You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cheap compact wort pump

- Thread starter ColonelPanic

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

No pump works well with boiling water, most will cavitate, some more, some less. Once the bubbles stop in your boil, then pumps start to work well again.

Murphys_Law

Well-Known Member

I start my pump with about 1 or 2 mins left in the boil to clean everything and never had an issue.

That's what I was hoping to do. Is your pump working just as good when the water is boiling? I tested it again yesterday and the water had to cool down for about 5 min before the pump worked normally.I start my pump with about 1 or 2 mins left in the boil to clean everything and never had an issue.

Murphys_Law

Well-Known Member

Every once in awhile I have to unplug the pump and close/open the valve and turn the pump back on but thats rare

augiedoggy

Well-Known Member

The plastic around the magnet can warp with prolonged pumping of boiling liquid.. I seized one of mine this way pumping boiling pbw.... 200 degree liquid will sanitize and clean just as well as boiling liquid.. there's not actual need to recirculate boiling liquid.

TANSTAAFB

Well-Known Member

Just got mine going! Worked flawlessly in a test brew. This is the aggie engineered version. I got my cam x female npt fitting today but forgot to take a pic. This thing is SOOOOO much smaller, quieter, cheaper, and less finicky than my Chugger!

View attachment 1509748962496.jpg

View attachment 1509748962496.jpg

I’ve been using one of these pumps and the power supply went out today. The light on it cycles on and off, you can hear a capacitor whine with it. I’m using one of the supplies similar to the below 24v 3a version. Speed is controlled with a PWM dc motor speed controller.

The first one I got was dead on arrival with the same symptoms. Has anyone else had problems?

https://m.ebay.com/itm/5V-12V-24V-D...hash=item5444647aab:m:mRW8TEiRdl0V3gK_0ViHKSA

The first one I got was dead on arrival with the same symptoms. Has anyone else had problems?

https://m.ebay.com/itm/5V-12V-24V-D...hash=item5444647aab:m:mRW8TEiRdl0V3gK_0ViHKSA

augiedoggy

Well-Known Member

I shorted mine out and blew it unfortunately so switched to a different dc powersupply I salvaged from and old xerox machine being scrapped... havent had any issues with that.Ive been using one of these pumps and the power supply went out today. The light on it cycles on and off, you can hear a capacitor whine with it. Im using one of the supplies similar to the below 24v 3a version. Speed is controlled with a PWM dc motor speed controller.

The first one I got was dead on arrival with the same symptoms. Has anyone else had problems?

https://m.ebay.com/itm/5V-12V-24V-D...hash=item5444647aab:m:mRW8TEiRdl0V3gK_0ViHKSA

I did however have problems with another 24v dc power supply on my fermenter control panel start causing some sort of electrical noise which is causing the temp probes to read erratically and even caused my arduino to lose communication.

TANSTAAFB

Well-Known Member

I purchased mine from Bayite on Amazon. Had a small leak where the body and the head meet. I had it oriented with the discharge down so it rook me a while to figure out where it was coming from. I responded to the email they sent me asking about my purchase experience. Was expecting a hassle, return, wait, etc. They said this kind of issue is rare and shipped me a new pump ASAP w/o needing to return the old one. Excellent customer service!

bayite BYT-7A015 DC 12V Solar Hot Water Heater Circulation Pump with DC Power Supply Adapter Low Noise 3M Head 8LPM 2.1GPM https://www.amazon.com/dp/B01G305PK0/?tag=skimlinks_replacement-20

bayite BYT-7A015 DC 12V Solar Hot Water Heater Circulation Pump with DC Power Supply Adapter Low Noise 3M Head 8LPM 2.1GPM https://www.amazon.com/dp/B01G305PK0/?tag=skimlinks_replacement-20

Last edited by a moderator:

augiedoggy

Well-Known Member

sounds like the silicone oring is at fault that seals the head cover... might be worth looking at.I purchased mine from Bayite on Amazon. Had a small leak where the body and the head meet. I had it oriented with the discharge down so it rook me a while to figure out where it was coming from. I responded to the email they sent me asking about my purchase experience. Was expecting a hassle, return, wait, etc. They said this kind of issue is rare and shipped me a new pump ASAP w/o needing to return the old one. Excellent customer service!

bayite BYT-7A015 DC 12V Solar Hot Water Heater Circulation Pump with DC Power Supply Adapter Low Noise 3M Head 8LPM 2.1GPM https://www.amazon.com/dp/B01G305PK0/?tag=skimlinks_replacement-20

Last edited by a moderator:

nealm

Well-Known Member

+1 on that. Happened to me once.

