Thanks.

I live in FL. Lots of humidity. A/C indoors though, but as you mentioned, SWMBO will probably not tolerate hop drying smell (does it really smell?) indoors.

I have a basement area, which has AC but no air return, so little air changes in the room. Some leaks out when you open the doors, and through the crack.

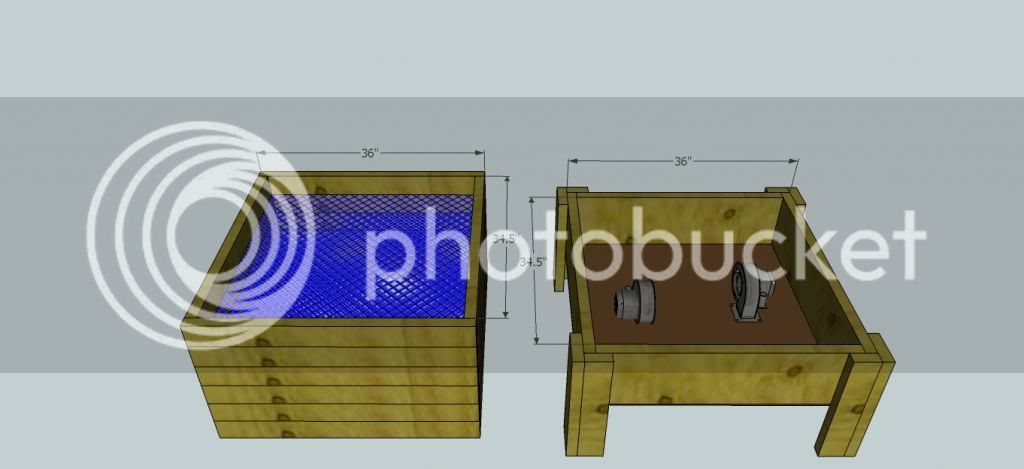

Have an old box fan and some scrap wood, could probably pick up some screen from home despot, and fashion a drying box. Do you think would be better to use outside in the high humidity, or inside in basement with low humidity but little airflow aside from incoming AC?

If outdoors, I could run some lizard heating cord (25watt) not supposed to get above 90" and I could throw a temp controller on it, and incorporate into the box design to warm the air? Doubtful that would do much outdoors to alter the RH much to make a difference, and just add complexity to the design.

Do you think I'd need a speed controller aside from the high-medium-low setting to adjust the fan speed?

Last year I dried in the oven with the oven light as heat source and the convection fan on. Got super hot because I didn't realize its a halogen light..... Haven't used those hops yet. Got a little over 1 oz last year. I only have four plants.

TD

Sent from my iPad using Home Brew