Not sure how permanent the permanent marker will be on this plastic, but works for now...

Could use a paint marker too. I figured if it rubs off, its pretty easy to redo. It definitely makes it easier to read the markings. Stand looks good.

Not sure how permanent the permanent marker will be on this plastic, but works for now...

Any thoughts on how a raised 5 gallon bucket might work out as a stand? I'm thinking a bucket with a hole in the bottom big enough to fit the collection ball through sitting on a couple of wood blocks. Standard bucket diameters I've seen are around 12" which looks like it might sit right below the thermowell...

The only thing I haven't worked out very well is how to drain it into a keg, given that it is so low. How are it others planning to do this? I considered putting a second bracket on the wall or free standing that would be tall enough to put the keg under. That would mean I would have to lift it into the high stand, but I already lug around carboys so maybe it doesn't matter much.

From the bottom of the ball to the mounting studs (which I think is the widest point) is 24 inches.

Anyone put any thought into how to attach a CO2 line to this thing for pushing beer or feeding co2 while cooling the finished beer down? I like the idea of just putting a ball lock connector on the hose and connecting it to the keg and pushing the beer over rather than picking stuff up and moving it around.

I was not planning to reattach the ball after primary. I think the oxygen pickup would be worse than any benefit.

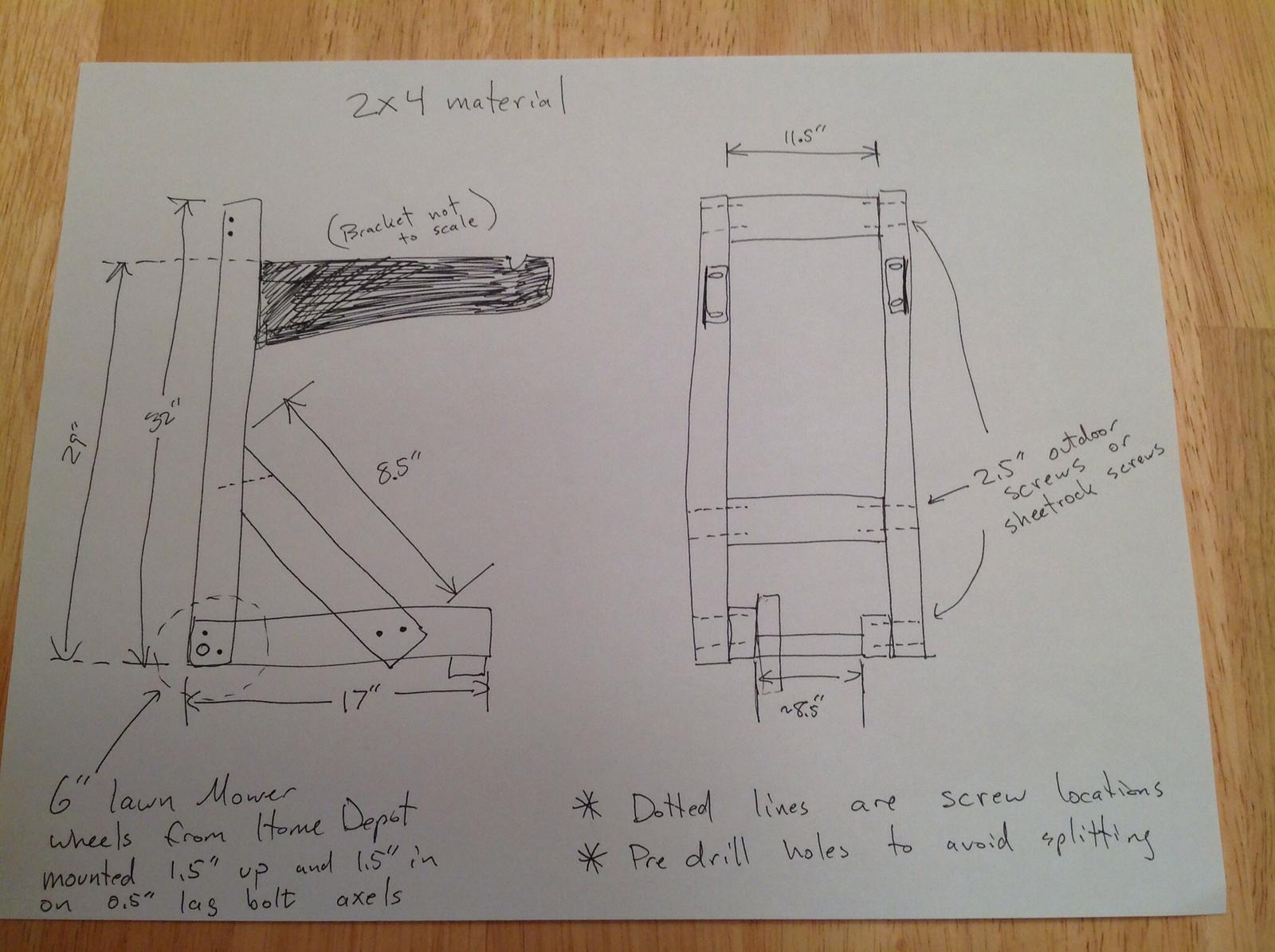

Here is a picture of the stand I threw together quickly for it. I have a heating pad strapped to it and the probe from an STC-1000 controller in the thermowell.

I Like the mobile stand!

Still waiting here in Texas. I sent them an email last week when I started seeing people on here get deliveries, they replied that all orders had been shipped and ups was dealing with a lot of packages and would send me a notification. A week later still nothing.

I sent them another email this morning telling them still no product or notification but I have not heard back yet.

Now they have changed shippers here in Canada and are sending out via FEDEX. Unfortunately for me I will be away when they arrive. Hopefully they'll be here when I come back as I'm getting quite antsy.

Sent from my iPad using Home Brew

The only thing I haven't worked out very well is how to drain it into a keg, given that it is so low. How are it others planning to do this? I considered putting a second bracket on the wall or free standing that would be tall enough to put the keg under. That would mean I would have to lift it into the high stand, but I already lug around carboys so maybe it doesn't matter much.

So I put my first batch in the conical last night and pitched this morning. This evening, there is a steady stream of bubbles coming up and breaking on the surface of the wort ( it looks like the ferment is starting either in the ball at the bottom or at the bottom of the cone).

So far, it seems pretty nice however I do have a bit of confusion. There is no airlock activity at all, but the top is screwed on tight ( and the gasket is in there). Has anyone else started fermenting in it and have you had any issues getting the top to seal up? Given the stream of bubbles, the gas is getting out somewhere and around the top is pretty much the only other option.

