OK Jay,

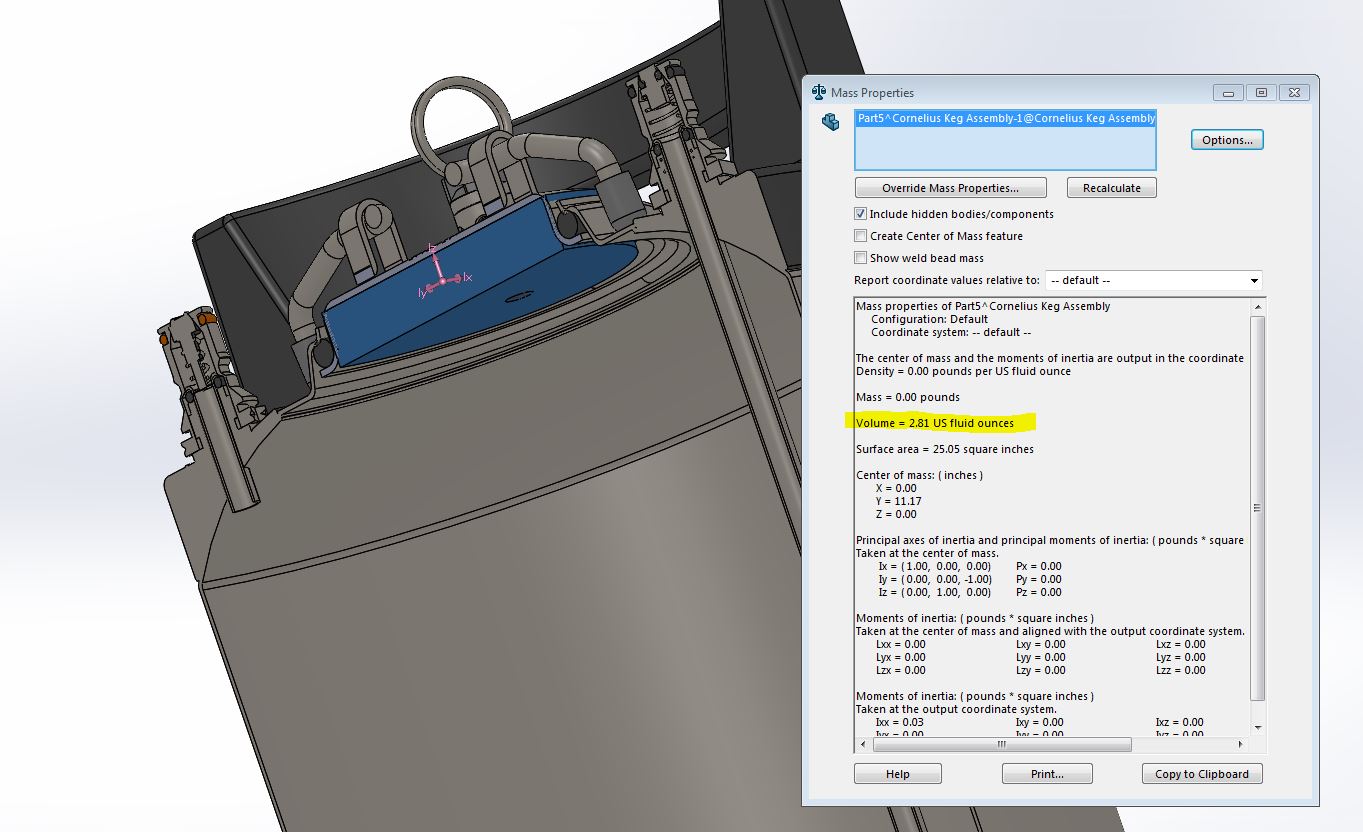

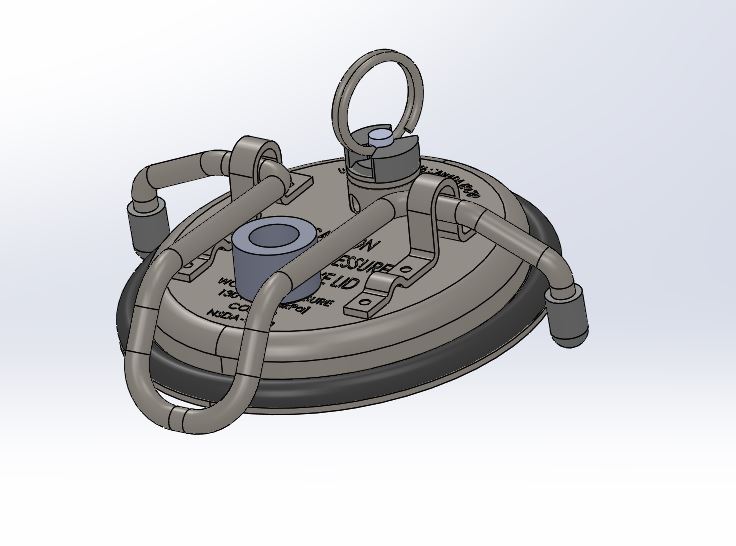

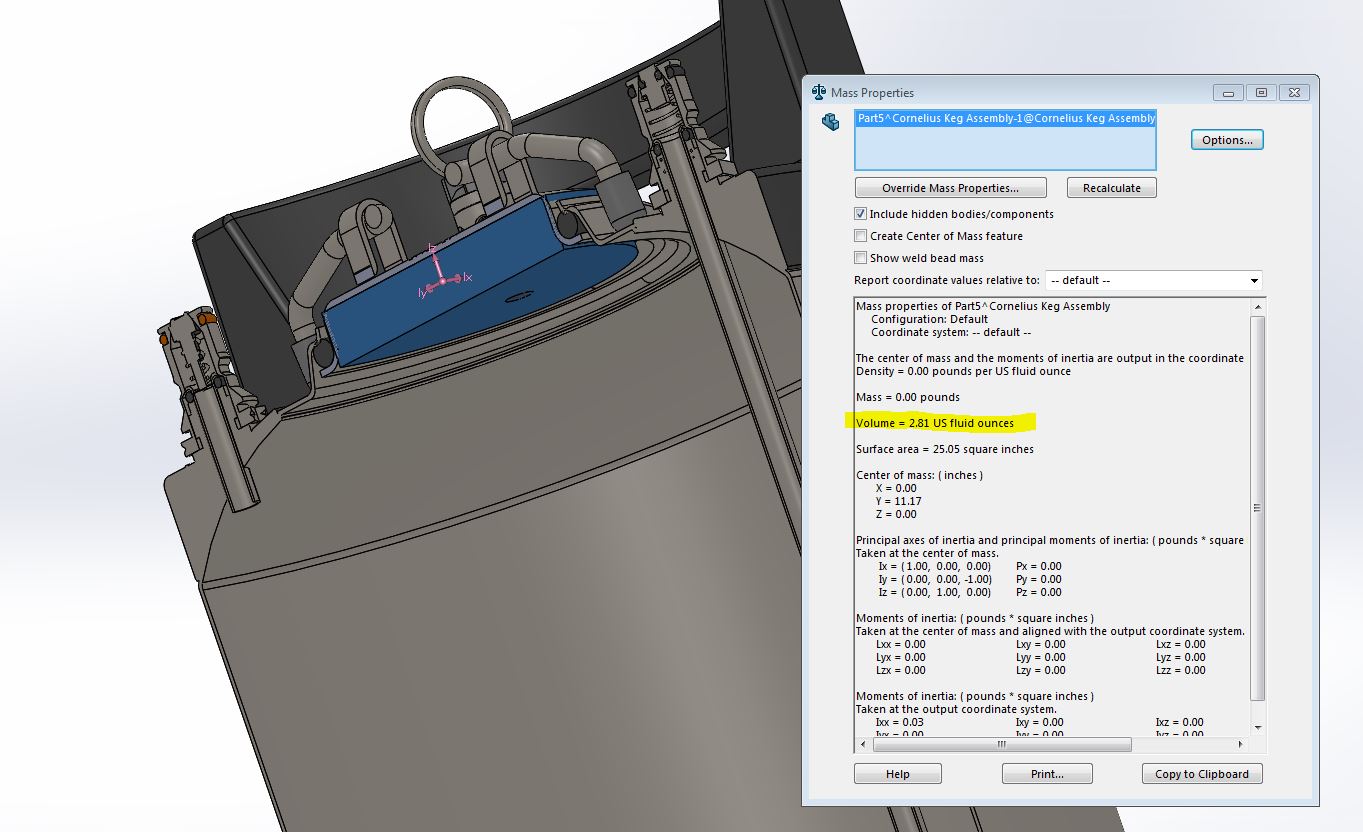

Looking at the quality, complexity and cost of the other items here I have something for you to look at. A lot of people are using corny kegs and are attempting to limit oxygen uptake at all stages post fermentation. The most common way to "purge" a keg is to fill it with a StarSan solution and then push this solution through the outlet post. However, due to the physical design of the lid approximately 2 floz of air cannot be purged from inside of the pressure relief on the keg lid, as shown below. This 2 oz is WAY above the recommended O2 levels at packaging.