They are clear silicone and easy to miss.

They are clear silicone and easy to miss.

TANSTAAFB

Well-Known Member

Good to know! New pump arrived in 2 days...I REALLY appreciate good customer service, it's becoming a rare commodity

LittlejohnBrew

Well-Known Member

- Joined

- May 2, 2017

- Messages

- 88

- Reaction score

- 23

Does someone have a guide to disassemble the tan pumps? My impeller wasn't rotating and upon removal of the volute found the shaft siezed. Some gunk came out so appears it was likely due to trub making its way into the pump shaft. I attempted to disassemble and unfortunately broke the plastic shaft. Plan on getting a replacement and would like to know how you guys are disassembling for future reference. Or are these just not disassembly friendly?

EDIT: after further disassembly it appears I may have a direct drive pump. I've yet to get it fully disassembled, but there appears to be oil coming from one of the bearings (?). It at least smells like oil which i wouldn't expect from a magnetic drive. What product are you guys using for 24V magnetic drive pumps?

EDIT: after further disassembly it appears I may have a direct drive pump. I've yet to get it fully disassembled, but there appears to be oil coming from one of the bearings (?). It at least smells like oil which i wouldn't expect from a magnetic drive. What product are you guys using for 24V magnetic drive pumps?

Last edited:

augiedoggy

Well-Known Member

Remove 4 screws, pop off head then pull impeller shaft out it's held in the home by magnetic force.

augiedoggy

Well-Known Member

Btw the shaft is ceramic not plastic

augiedoggy

Well-Known Member

Not sure what's happening with the forum but my response disappeared. Time disassemble you remove 4 screws pop off head and pull impeller straight out. It should just be held in by magnetic force unless the pump overheated and the plastic casing around the magnet warped I had that happen myself after trying to pump boiling liquid for a while.

nealm

Well-Known Member

Auggie

I had a different experience with one of these 24v pumps locking up. It happened while pumping 170f liquid. The problem I believe occurred when I was pumping at a slow rate with a switch maintaining the liquid level. I was not paying attention and the pump failed to restart but the power was still on. It sat this way for about a half hour before I noticed but when I turned up the speed the pump didn't start and I noticed the pump was quite hot. When I took it apart the magnet had seized. I think what happened is the stalled pump overheated electrically causing the casing to swell as you suggested.

I have used these pumps to move boiling wort intermittently without problem, though I have not done it on a continuous basis.

Another observation regards the cleaning of these pumps. I had at first rinsed the pumps out by shooting water through them in the reverse direction. I found that this didn't clean behind the ss plate adequately and the bearing behind the plate could become jammed with dried up wort. I now add a step where I recirculate cleaning solution and rinse water for extended periods as part of my post brewing cleanup.

My system is a Brutus 20 two vessel system and I use the pump to recirculate the wort between the kettle and the MT before draining it a into the BK

I had a different experience with one of these 24v pumps locking up. It happened while pumping 170f liquid. The problem I believe occurred when I was pumping at a slow rate with a switch maintaining the liquid level. I was not paying attention and the pump failed to restart but the power was still on. It sat this way for about a half hour before I noticed but when I turned up the speed the pump didn't start and I noticed the pump was quite hot. When I took it apart the magnet had seized. I think what happened is the stalled pump overheated electrically causing the casing to swell as you suggested.

I have used these pumps to move boiling wort intermittently without problem, though I have not done it on a continuous basis.

Another observation regards the cleaning of these pumps. I had at first rinsed the pumps out by shooting water through them in the reverse direction. I found that this didn't clean behind the ss plate adequately and the bearing behind the plate could become jammed with dried up wort. I now add a step where I recirculate cleaning solution and rinse water for extended periods as part of my post brewing cleanup.

My system is a Brutus 20 two vessel system and I use the pump to recirculate the wort between the kettle and the MT before draining it a into the BK

Earlier I posted that I thought the power supply went out. I was incorrect, power supply is fine but the pump is dead. When I have the pump disconnected I get 24v out of the power supply as expected. When I connect the pump nothing happens then a couple seconds later the power supply light will start to blink, I think something is shorted out.

I don't have another 24v source laying around but I connected 12V to the pump and it didn't run. I am assuming the pump would work but move slower on a reduced voltage like a small computer fan would.

I ended up getting ~10 brew days out of the pump before it broke.

I don't have another 24v source laying around but I connected 12V to the pump and it didn't run. I am assuming the pump would work but move slower on a reduced voltage like a small computer fan would.

I ended up getting ~10 brew days out of the pump before it broke.

Sounds like the motor winding enamel coating melted and shorted from prolonged over-heating...

LittlejohnBrew

Well-Known Member

- Joined

- May 2, 2017

- Messages

- 88

- Reaction score

- 23

I was mistaken when I thought these were mag drive pumps say like the mark II. Didn't really pay much attention that these are brushless motors with the impeller mounted directly on motor rotor.

Auggie/Nealm, that is what appears to have happened to mine. I also had my pump running at 170F for a 30 min whirlpool. I noticed after some time that there was no flow and discovered the motor to be extremely hot. When taking apart it was nearly impossible to remove the rotor magnet. When forcing the magnet out I noticed brown liquid which could be wort, but smelt like oil. Maybe it was just the smell from the burnt components.

Given that this failed below 170F I'm assuming it was due to trub getting into the magnet, causing it to sieze. No flow then caused the plastic components to overheat and melt.

What do you guys do to minimize trub to the pump/ I currently use a bazooka screen and a hop bag, but trub still makes it's way into the pump. I have also noticed that the motor gets extremely hot in normal use. Is this normal or do you guys do anything to keep the temperature down?

Auggie/Nealm, that is what appears to have happened to mine. I also had my pump running at 170F for a 30 min whirlpool. I noticed after some time that there was no flow and discovered the motor to be extremely hot. When taking apart it was nearly impossible to remove the rotor magnet. When forcing the magnet out I noticed brown liquid which could be wort, but smelt like oil. Maybe it was just the smell from the burnt components.

Given that this failed below 170F I'm assuming it was due to trub getting into the magnet, causing it to sieze. No flow then caused the plastic components to overheat and melt.

What do you guys do to minimize trub to the pump/ I currently use a bazooka screen and a hop bag, but trub still makes it's way into the pump. I have also noticed that the motor gets extremely hot in normal use. Is this normal or do you guys do anything to keep the temperature down?

augiedoggy

Well-Known Member

Sounds like Youany have seized it. The one I seized did the same thing...

I Have 3 12v versions of this pump I used for the first year and 5 24v versions of this pump including the one I seized. Running them dry or pumping boiling liquid can seize them up. Otherwise I probable got hundreds of hours of run time on the other 4 24v pumps I've been using for the last 3 years. And probably 60 brews or so on them so I know they do normally last a long time.

I Have 3 12v versions of this pump I used for the first year and 5 24v versions of this pump including the one I seized. Running them dry or pumping boiling liquid can seize them up. Otherwise I probable got hundreds of hours of run time on the other 4 24v pumps I've been using for the last 3 years. And probably 60 brews or so on them so I know they do normally last a long time.

augiedoggy

Well-Known Member

Little john, what power supply are you using? How many amps does it output? It is unusual for one of these to seize unless there's cavitation, or overheating. Also the pump shouldn't be getting any hotter than the liquid.. that's why I wonder about the power supply.

LittlejohnBrew

Well-Known Member

- Joined

- May 2, 2017

- Messages

- 88

- Reaction score

- 23

I bought this "24-Volt 2-Amp 48-Watt AC Adapter Transformer Power Supply 5mm DC Output Jack" off e-bay. However, the actual label says its 2.5A. Appears these tan pumps are rated up to 2A. I didn't notice this before and likely the issue of the excessive heat. Disappointing that I was shipped the incorrect power supply.

augiedoggy

Well-Known Member

That's not it.. it's a minimum of 2amps..I use a 7 amp supply to power all mine.

LittlejohnBrew

Well-Known Member

- Joined

- May 2, 2017

- Messages

- 88

- Reaction score

- 23

Just want to make sure we are talking about same pump. Link below says 48W, 24V 2A, but then says 1.8A max

https://m.ebay.com/itm/24V-Pure-Foo...323554&hash=item440df11eb2:g:HUwAAOSwKWRZ4CF5

https://m.ebay.com/itm/24V-Pure-Foo...323554&hash=item440df11eb2:g:HUwAAOSwKWRZ4CF5

Sounds like the motor winding enamel coating melted and shorted from prolonged over-heating...

I was recirculating boiling fluid so that fits the bill. I probably buy a new one for my HERMs when I finish it to recirc in the HLT. I’m going to get a chugger for the boil kettle so I can recirc boiling fluid.

LittlejohnBrew

Well-Known Member

- Joined

- May 2, 2017

- Messages

- 88

- Reaction score

- 23

After second thought the output amperage shouldn't matter. That's the max output, but the pump motor only draws 2A.

augiedoggy

Well-Known Member

yes same pumps .. they require 1.8a minimum power... They only use the amperage the Motor needs... You can power them with a 100amp supply and they will run the same as A 3 amp supply you can damage them with a power source capable of more amp than they need.. They do run better with a 3 amp suy than a 2 amp though because I've tried both.. The motor can draw more than 2 amps. And if your using one of those $3 cell phone style wall power adapters many of them don't actually put out the amps they advertise.. so you want to go with a bigger one. They also have a high failure rate compared to theore sophisticated power supplies.Just want to make sure we are talking about same pump. Link below says 48W, 24V 2A, but then says 1.8A max

https://m.ebay.com/itm/24V-Pure-Foo...323554&hash=item440df11eb2:g:HUwAAOSwKWRZ4CF5

augiedoggy

Well-Known Member

Why do you need to recirculate boiling liquid? It can cause cavitation that can damage any pump. As far as sanitation recicirculating the liquid once it's over 170 has the same effect .I was recirculating boiling fluid so that fits the bill. I probably buy a new one for my HERMs when I finish it to recirc in the HLT. I’m going to get a chugger for the boil kettle so I can recirc boiling fluid.

LittlejohnBrew

Well-Known Member

- Joined

- May 2, 2017

- Messages

- 88

- Reaction score

- 23

After second thought the output amperage shouldn't matter. That's the max output, but the pump motor only draws 2A.

yes same pumps .. they require 1.8a minimum power... They only use the amperage the Motor needs... You can power them with a 100amp supply and they will run the same as A 3 amp supply you can damage them with a power source capable of more amp than they need.. They do run better with a 3 amp suy than a 2 amp though because I've tried both.. The motor can draw more than 2 amps. And if your using one of those $3 cell phone style wall power adapters many of them don't actually put out the amps they advertise.. so you want to go with a bigger one. They also have a high failure rate compared to theore sophisticated power supplies.

Haha I just realized that and posted right before you did. Dunno what I was thinking before. Haven't had any issues yet with the power supply. Maybe I got a faulty pump? When I removed the motor from the housing the back of it was melted badly too (close to to where the wires go in) so it got hot as hell.

I am assuming these pumps rely on the wort to cool the pump and motor rotor? Once all the trub got into the bearing and magnet it probably locked up due to the friction then over heated. Could have been in this condition for 10+ mins as I started the pump and walked away.

That said what is the best way to strain the trub prior to pump suction? Right now I use a paint strainer bag for all hop additions and a bazooka screen upstream of the pump. The screen is almost always covered in a good bit of trub.

I'm considering installing a pickup tube that takes suction from the side of the kettle. Then cover the tube with a hot water heater SS hose. Maybe a 2ft hose so there is more surface area in case of clogging.

augiedoggy

Well-Known Member

Funny thing was I wrote that yesterday but just forgot to hit submit so it was still in my browser this morning. It could very well have been a faulty one. I had a 24v one that stuck from time to time so I took the impeller/magnet assembly from another 12v one I dropped and snapped the head off. That fixed it so I suspect they did a poor job coating that magnet evenly and it was rubbing.Haha I just realized that and posted right before you did. Dunno what I was thinking before. Haven't had any issues yet with the power supply. Maybe I got a faulty pump? When I removed the motor from the housing the back of it was melted badly too (close to to where the wires go in) so it got hot as hell.

