batch size 5.1 gallons; OG – 1.043; FG – 1.006; ABV – 4.86; IBU – 57; BU:GU – 1.3

I used Wyeast 1056 smack pack for fermentation but since I was 1. Short 60 billion yeast cells (per calculations), and 2. was concerned with getting a FG that would still yield me close to 5% beer, I went ahead and added another ¼ of a packet of Safale-005 dry yeast to the mix, when I pitched the Wyeast.

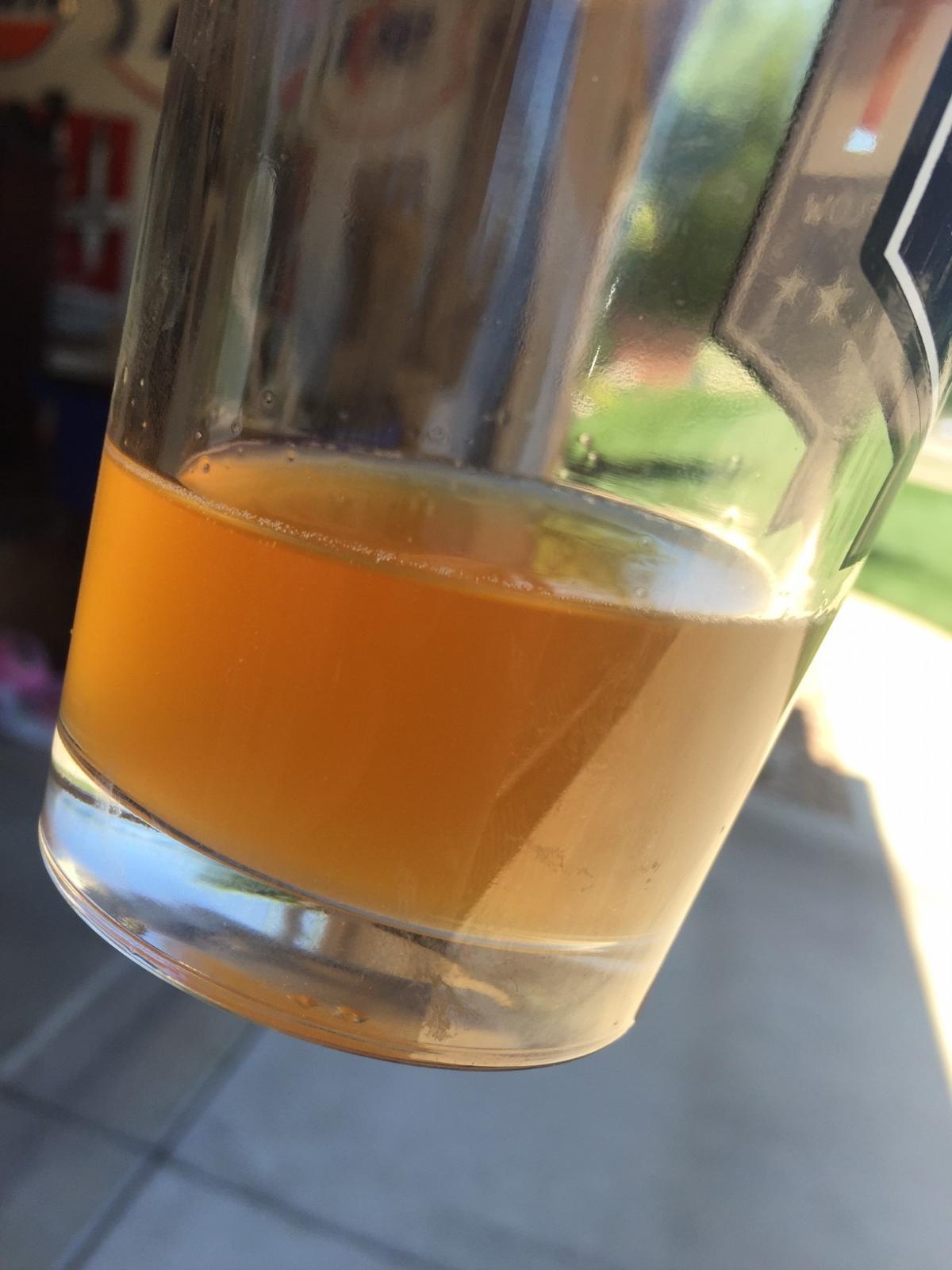

Here was my process, I brewed on 6/23 and 5 days later I had reached the FG of 1.006, confirmed by SG tests with the hydrometer (I know this because I checked the next few days and the gravity was the same). On July 1, I went ahead and racked to secondary, for further ‘clearing’ of the beer, being careful not to splash or introduce any oxygen during the transfer. It was at this time I took the liberty to taste my creation and it was OUTSTANDING! It was just what I was going for; great flavor, beautiful color and great hop aroma and flavor (some of which I attribute to the hopback I built and used).