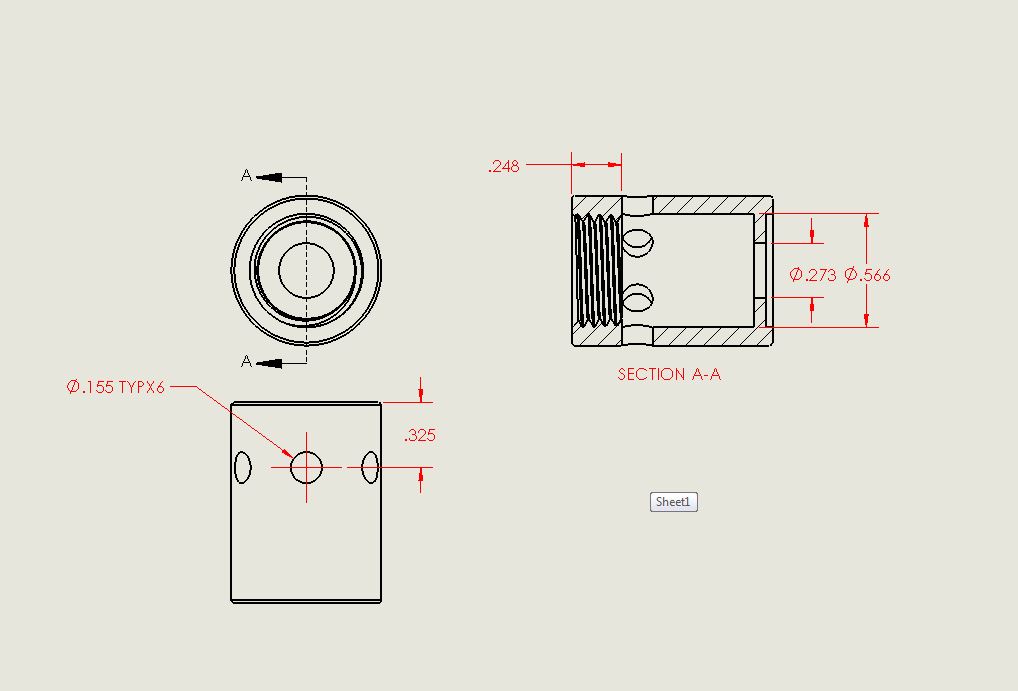

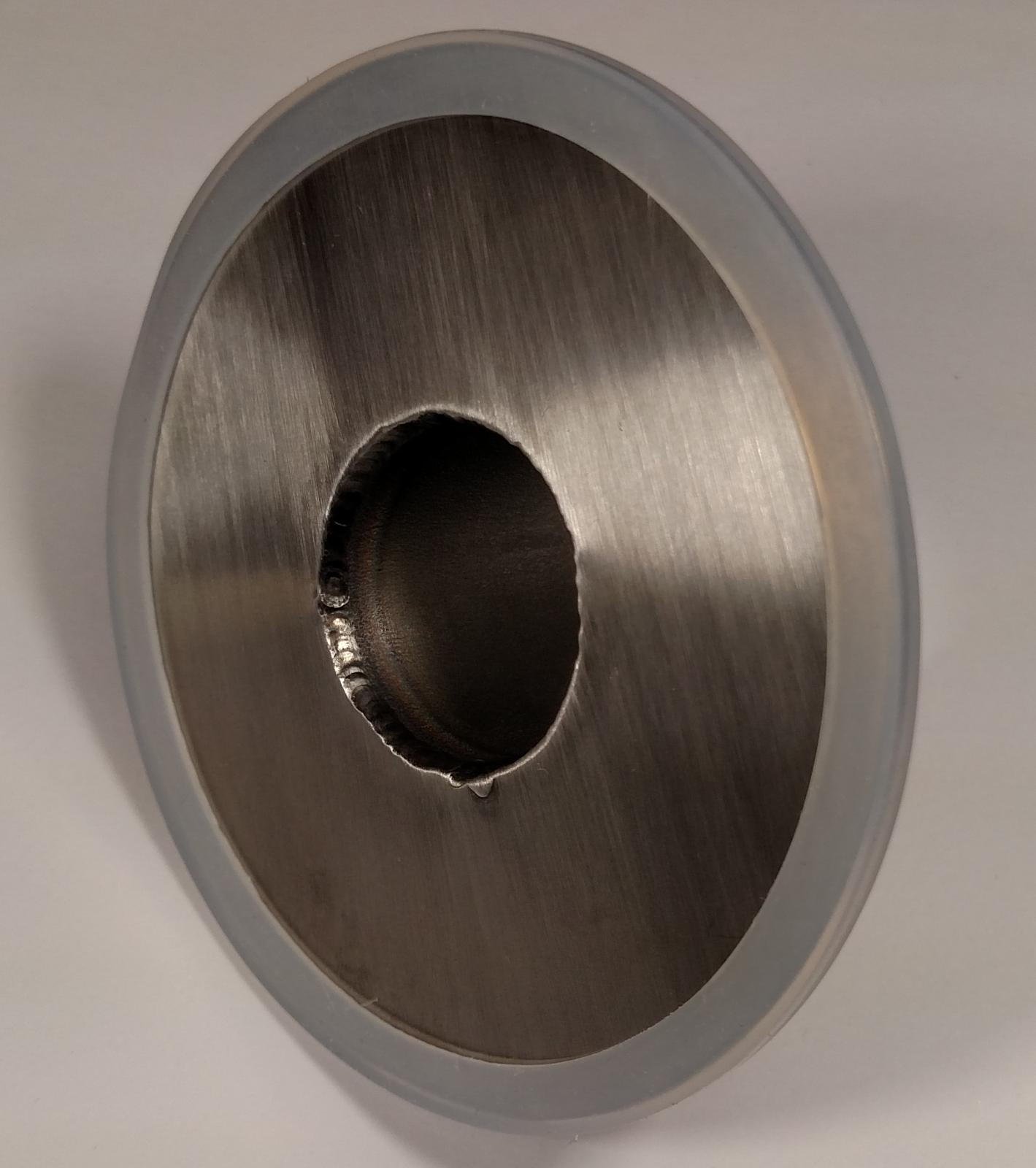

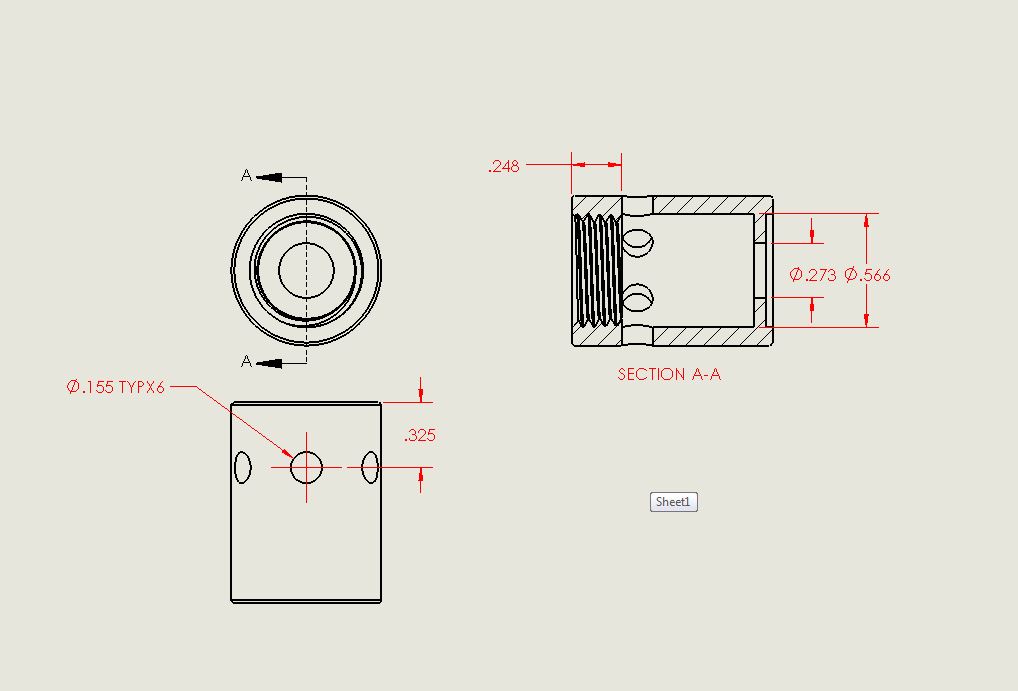

My thought is to drill out the cast pressure relief and replace it with a welded on 1/4" coupling. The coupling would have to be modified by, removing some of the threading, drilling the relief holes, adding a section of sheet/washer/ect to hold the spring compressed. Off some quick measurements we would be looking like something below.

Do you think this is economically feasible?

Looking at the quality, complexity and cost of the other items here I have something for you to look at. A lot of people are using corny kegs and are attempting to limit oxygen uptake at all stages post fermentation. The most common way to "purge" a keg is to fill it with a StarSan solution and then push this solution through the outlet post. However, due to the physical design of the lid approximately 2 floz of air cannot be purged from inside of the pressure relief on the keg lid, as shown below. This 2 oz is WAY above the recommended O2 levels at packaging.

My thought is to drill out the cast pressure relief and replace it with a welded on 1/4" coupling. The coupling would have to be modified by, removing some of the threading, drilling the relief holes, adding a section of sheet/washer/ect to hold the spring compressed. Off some quick measurements we would be looking like something below.

Do you think this is economically feasible?