I am assuming these pumps rely on the wort to cool the pump and motor rotor? Once all the trub got into the bearing and magnet it probably locked up due to the friction then over heated. Could have been in this condition for 10+ mins as I started the pump and walked away.

That said what is the best way to strain the trub prior to pump suction? Right now I use a paint strainer bag for all hop additions and a bazooka screen upstream of the pump. The screen is almost always covered in a good bit of trub.

I'm considering installing a pickup tube that takes suction from the side of the kettle. Then cover the tube with a hot water heater SS hose. Maybe a 2ft hose so there is more surface area in case of clogging.

Why do you need to recirculate boiling liquid? It can cause cavitation that can damage any pump. As far as sanitation recicirculating the liquid once it's over 170 has the same effect .

To sterilize the pump and plate chiller. I want to chill as fast as possible after the boil to limit DMS so I sterilize during the boil. I guess I could sterilize them as the boil is starting then leave them connected the whole time.

What is your workflow for sterilizing the pump and chiller at the end of the boil?

LittlejohnBrew

Well-Known Member

- Joined

- May 2, 2017

- Messages

- 88

- Reaction score

- 23

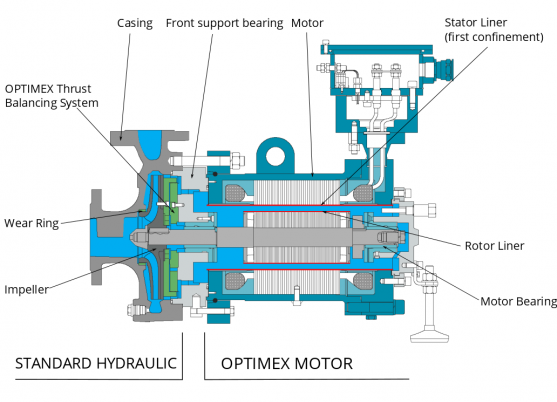

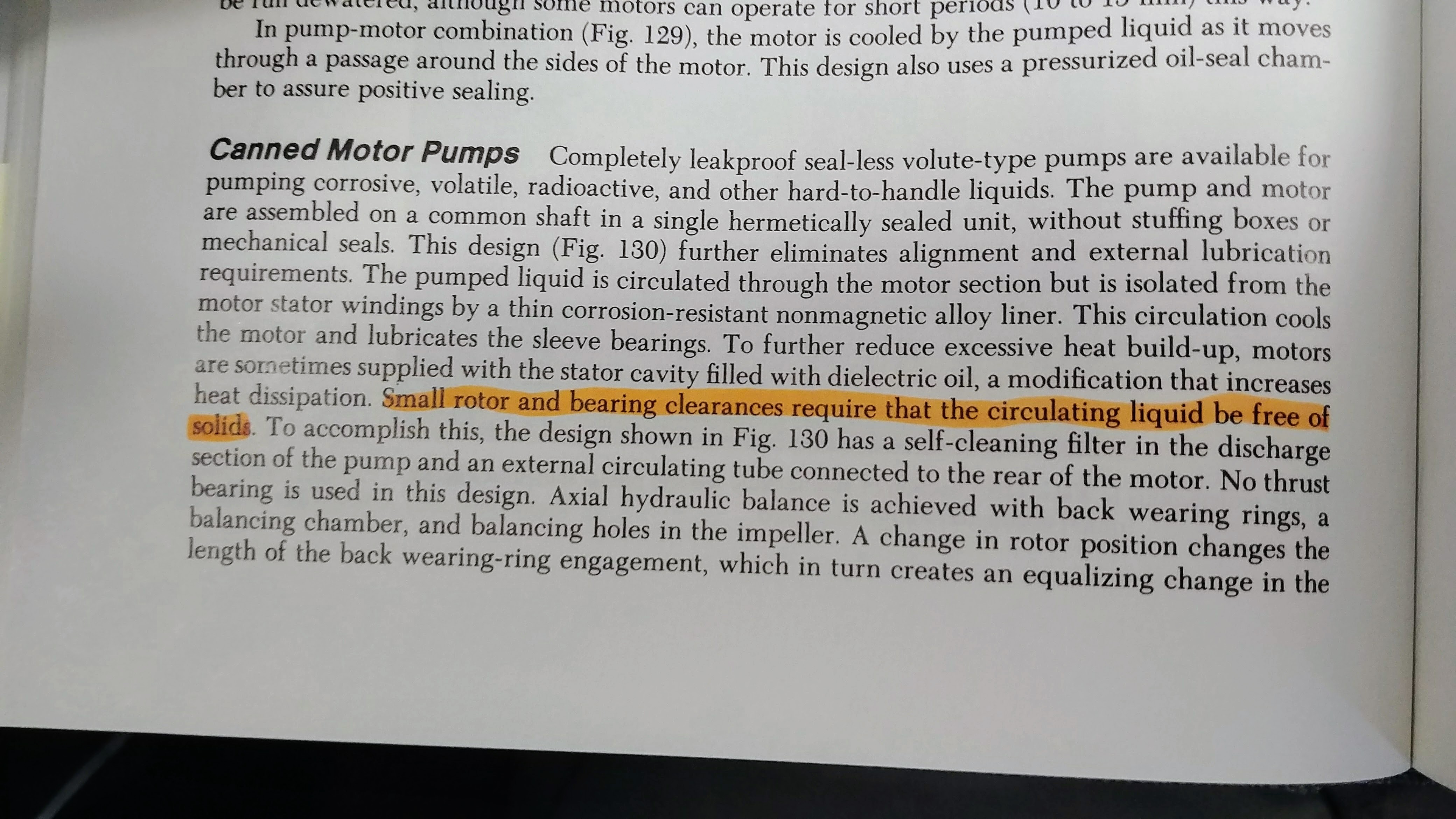