On a totally separate note, looking at the. Fermenter with the heating pad working, got me thinking that the fluid in the ball is probably at a notably different temperature. Maybe in the future I will keep the valve closed until after growth is over and then open it so the yeast is at a more uniform temperature ( yes, this will put some O2 into it when the air bubbles up, but that should be scrubbed right out by the yeast ).

One other thing I did was to out the wort in there and then wait 10 hours or so for the grub/break/hop material to settle into the ball and then removed it before aerating and pitching. Seems better to get that stuff out if there to begin with so the harvested yeast later is cleaner.

...A gasketed lid should not need teflon tape. I do not think that your lid is screwing on completely. I will say I am looking for a better gasket material though. The super thin white foam just isnt going to cut it for me.

Still no reply to previous email. I have sent another, asking for for my shipping information.

Hopefully I will hear something soon.

Just wanted to say thanks for all the reviews on here. Keep them coming. It sounds like a great product so far and I'm really enjoying the information/tips/complaints before I grab one up. The cost savings on this product versus a stainless conical fermenter seem quite obvious. Cool product. Cheers to the folks who designed it.

Just sanitized my fermenter for tomorrow and here is what I noticed.

Clean it out a few days before you want to use it, it's actually pretty clean, but a little stuff from manufacturing needs to be washed out.

Try to clean the threads on the lid with a knife or sand paper or whatever you can use will help make it easy to thread on.

I have done plumbing work before, but for those who haven't, using Teflon tape the correct way will save you tape and many headaches. Wrap the tape in the direction of the threads. I.e. The tape should wrap in the same direction as what screws onto the threads.

Use more tape than usual. I have been taught one wrap is enough. I noticed with these, wrap it up a little thicker and a much better seal is achieved.

Only wrap the threads on the fermenter. Teflon tape on white plastic, not on gray. You don't wrap threads on a union. It has a gasket seal.

Wrap Teflon tape on threads for the lid and you will get a great seal.

After you rack the beer to the fermenter, let it sit awhile before pitching yeast so you can dump the trub from collection ball and have an easier time re harvesting yeast.

Remove the airlock before opening valve on the collection ball to prevent sucking in the air lock water.

That is all I have. Other uses please let me know if anything I said is wrong, I will correct it to keep others from making the same mistake. I love this thing so far!

Sent from my iPad using Home Brew

Are you going to run it out through the hose attachment? If you dump the stuff in the ball and reattach you will get a lot of o2 going up though the beer when you reopen the valve. I don't know how much it would really matter, but it is a bit sub optimal.

Enter your email address to join: