- Joined

- Mar 10, 2021

- Messages

- 2,719

- Reaction score

- 2,343

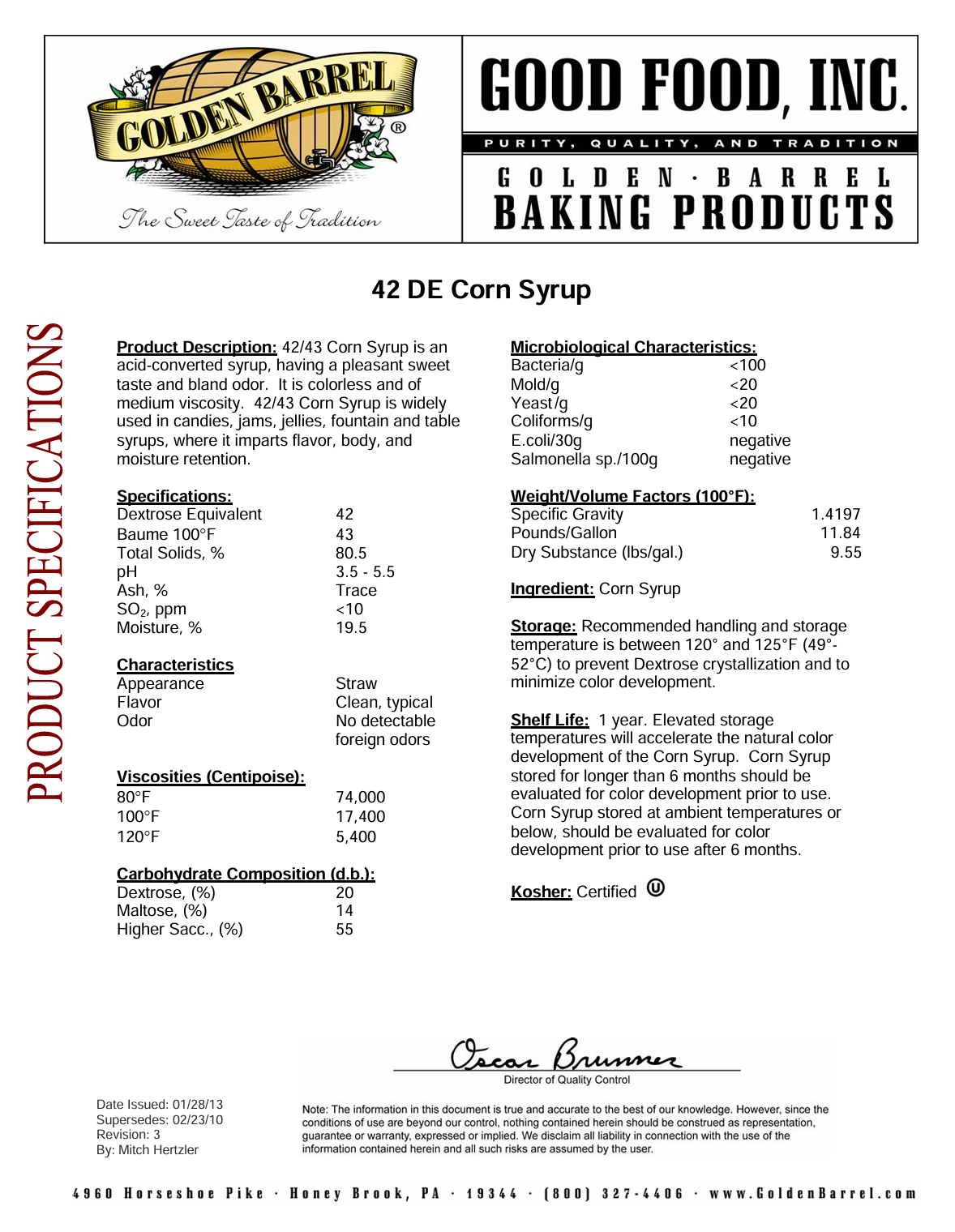

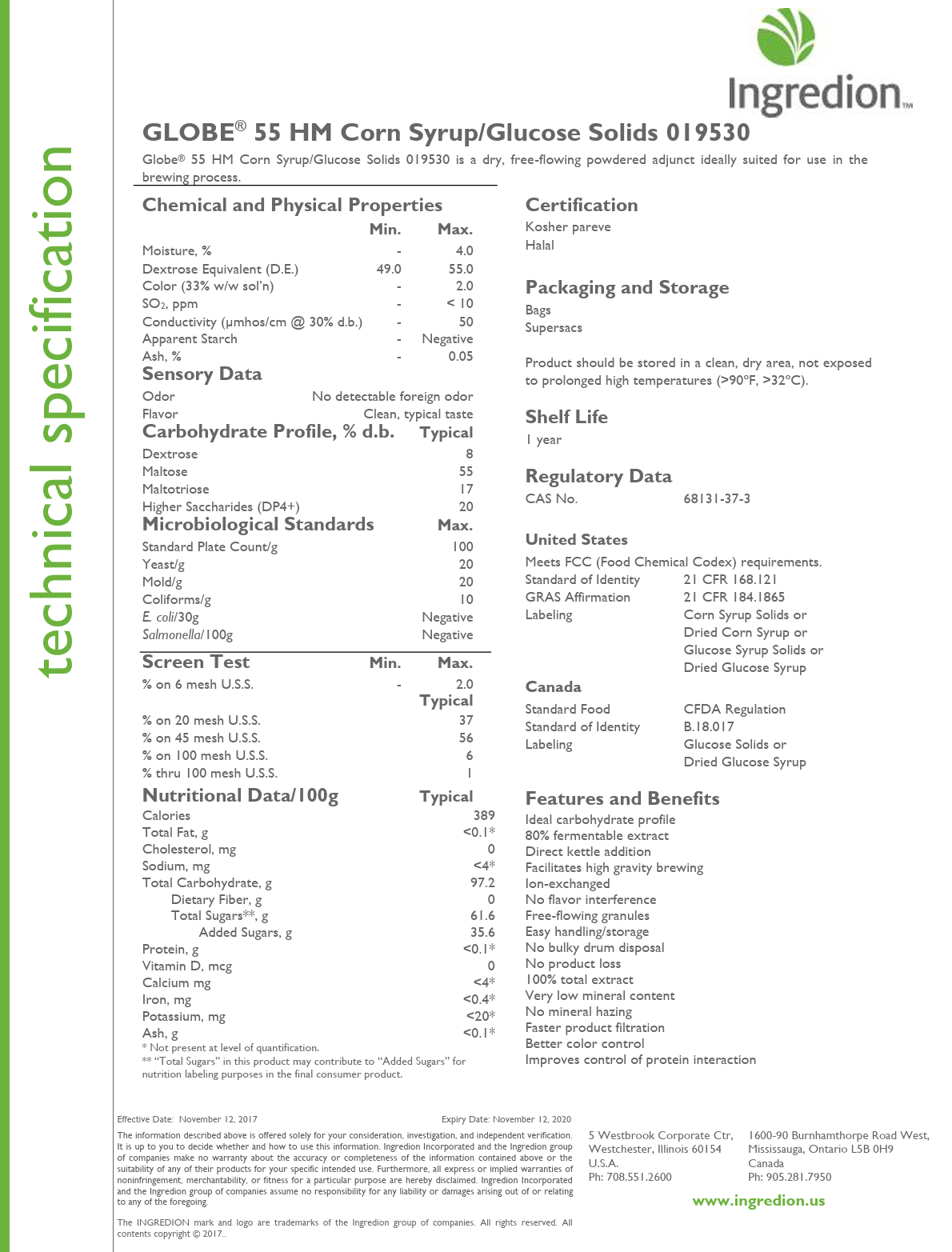

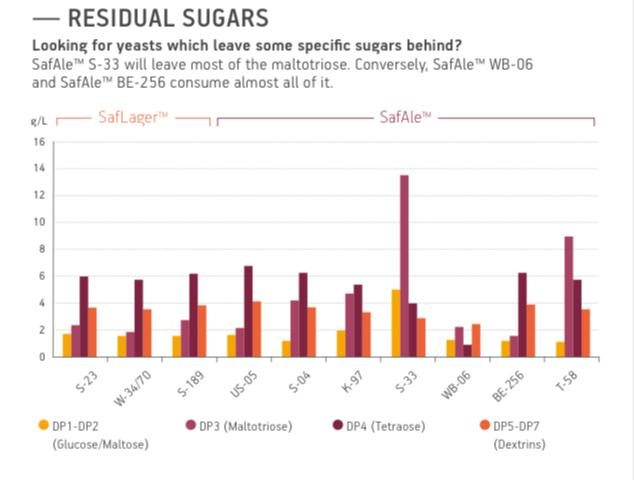

All the different beer flavors and body depend on the different combinations of all of these types of sugars. Including the oligosaccharides. If all of that were the same, then we'd not be having dry beers and sweeter beers. They'd all be the same in that respect.Maybe different brands of corn syrup have different levels of conversion (and sugars), whereas HFCS would be converted more fully.

Do yeast readily ferment "glucose, maltose and higher oligosaccharides,..."?

It's the oligosaccharides that would probably cause problems.

Different yeasts will ferment and not ferment to varying extents those same sugars too. So don't let your science get in the way of the craftsmanship you also need to put into your beers.