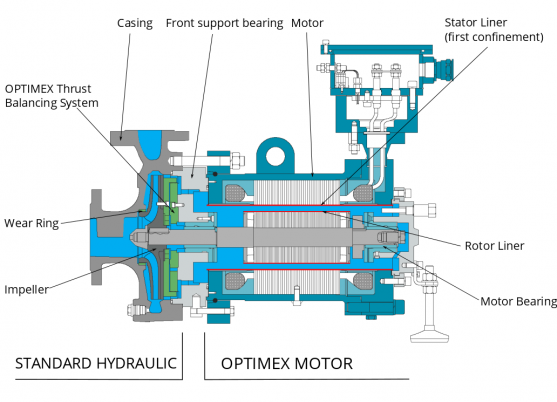

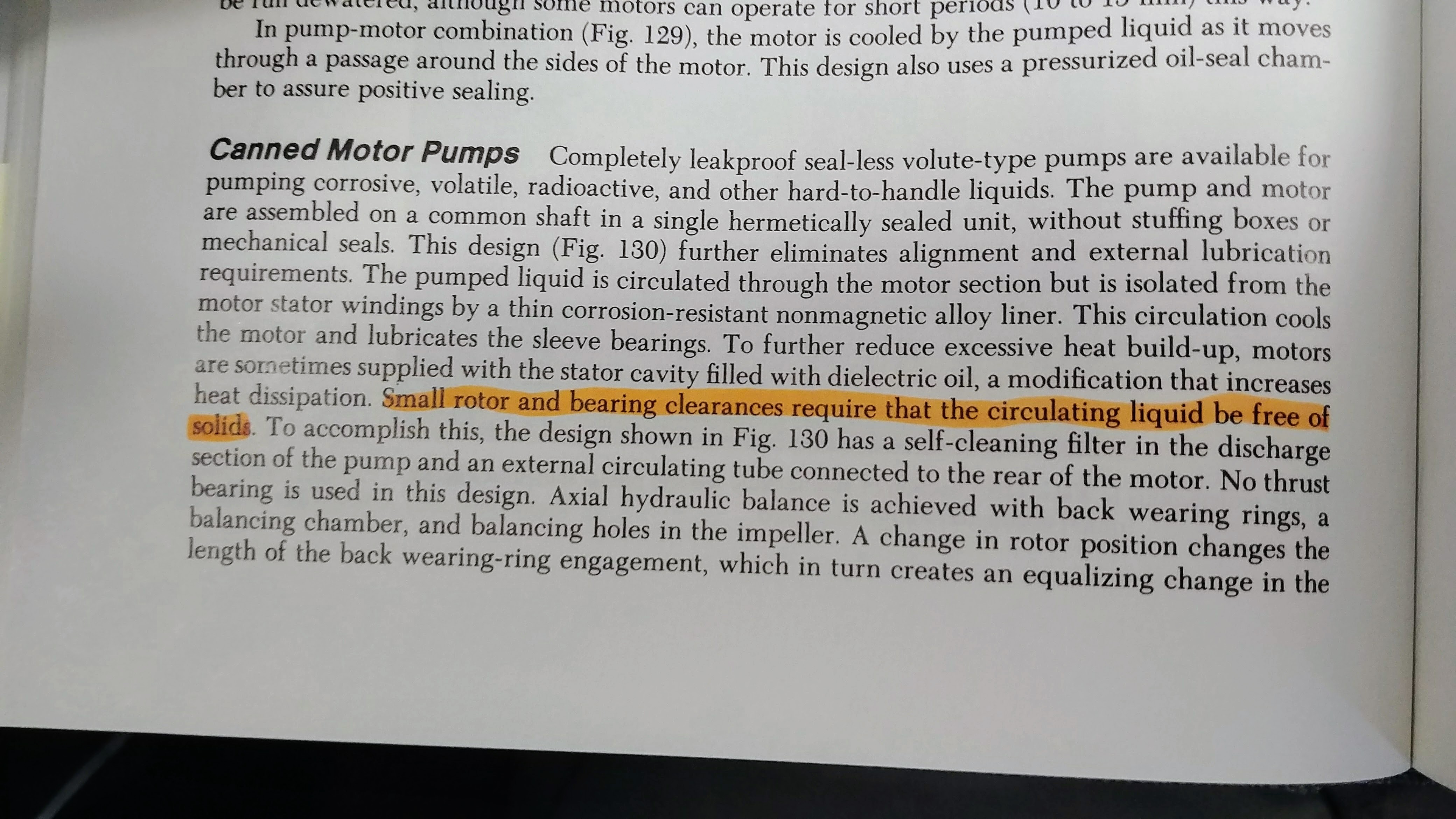

For anyone interested attached is an illustration of a design similar to the tan pumps. Also attached is some info on this type of design. It's critical to not have solids enter the motor section of these pumps.

augiedoggy

Well-Known Member

Or do as many do and sterilze after the boil? That's what I've done for years with no issues.. I open my valve and let my wort fill the hose,pump and late chiller about 2 mins before I shut off the element then I start to reciculate through my plate chiller right as I shut off the BK element. Then about a minute later I start chilling... Never had an infection from this ever. Plusthe whole DMs issue isn't a factor till the wort falls below 170 anyway..To sterilize the pump and plate chiller. I want to chill as fast as possible after the boil to limit DMS so I sterilize during the boil. I guess I could sterilize them as the boil is starting then leave them connected the whole time.

What is your workflow for sterilizing the pump and chiller at the end of the boil?

I want to make sure I understand your comment about DMS. Are you saying as long as you are above 170 that DMS isn’t a problem? I thought it was a problem anytime above 140 when you aren’t driving it off with the boil.

augiedoggy

Well-Known Member

