hungrymonkey

Well-Known Member

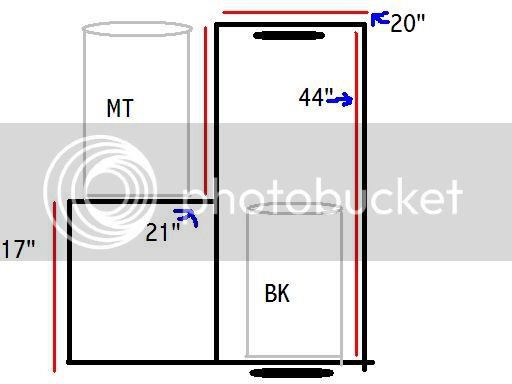

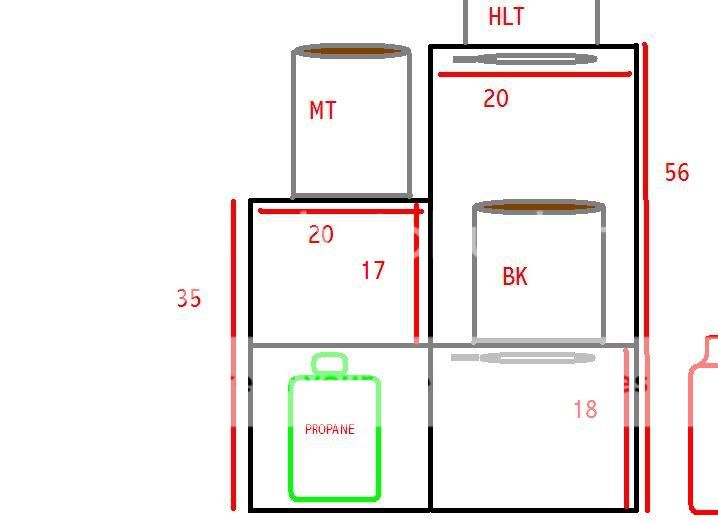

Here is my plan so far. This will be with 1.5" square tubing. Using hurricane burners and hopefully kettles.

The kettles I found through morebeer are 14" tall. I gave it 3 extra inches for the boil kettle, in case I use a keggle. The cooler mash tun is an approximate 21" for a converted 10 gallon cooler.

I put the boil kettle low. I am contemplating movie it up high enough to clear a carboy to make it easier to transfer.

Thoughts, opinions, or criticism is greatly appreciated.

I do have a mig and the ability to cut the tubing.

The kettles I found through morebeer are 14" tall. I gave it 3 extra inches for the boil kettle, in case I use a keggle. The cooler mash tun is an approximate 21" for a converted 10 gallon cooler.

I put the boil kettle low. I am contemplating movie it up high enough to clear a carboy to make it easier to transfer.

Thoughts, opinions, or criticism is greatly appreciated.

I do have a mig and the ability to cut the tubing.