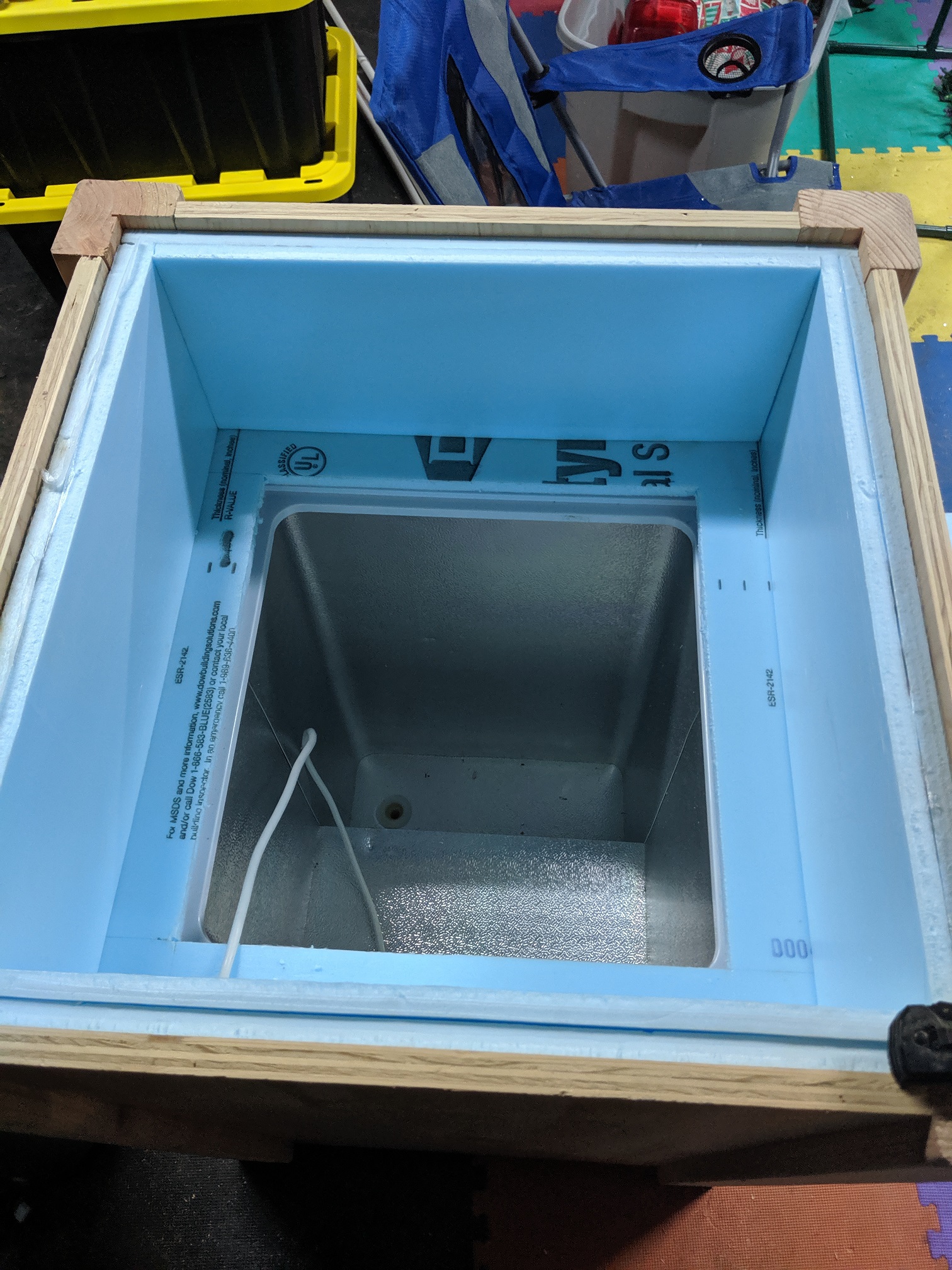

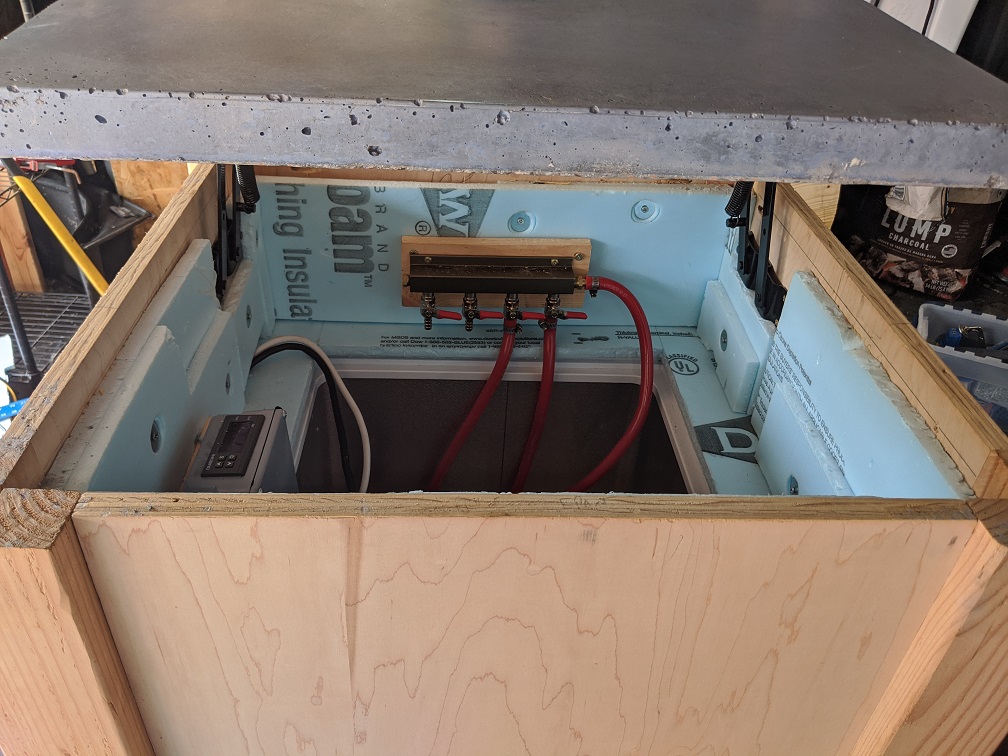

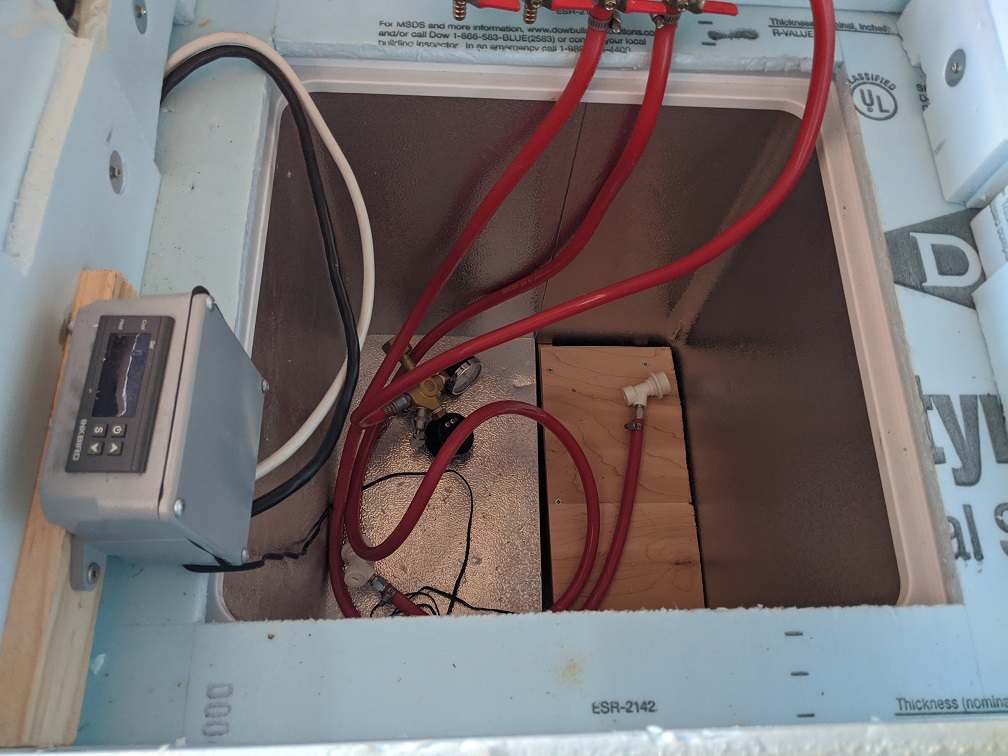

After a move from WNY to Katy Texas 2 years ago I am finally getting back to brewing!!! An important step is wrapping up, my new kegerator is finally getting finished!

The design was a mesh of a few things from the forums, with modifications to limited location/size/etc. In order to get it inside the house it had to be a "furniture style" build, and match the inside decor enough to fit in.

I know everyone including myself loves to cruise through pics of build, so here it goes!

The design was a mesh of a few things from the forums, with modifications to limited location/size/etc. In order to get it inside the house it had to be a "furniture style" build, and match the inside decor enough to fit in.

I know everyone including myself loves to cruise through pics of build, so here it goes!