I have never heard of dms "reforming" myself after the boil with the wort is still at near boiling temps.. You realize a lot of Aussies don't even bother chilling anymore and thier beer comes out fine.I want to make sure I understand your comment about DMS. Are you saying as long as you are above 170 that DMS isn’t a problem? I thought it was a problem anytime above 140 when you aren’t driving it off with the boil.

Does anyone have an idea if these tan pumps would be compatible with draft beer line cleaning solution? I have a few of these pumps laying around and thinking of using for recirculating BLC solution.

LittlejohnBrew

Well-Known Member

- Joined

- May 2, 2017

- Messages

- 88

- Reaction score

- 23

Does anyone have an idea if these tan pumps would be compatible with draft beer line cleaning solution? I have a few of these pumps laying around and thinking of using for recirculating BLC solution.

I was wondering the same thing. Since you haven't gotten a reply I'll weigh in. I have not personally used BLC with my pumps, but I don't see how it would be an issue. The SDS (link below) states that it is corrosive to metals which is likely due to the alkalinity. However, I don't see any impact on the materials of these pumps especially given the short contact time.

If you want to be conservative though I'd wait until someone else with experience weighs in on this.

https://www.nationalchemicals.com/download/document/141

Similar threads

- Replies

- 8

- Views

- 1K

- Replies

- 2

- Views

- 1K