So, since I was busy, I did not actually dry hop in the secondary until the 5th of July. I let it dry hop for 5 days and bottled on the 10th.

HEREIN LIES MY ISSUE AND CONCERN. When me and my brew buddy racked from the carboy to the bottling bucket we of course took a sample to taste……..and it was not the same beer I tasted when I racked to secondary. The beer wasn’t as near as “bright” and fresh tasting; it wasn’t as aromatic and tasteful as it was the first time I tasted it, when I racked to the secondary. I devised a rockin’ recipe that, upon first taste was exactly what I wanted, but upon tasting it prior to bottling everything was more ‘muted’. Right now, until tasting the final bottled product, I am a little bummed.

MY QUESTION is am I just not being patient and worrying about nothing, with the idea that once the beer is carbonated the flavors will come back out again??? Or is there somewhere I went wrong? I was very careful to gently swirl the beer into the bottling bucket and priming sugar solution, and kept the hose submerged so, again, to eliminate as little oxygen introduction as possible. I am hoping that when I taste to final carbonated product that my worries were for not, but until then…..

I eagerly, and appreciatively await your thoughts, and responses. In the meantime, I am thinking the following. Perhaps you can comment on this as well. I plan to do this same exact recipe next time except I am considering the following. Once I have reached final gravity, in that 5 to 7 days, I will skip dry-hopping and bottle it while it is at its ‘freshest’. And/or once fermenting slows down, dry-hop in the primary for a few days and still be bottling 7 to 9 days after brew day (again, making sure that FG has been met first). Do you guys see any issue with this? Is it okay to bottle this soon after fermentation is complete?

Again, thank you very much in advance for any and all words of advice or encouragement!!! The brewing bug has it hooks deep in me!

BW

Here are the particulars from my brew / beer:

Boil Size 6.5 gals; Batch size 5.1 gallons; OG – 1.043; FG – 1.006; ABV – 4.86; IBU – 57; BU:GU – 1.3

I used Wyeast 1056 smack pack for fermentation but since I was 1. Short 60 billion yeast cells (per calculations), and 2. was concerned with getting a FG that would still yield me close to 5% beer, I went ahead and added another ¼ of a packet of Safale-005 dry yeast to the mix, when I pitched the Wyeast.

Here was my process, I brewed on 6/23 and 5 days later I had reached the FG of 1.006, confirmed by SG tests with the hydrometer (I know this because I checked the next few days and the gravity was the same). On July 1, I went ahead and racked to secondary, for further ‘clearing’ of the beer, being careful not to splash or introduce any oxygen during the transfer. It was at this time I took the liberty to taste my creation and it was OUTSTANDING! It was just what I was going for; great flavor, beautiful color and great hop aroma and flavor (some of which I attribute to the hopback I built and used).

So, since I was busy, I did not actually dry hop in the secondary until the 5th of July. I let it dry hop for 5 days and bottled on the 10th.

HEREIN LIES MY ISSUE AND CONCERN. When me and my brew buddy racked from the carboy to the bottling bucket we of course took a sample to taste……..and it was not the same beer I tasted when I racked to secondary. The beer wasn’t as near as “bright” and fresh tasting; it wasn’t as aromatic and tasteful as it was the first time I tasted it, when I racked to the secondary. I devised a rockin’ recipe that, upon first taste was exactly what I wanted, but upon tasting it prior to bottling everything was more ‘muted’. Right now, until tasting the final bottled product, I am a little bummed.

MY QUESTION is am I just not being patient and worrying about nothing, with the idea that once the beer is carbonated the flavors will come back out again??? Or is there somewhere I went wrong? I was very careful to gently swirl the beer into the bottling bucket and priming sugar solution, and kept the hose submerged so, again, to eliminate as little oxygen introduction as possible. I am hoping that when I taste to final carbonated product that my worries were for not, but until then…..

I eagerly, and appreciatively await your thoughts, and responses. In the meantime, I am thinking the following. Perhaps you can comment on this as well. I plan to do this same exact recipe next time except I am considering the following. Once I have reached final gravity, in that 5 to 7 days, I will skip dry-hopping and bottle it while it is at its ‘freshest’. And/or once fermenting slows down, dry-hop in the primary for a few days and still be bottling 7 to 9 days after brew day (again, making sure that FG has been met first). Do you guys see any issue with this? Is it okay to bottle this soon after fermentation is complete?

Again, thank you very much in advance for any and all words of advice or encouragement!!! The brewing bug has it hooks deep in me!

BW